EKPO fuel cell stacks: Precision as the foundation of modern hydrogen technology

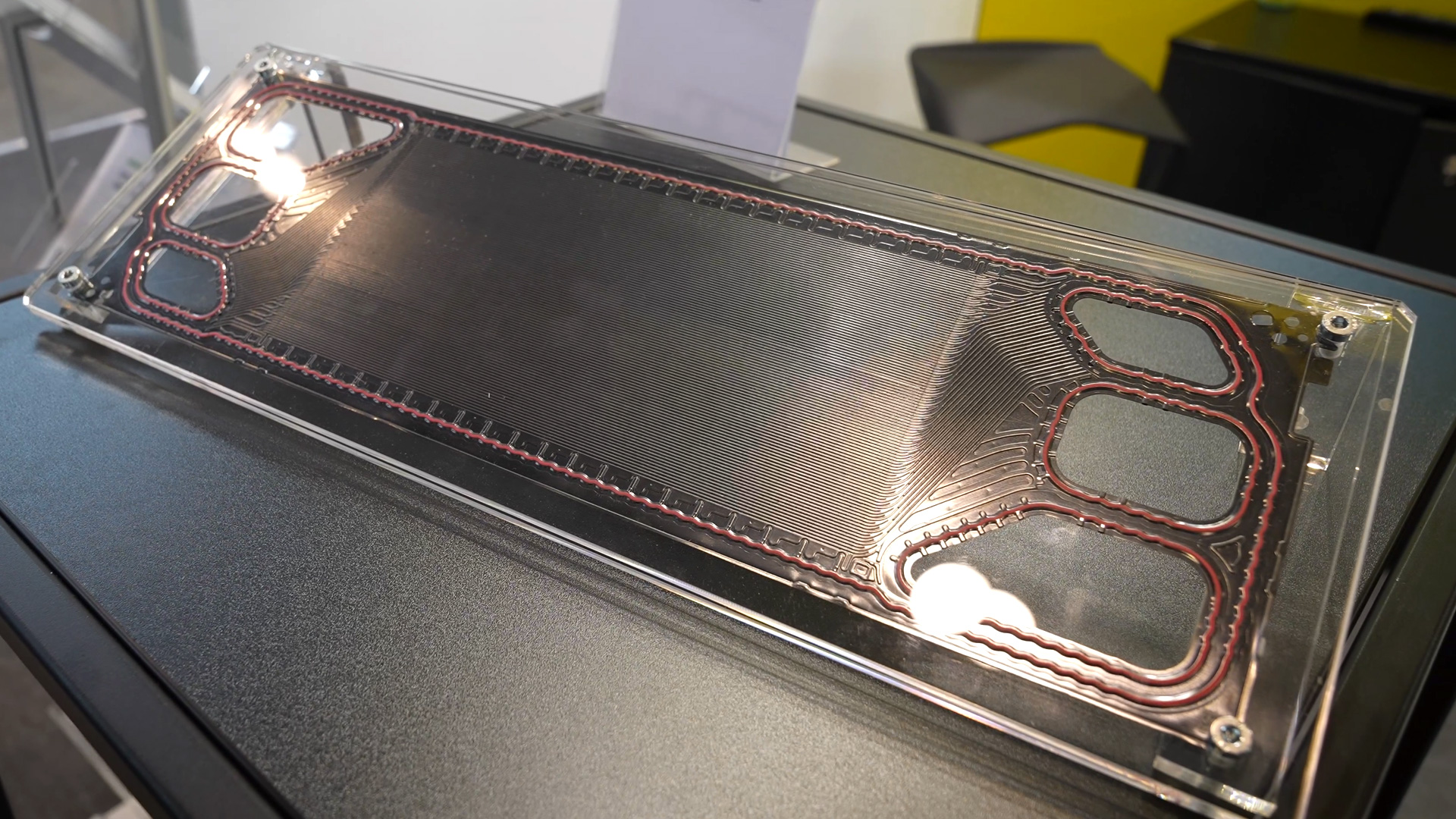

by A. Bergmeier - 2025-10-14The heart of a fuel cell beats in its bipolar plate – and at EKPO Fuel Cell Technologies, it beats with industrial precision. The joint venture between ElringKlinger and OPmobility has turned classic metal forming into a key element of hydrogen technology. Back in the 2000s, ElringKlinger developed processes for punching, forming, and sealing metal plates to make them suitable for high pressures and temperatures. Today, this experience is incorporated into bipolar plates that precisely conduct gases, ensure cooling, and combine electrical conductivity with mechanical stability. The plate is therefore not just a technical detail, but the decisive factor for the efficiency, performance, and service life of the entire fuel cell stack. This is exactly where EKPO comes in—with the same consistency with which other manufacturers optimize combustion engines.

