At K, Kuori is presenting a material that redefines the concept of sustainability in the plastics sector: the HC Compound. The bioplastic is home compostable, bio-based, and elastic—a combination that has been hard to find until now. It was developed to combat microplastics at their source while meeting the functional requirements of modern applications.

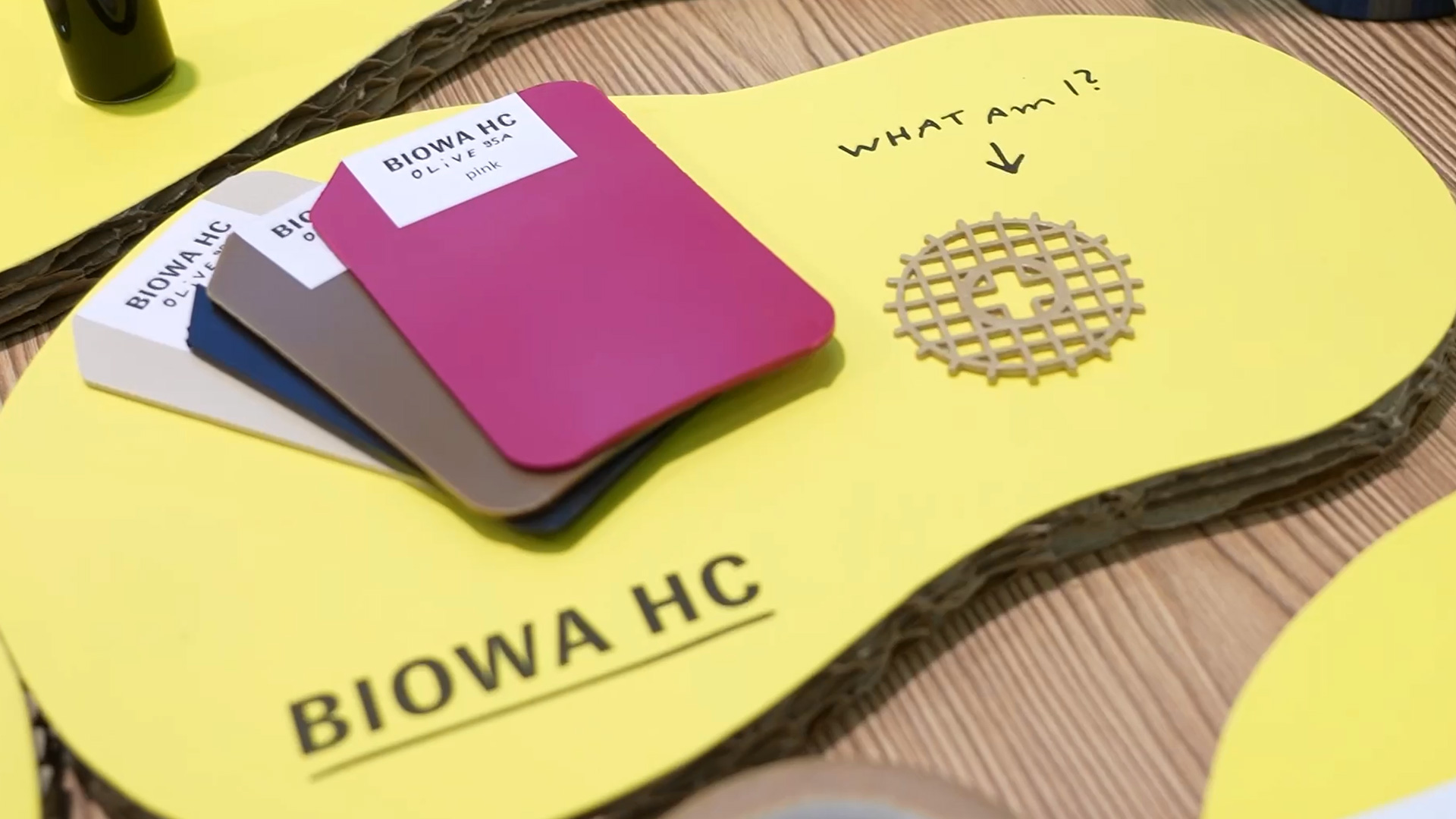

At the heart of the new material is a combination of thermoplastic elastomers (TPEs) and biological fillers such as olive pits or walnut shells. These nature-based components often come from by-products of food production – such as olive oil production – and give the compound its biological basis. Crucially, the material decomposes completely and without leaving any residue. It is not only industrially degradable, but also degradable in domestic compost. This puts Kuori one step ahead of many suppliers who limit themselves to bio-based but not fully degradable plastics. The composition of the material is reminiscent of a finely tuned recipe – Kuori likes to compare the production process to baking a cake, where each additive influences the consistency and functionality. In addition to bio-fillers, biopolymers and additives are used that influence color, strength, or elasticity without compromising ecological degradability.

Despite its biological origin, the HC Compound is hardly inferior to conventional materials such as TPE or EVA in terms of performance. It exhibits comparable properties in terms of elasticity, dimensional stability, and durability. The only differences are in water absorption and abrasion, which Kuori is continuously researching to optimize. The goal is to further develop biopolymers so that they can also withstand demanding applications – from outdoor products to mobility. The company is thus deliberately positioning itself outside the pure packaging market. While many bioplastics manufacturers focus on rigid hard plastics or film solutions, Kuori concentrates on elastic high-performance materials. This opens up fields of application in which sustainable alternatives were previously hardly available – such as shoe soles, handles, or soft-touch elements in vehicle interiors.

The possible applications are wide-ranging. Kuori is already working with well-known partners, including Decathlon, for whom sustainable shoe outsoles have been jointly developed. The elastic biomaterials are also used in sports equipment such as ping-pong bats. The material offers the necessary flexibility and grip without resorting to petroleum-based polymers. In addition, Kuori is involved in pilot projects with the automotive industry, for example with Volkswagen. The focus here is on soft-touch components in the interior that are combined with textiles. The aim is to replace plastics that release microplastics through abrasion. This aspect is particularly relevant for frequently touched surfaces such as armrests or door panels.

A key driver of this development is the problem of microplastics. Every step taken with synthetic shoe soles, every bit of abrasion from a bicycle tire, or every time plastics are rinsed out in the household, tiny particles are released into the environment. Kuori addresses this problem by designing the material so that it can completely decompose at the end of its life. It thus not only contributes to the reduction of plastic waste, but also actively prevents the creation of new sources of microplastics.

The company's research shows that biodegradable elastomers will play a key role in material development in the future. Depending on the area of application, the composition of the HC Compound can be individually adapted – for example, in terms of UV stability, hardness, color, or abrasion resistance. This results in tailor-made solutions that can compete with conventional materials without accepting their ecological disadvantages.

With its focus on home-compostable, bio-based, and elastic materials, Kuori is positioning itself as an innovative supplier in the field of sustainable polymers. The HC Compound shows that ecological responsibility and technological performance do not have to be contradictory. Through close cooperation with industry partners and the consistent further development of its formulations, the company is creating a basis for making plastics more climate-friendly and recyclable in the long term.