Hy-Lok D – your partner for fluid systems and complete system solutions

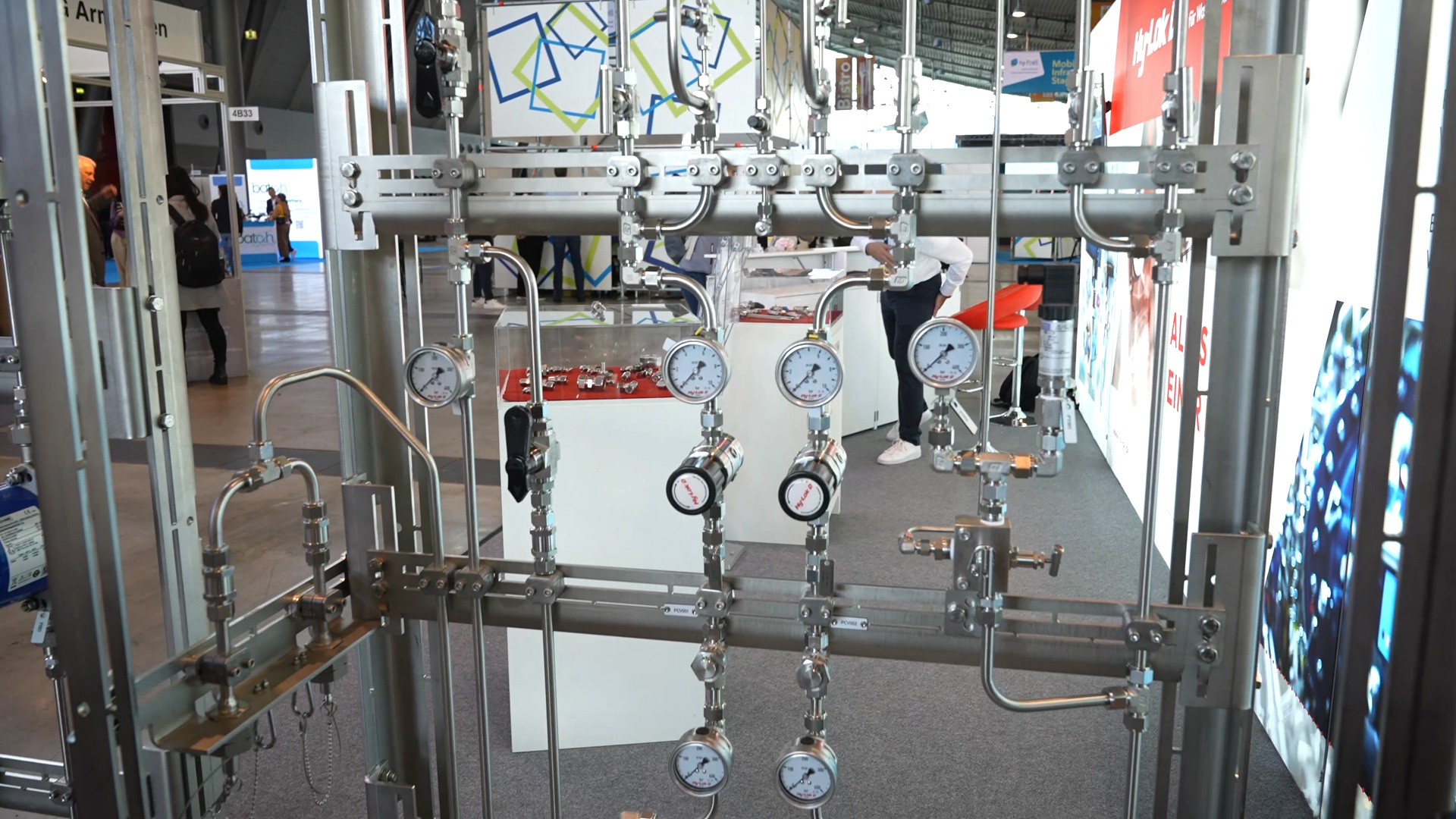

by F. Zuber - 2025-10-16Hy-Lok D Vertriebs GmbH is a reliable specialist for fluid systems, individual components, and complex plant solutions. As the exclusive representative of Hy-Lok in Germany, Austria, and Switzerland, the company offers high-quality products. In addition to standardized components, Hy-Lok D supplies complete system solutions – from the initial concept and technical design to the finished installation. Customers benefit from comprehensive advice, precisely tailored piping dimensions, and professional support during installation. Hy-Lok D sees itself as a system provider that creates complete fluid systems from individual components – especially where hydrogen plays a role. From the initial project idea to engineering and the finished plant – including validation and safety testing.

Hydrogen places the highest demands – Hy-Lok D guarantees tightness and durability

