In hydrogen production, it is not only the efficiency of the electrolysis cells that determines the success of a plant – mechanical components such as springs also play a central role. The long-established manufacturer Christian Bauer from Welzheim specializes in high-precision disc springs, which have become indispensable in modern hydrogen systems. With innovative coatings, new materials, and optimized spring characteristics, the company is transferring its expertise from the automotive industry to future technologies for the energy transition.

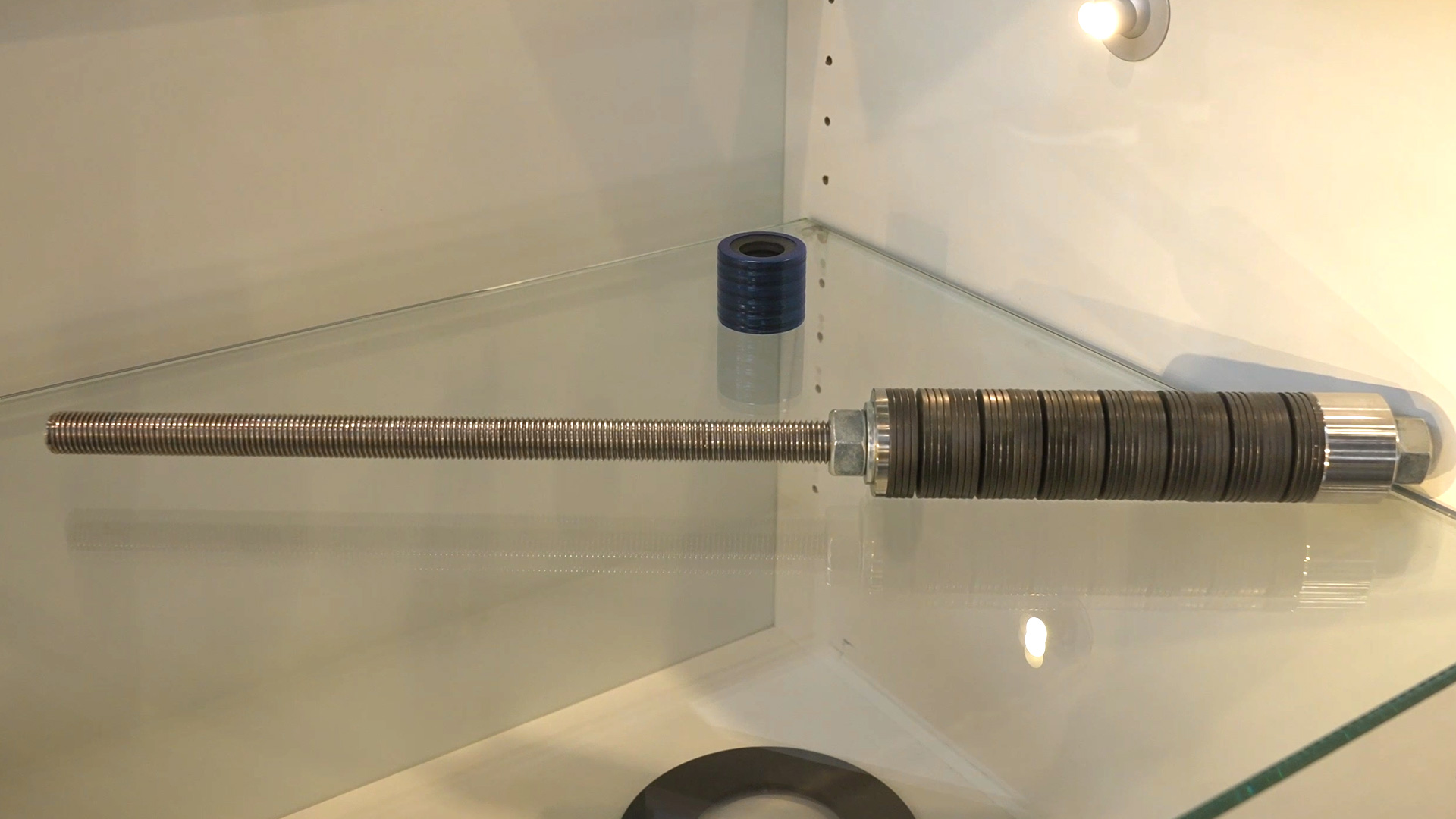

Springs in electrolysers operate under extreme conditions. They must maintain uniform forces over long periods of time while remaining low-maintenance. Christian Bauer disc springs perform this function in tie rods in electrolysers, such as in cellcentric systems for Daimler Truck. Their special feature is their coating, which eliminates the need for lubrication. This not only means clean assembly conditions, but also stable, low-friction force transmission. Lubricated springs, on the other hand, are considered costly and susceptible to contamination. The dry surface significantly reduces friction and wear. Several springs are often combined into packages to achieve the desired characteristic curve – a design that is suitable for both static and dynamic loads, for example in connection with wind power or photovoltaics. At Christian Bauer, every application begins with a precise analysis of the customer's requirements. What forces are at work, how many load cycles are planned, and what are the environmental conditions? Only on this basis are the specifications drawn up, which serve as the basis for design, material selection, and surface treatment.

