Mercedes-Benz GenH2 Truck – liquid hydrogen as the key to long-distance transport

by B. Velonavy - 2025-10-16The Mercedes-Benz GenH2 Truck symbolizes the future of emission-free road freight transport. The vehicle is based on a fuel cell system from Cellcentric, the joint venture between Daimler Truck and Volvo. The drive system uses liquid hydrogen (LH₂) as an energy source – a medium with a particularly high energy density that enables long ranges and short refueling times. With a range of more than 1,000 kilometers per tank, the GenH2 addresses the typical requirements of long-distance transport, where payload, range, and availability are crucial. The transport industry is facing radical change. Increasing emission targets and CO₂ limits are forcing manufacturers and operators alike to rethink their approach. While battery-electric trucks are suitable for short distances and inner-city logistics, long-distance transport requires a different solution. This is exactly where Mercedes-Benz comes in with its fuel cell – a technology that combines high performance, long distances, and fast refueling.

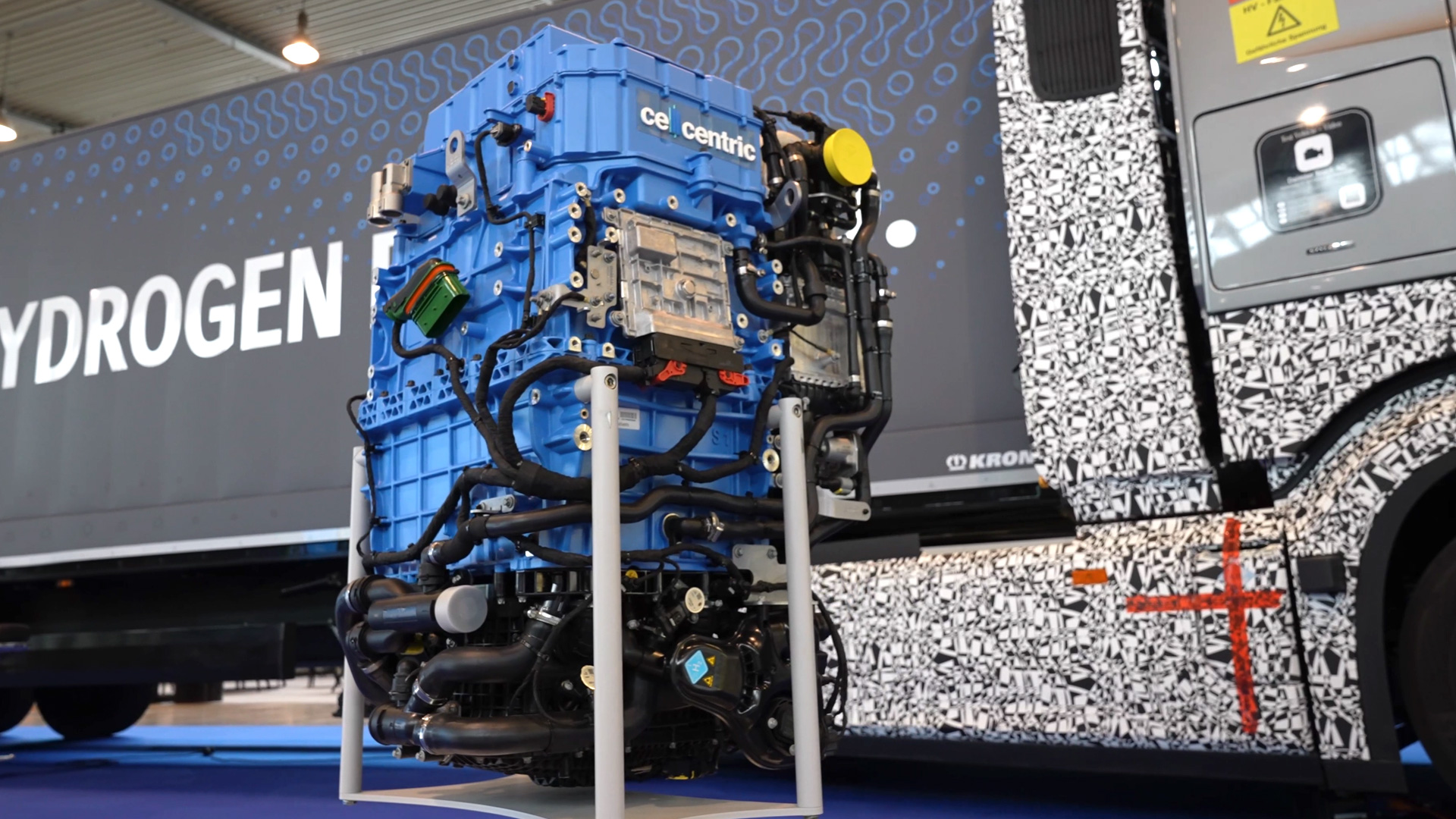

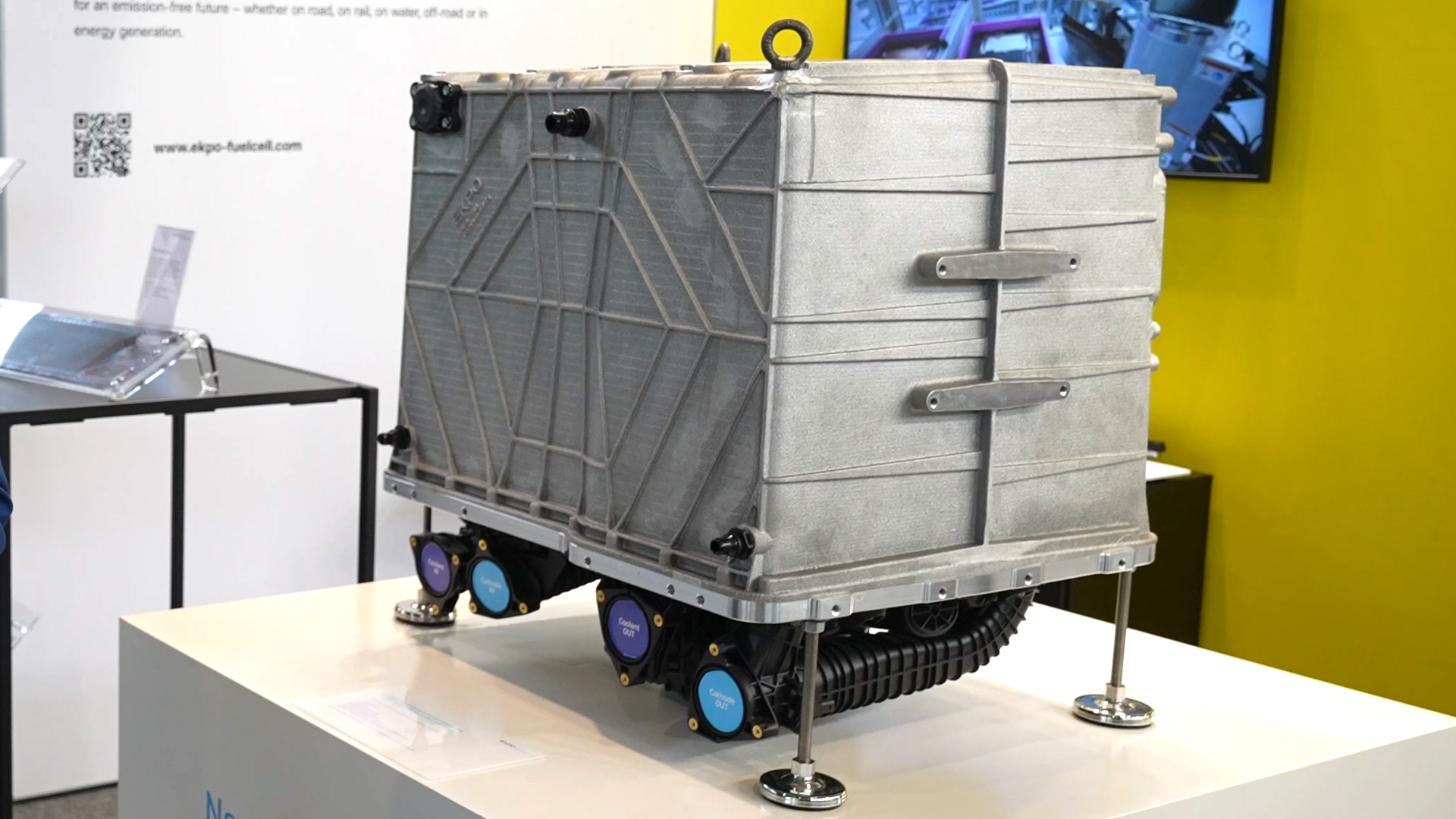

Cellcentric fuel cell – GenH2 technology center

