Replace Plastics develops patented recycling process for complex plastics

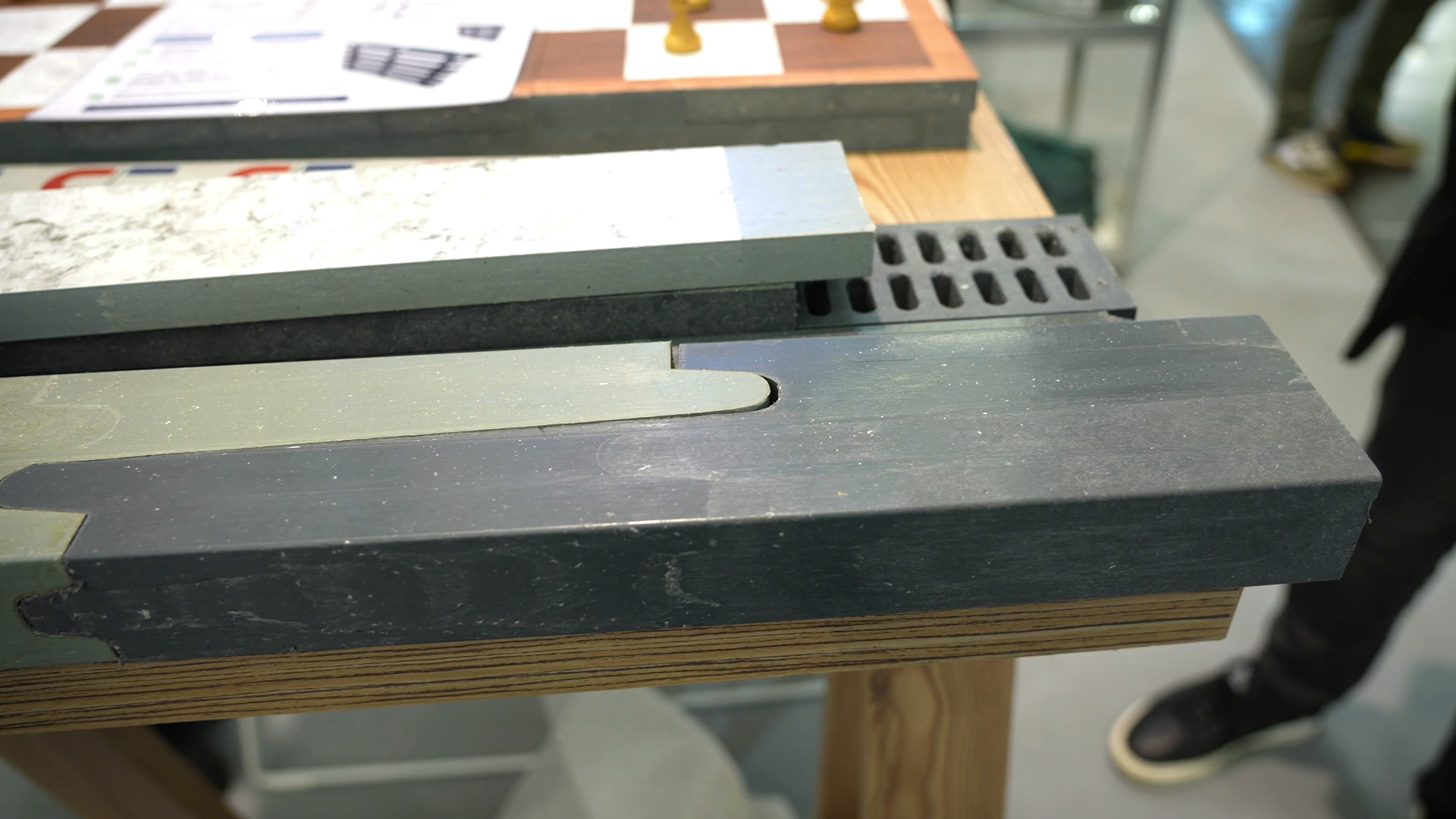

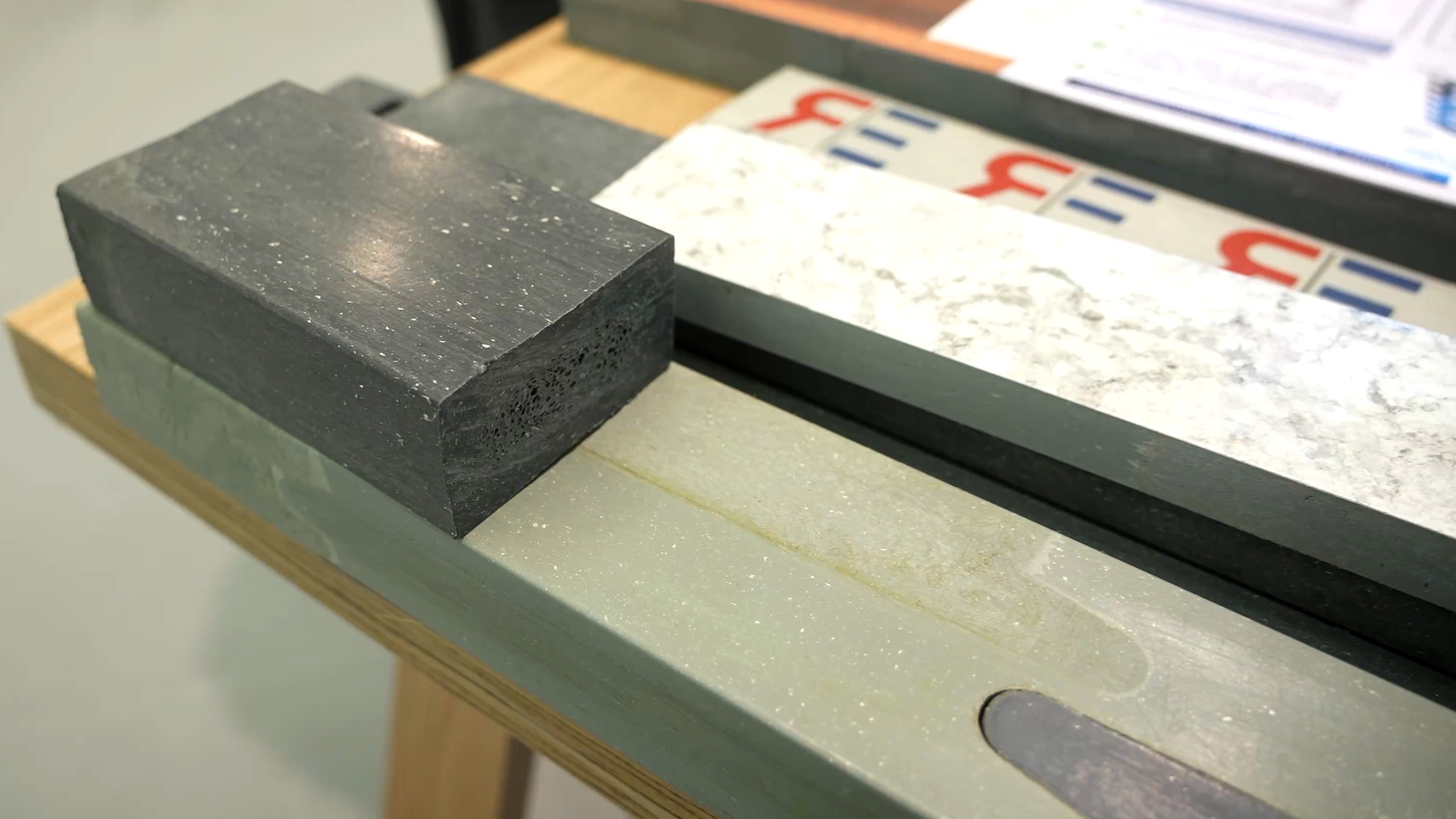

by F. Zuber - 2025-10-12In the plastics industry, complex material composites are considered one of the biggest obstacles to effective recycling. Due to their composition, many plastics are incinerated or sent to landfill – with a significant impact on the environment and climate. The process presented here shows that there is another way: through targeted mixing and stabilization, even plastic streams that are difficult to separate can be recycled. The principle is based on a patented approach in which different types of plastics are combined to create a stable structure. This new material base is not only recyclable, but can also be reprocessed in a closed loop. The developer describes it as a process similar to that used for concrete: a mixture of different components that together form a robust, durable bond.

CO₂ savings through innovative mixing and stabilization process

A key advantage of the technology lies in its ecological balance. The new process reduces CO₂ emissions many times over compared to incineration. The developer claims up to a thirtyfold improvement in the climate balance, as the plastic is not destroyed but kept in circulation. The method not only avoids emissions, but also reuses existing materials. Every kilogram of recycled plastic replaces newly produced material, thereby reducing dependence on fossil raw materials. The positive effect is particularly significant in large-volume applications, such as in the construction or logistics industries.

High resistance to UV radiation and microplastics