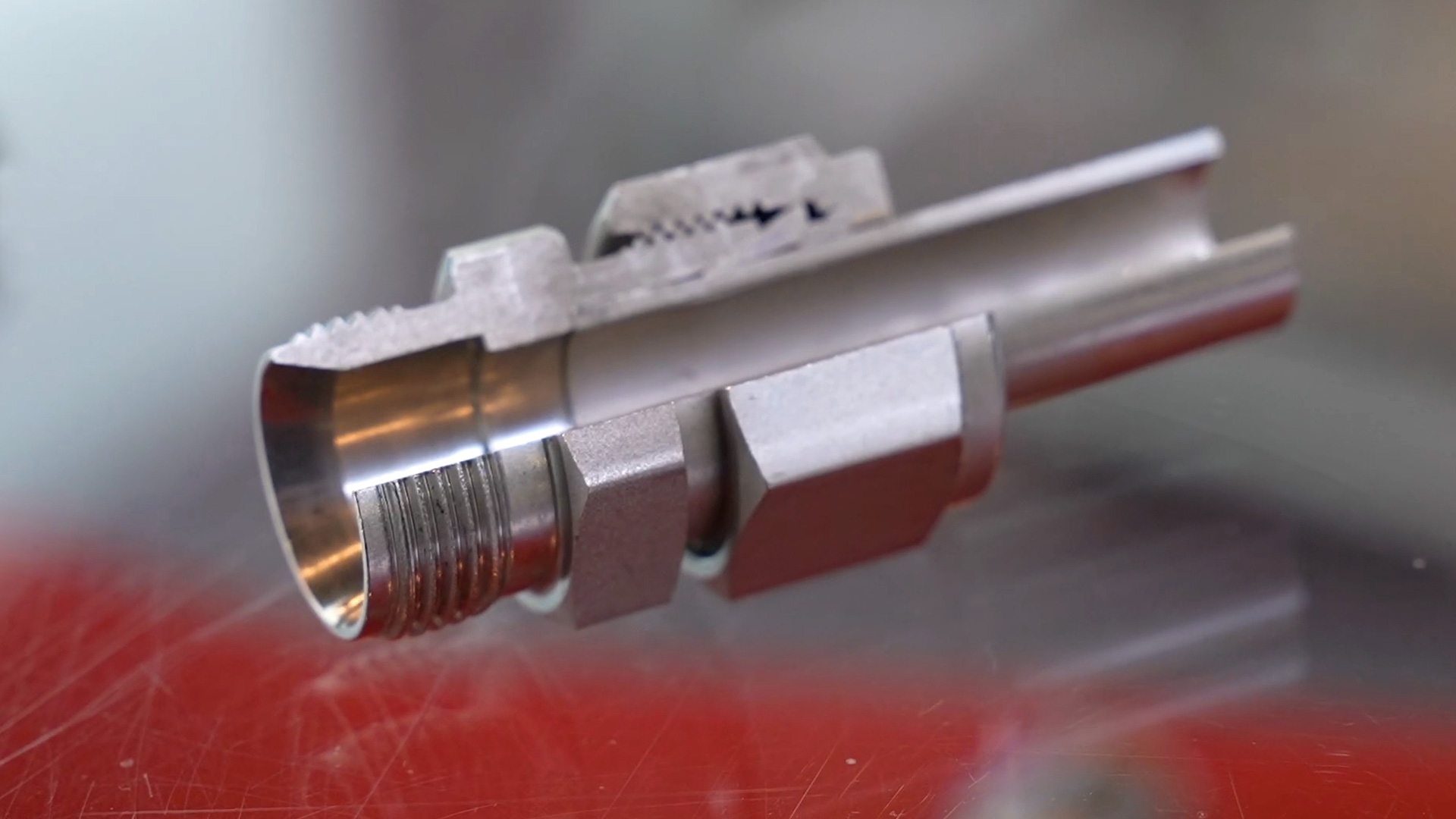

Hydrogen is the smallest and most diffusible molecule – a fact that places enormous demands on sealing systems and materials. And this is precisely where Hy-Lok D's strength lies. The company relies on compression fittings in a two-compression-ring design that provide a completely metallic seal. This design deliberately avoids the use of elastomers and ensures high resistance to temperature and pressure fluctuations. The material used is austenitic stainless steel grade 316 or 316L, which is considered the industry standard for hydrogen-compatible systems. These materials resist both corrosion and penetration by hydrogen molecules – a basic requirement for safe fluid systems. This results in durable, robust, and reliable connections that can be used in energy technology as well as in chemical or industrial processes.

Hy-Lok D from component to system – solutions with technical depth

The Hy-Lok D portfolio ranges from standardized individual parts to individually configured components and complex assemblies. One example is a modular gas transfer system developed by Hy-Lok D in collaboration with a customer. This system assembly enables the safe transfer of hydrogen gas – for example, from a cylinder bundle or trailer to another container. The gas pressure can be kept constant or specifically reduced via a two-stage pressure reduction process. The system filters the gas, reduces pressure fluctuations, and ensures safe transfer—based on precise stainless steel valve and screw connection technology.

Hydrogen systems with professional installation and technical support

Hy-Lok D offers not only products but also comprehensive technical service. A network of experienced partner companies ensures that systems are professionally installed in Germany, Austria, and Switzerland. This means that every project can be individually supervised and implemented – regardless of size or complexity.

The quality of installation is particularly important to Hy-Lok D. In hydrogen systems, precise workmanship is crucial for the tightness and thus the safety of the entire system. Technical advisors support customers directly on site, check connections, and ensure that every installation meets the high requirements of hydrogen technology.

Hydrogen technology as a market of the future – Hy-Lok D invests in sustainable solutions

Hy-Lok D has been working intensively on hydrogen-compatible connection technology and system integration for many years. The demand for corresponding components and complete solutions is growing steadily – especially in the energy industry, among industrial companies, and in mobility. For Hy-Lok D, hydrogen is a central component of future energy systems. Even though the large-scale implementation of hydrogen projects is being delayed in some places, the company is optimistic about the development. Thanks to early specialization, technical experience, and direct cooperation with customers and research institutions, Hy-Lok D has a deep understanding of the requirements in the hydrogen sector. This puts the company in an ideal position to actively shape the energy transition – with safe, durable, and precise fluid systems for a sustainable future.