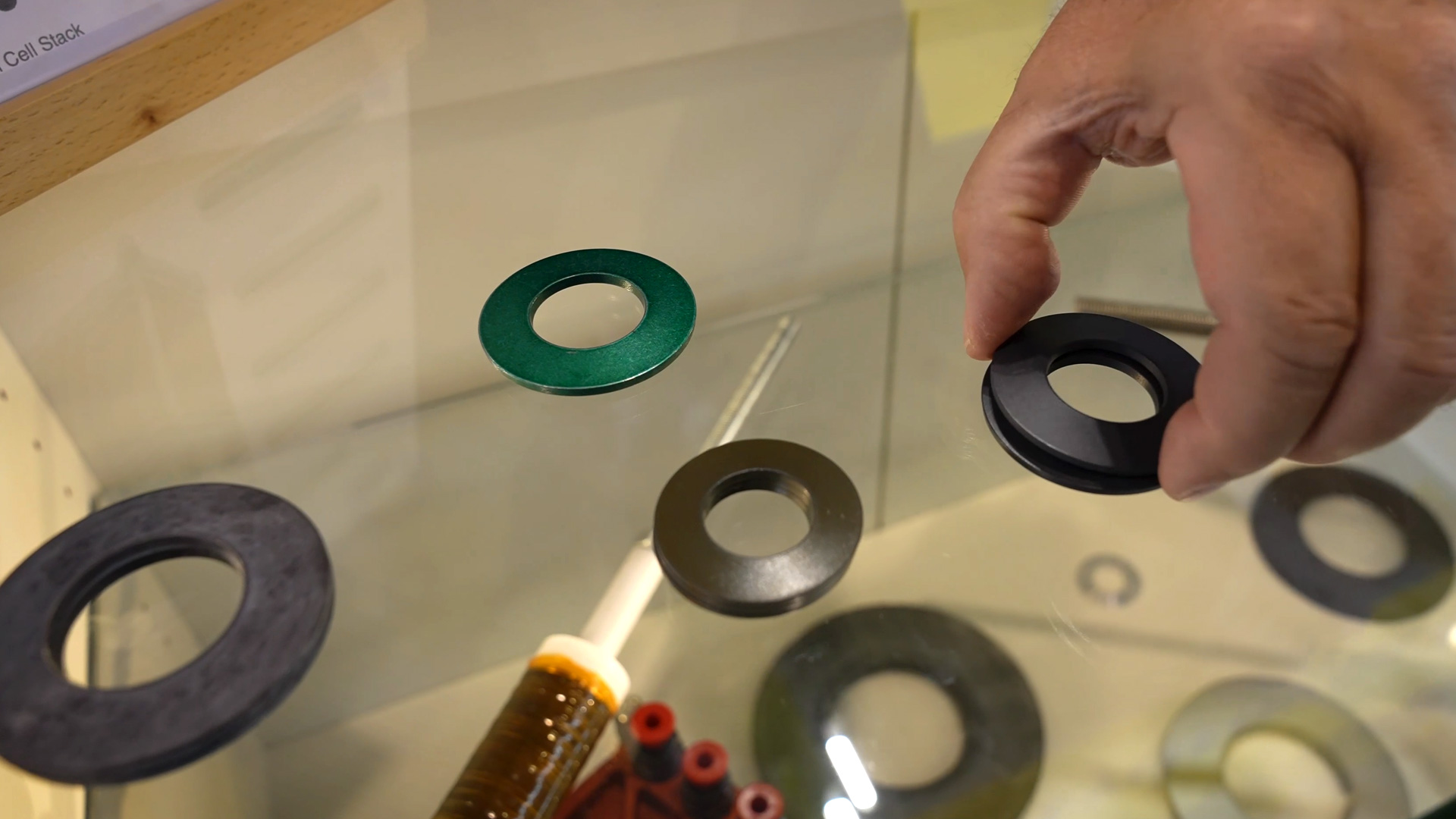

One technological focus is the CB Glide-Tech coating, which was developed specifically for use in hydrogen and energy technology and is legally protected. The goal was to create a surface with permanently low friction – without the use of lubricants. The coating is based on a greenish sliding lacquer, originally known from spindle applications. There, it proved itself through high stability over millions of load cycles. In electrolysers, CB Glide-Tech transfers these properties to stationary systems: friction remains low, force distribution constant, and service life reaches up to ten million load cycles. Depending on the application, different surface structures are used – from phosphated intermediate stages to completely coated variants. The goal: to precisely adapt tribology, i.e., the interaction of friction and wear, to the load situation. CB Glide-Tech has thus established itself as the standard solution for springs in hydrogen-carrying systems. Even with changing temperatures and humidity, the material behavior remains constant—a decisive advantage over conventional lubrication.

In addition to the surface coating, the material itself plays a central role. With High Performance Steel (HPS), Christian Bauer has developed a spring steel that increases service life many times over compared to the established material 51CrV4. While shot peening already reduces wear by a factor of three in standard steels, HPS enables up to ten times this durability. This combination is particularly important for applications in hydrogen systems, where high forces must remain constant over many years. In combination with the CB Glide-Tech coating, this results in springs with high strength, minimal friction, and exceptional durability. The precise design of the spring characteristic curve is a key factor here. Whether linear or slightly degressive, it influences the efficiency of the entire system. In electrolysers, the right characteristics ensure that the pressure on the cell stacks remains constant. The close interlinking of materials technology, coating, and design is one of the company's strengths.

Christian Bauer is currently working on a new spring geometry with a virtually constant characteristic curve. This so-called “cloud-shaped” spring enables a consistent force over the entire working range – ideal for electrolysers where uniform preload is crucial. The result is a flat force-displacement curve that remains stable over long operating times. Initial prototypes show significantly lower force drops than classic linear springs. This development is still in its infancy, but it illustrates the technical direction of the company: precision, material expertise, and continuous research for applications in hydrogen systems. With this focus, Christian Bauer is positioning itself as one of the key suppliers for the mechanical basis of the energy transition—where reliability is invisible but indispensable.