In addition to its recyclability, the material is characterized by its high durability. In tests, it showed remarkable resistance to UV radiation and mechanical stress. These properties open up new fields of application, for example in durable outdoor products such as garden furniture or building materials. Another effect of the patented process is that the surface of the material has a special structure that reduces microplastic formation. The company is thus addressing one of the most pressing environmental problems in the industry. The material remains stable, decomposes less, and contributes to reducing plastic particles in the environment.

Plastics in use in construction, logistics, and the furniture industry

The process makes it possible to transform previously unused plastic waste into high-quality products. Whether in construction as a substitute for wood or concrete, in logistics as resilient plastic components, or in the manufacture of durable furniture—the potential is considered enormous. The combination of recyclability, stability, and CO₂ reduction makes the approach a forward-looking contribution to a more sustainable plastics industry.

The presentation at the trade fair makes it clear that progress in the plastics industry is not achieved solely through new materials, but through intelligent processes that make better use of existing ones. This technology gives plastic a second life – and with a significantly lower ecological footprint.

Replace Plastics is shaping the future of the plastics industry: recycling as a key technology

The industry is at a turning point. The ability to recycle complex plastics economically and sustainably could be crucial for the future viability of the entire industry. The process presented shows how the circular economy can be implemented in practice – with technical precision, ecological impact, and economic relevance. With this approach, plastic is no longer a problem material, but a resource that can be used multiple times. A contribution that has a signal effect far beyond the trade fair.