At the heart of the GenH2 truck is the fuel cell from Cellcentric. It converts hydrogen into electrical energy and supplies the drive with constant power, even during long operations and under heavy loads. The systems are designed for durability and efficiency – developed for millions of kilometers on the road. Prototypes of the vehicle have been undergoing intensive testing since 2021. Among other things, the “Hydrogen Record Run” demonstrated that a fully loaded 40-ton truck can cover over 1,000 kilometers in real-world operation. The test results confirm that the fuel cell achieves ranges comparable to conventional diesel engines, but without CO₂ emissions. The current development program spans several generations. Following successful pilot phases, around 100 GenH2 trucks are to be integrated into customer fleets from the end of 2026. This testing under real-world conditions will provide valuable data for the planned series production, which is scheduled to start in the early 2030s.

Liquid hydrogen – energy carrier for long distances

In contrast to gaseous hydrogen, Mercedes-Benz relies on liquid hydrogen for the GenH2. The decisive advantage lies in the higher energy density: LH₂ requires significantly less volume and thus enables greater ranges without sacrificing payload. In addition, refueling remains familiar to drivers – a process that takes just a few minutes, comparable to diesel. This technology makes the truck a real alternative for international long-distance transport. The liquid hydrogen is stored in special cryogenic tanks at minus 253 degrees Celsius and provides the energy needed to move heavy loads over long distances. For freight forwarders, this means a predictable range combined with climate-neutral operation – a decisive step towards the transformation of logistics.

Infrastructure and energy supply as the key to success

Developing the vehicle is only part of the challenge – building the necessary infrastructure is just as important. For heavy-duty transport, relatively few but strategically placed hydrogen filling stations along the main transport axes are sufficient. Industry experts estimate that around 2,000 stations will be needed in Europe, about half of which will be for liquid hydrogen. At the same time, international supply chains are emerging that bring green hydrogen from sun- and wind-rich regions to Europe. Mercedes-Benz is working with partners such as Masdar in the United Arab Emirates, which is building facilities for the sustainable production of LH₂. The Japanese industrial group Kawasaki, which has experience in cryogenic ship transport, is involved in transport and storage. The goal: a globally networked system that makes green hydrogen available where it is needed – at filling stations along European logistics routes.

Economic efficiency, scaling, and political framework conditions

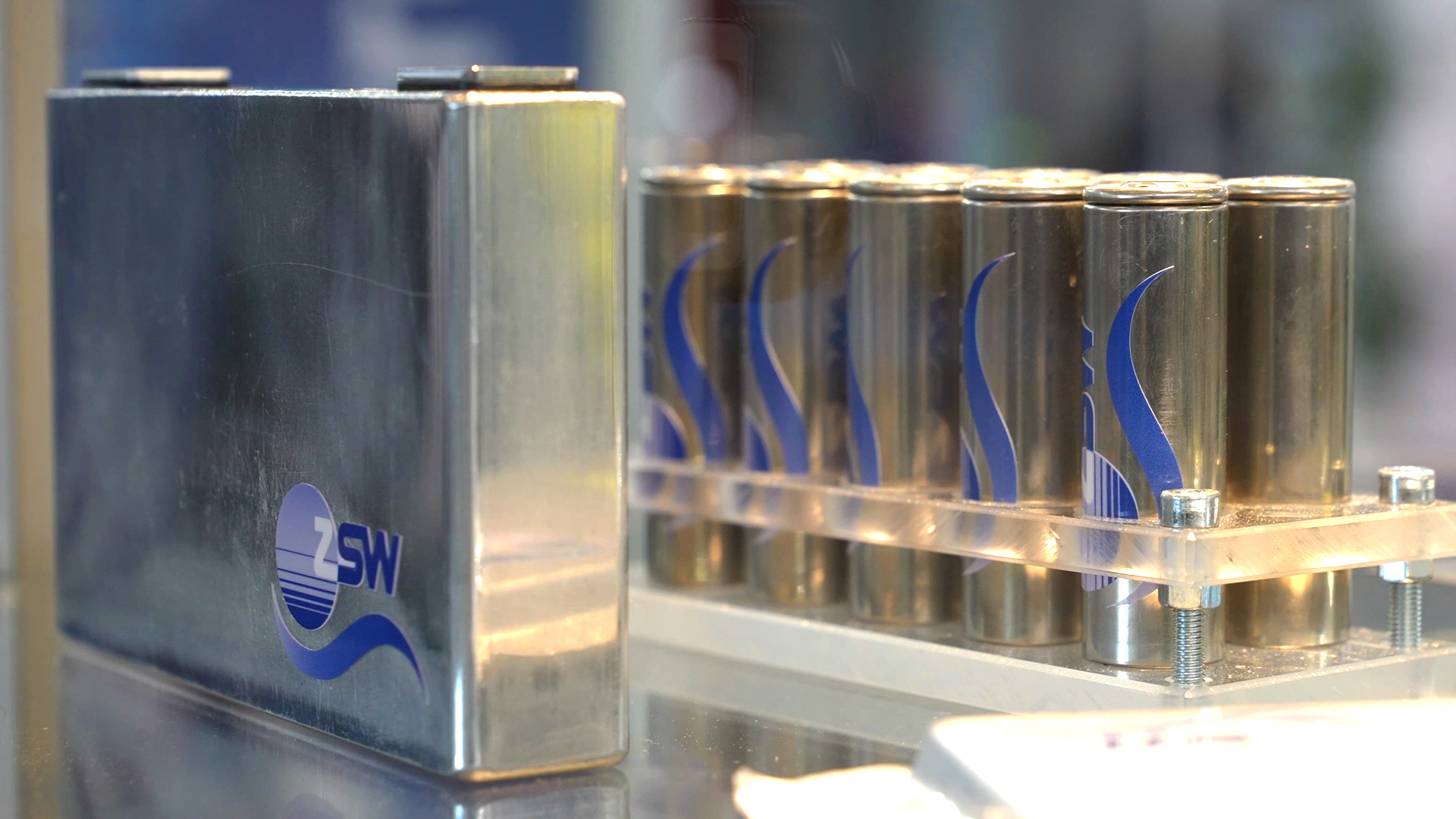

Economic efficiency is the deciding factor in the commercial vehicle business. For freight forwarders, the total cost of ownership – i.e., the total costs over the lifetime of a vehicle, including purchase, maintenance, and energy costs – is what counts. Currently, the costs for fuel cell vehicles and hydrogen are still higher than for diesel, but they are falling significantly as production volumes increase. Subsidy programs, tax breaks, and toll exemptions are intended to accelerate the market ramp-up by 2030. In addition, fuel cell vehicles score points for their lower noise levels, cleaner emissions, and reduced maintenance costs – a plus for the environment, cities, and fleet operators.

Perspective – the GenH2 Truck as a bridge to the future

The Mercedes-Benz GenH2 Truck shows how climate-neutral long-distance transport can be made technically and economically feasible. The combination of Cellcentric fuel cells, liquid hydrogen, and industrial manufacturing creates a platform that can replace diesel trucks in the long term. This requires coordinated cooperation between vehicle manufacturers, energy suppliers, politicians, and freight forwarders.