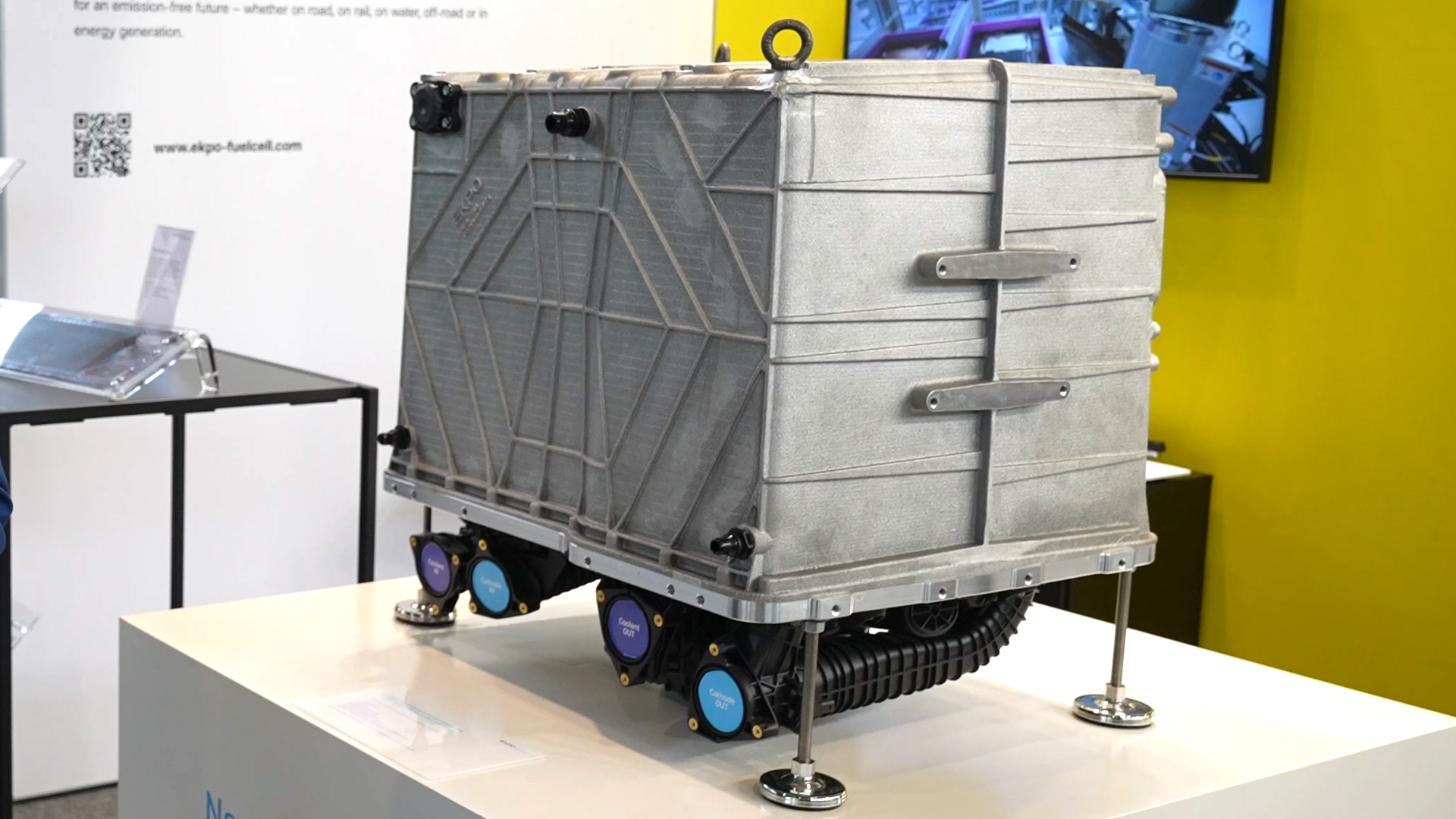

EKPO stack family: From prototype to industrial platform

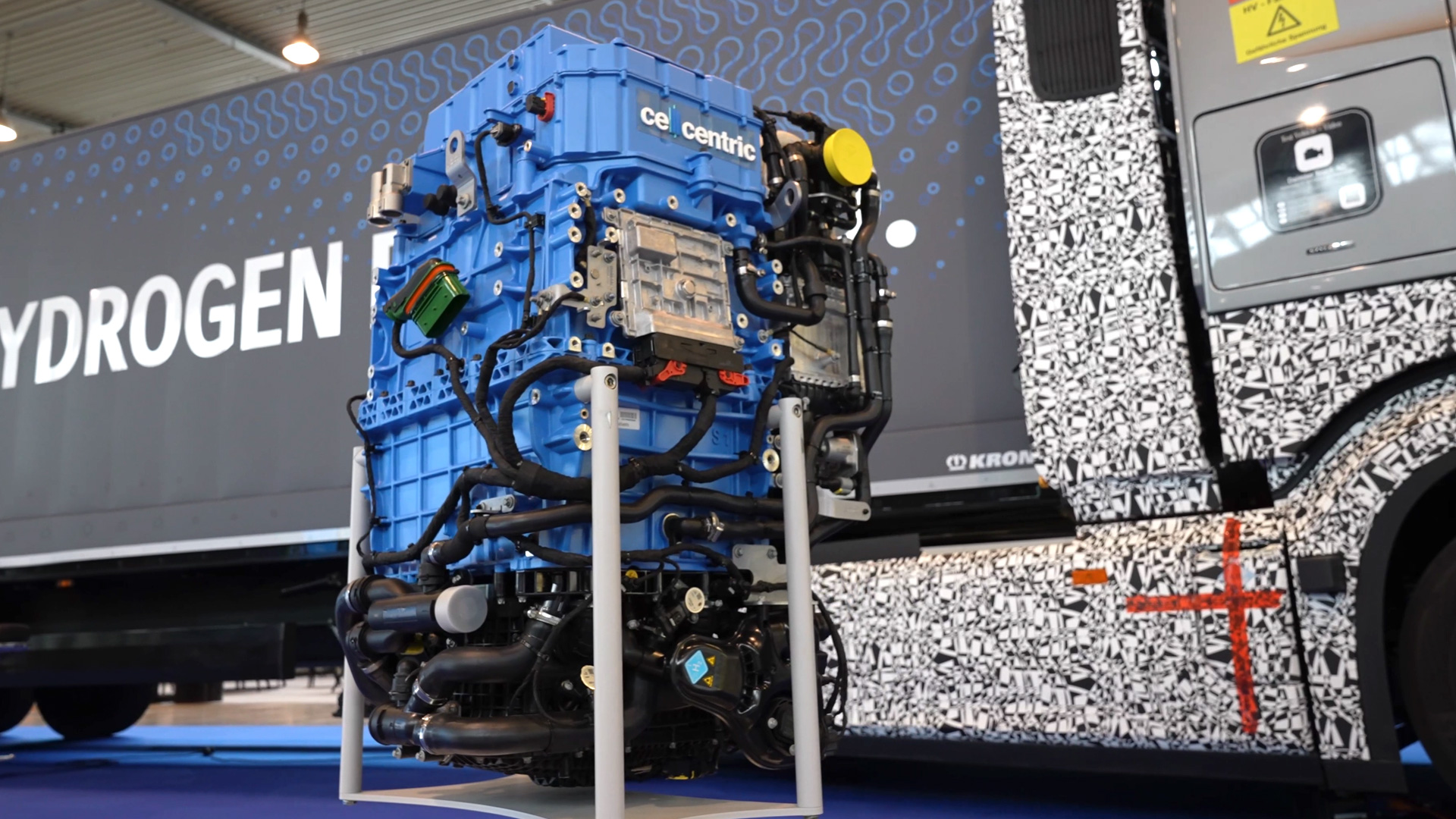

This technology gave rise to a scalable stack family at EKPO: NM5, NM12, and NM20 form a modular system that covers outputs from 15 to 400 kilowatts. The NM20 in particular marks the leap to industrial maturity. Compact in design, robust in continuous operation, and designed for high temperature ranges, it represents the next generation of hydrogen-based energy conversion. A characteristic feature is the standardized media interface at the base of the stack, which simplifies integration and maintenance. Hydrogen consumption remains low and power density high – a combination that improves both range and economy. Whether in trucks, buses, or stationary systems, EKPO focuses on reproducible precision rather than laboratory characteristics.

NM20 delivers 400 kilowatts of power, compressed to series production level

With the NM20, EKPO is introducing the most powerful model in the series to date. 400 kilowatts of electrical power in the smallest of spaces – a value that makes the stack a real series production candidate for commercial vehicles. It operates at higher temperatures, reducing cooling surfaces and simplifying vehicle architectures. This saves weight, installation space, and energy losses. In addition, the stack achieves runtimes of up to 25,000 hours – a decisive argument for continuous operation in heavy-duty logistics, public transport, or industrial energy supply. The NM20 proves that hydrogen systems no longer exist only as pilot projects, but as robust, industrial products.

Hydrogen supply in gaseous and liquid form

Whether gaseous via pipelines or as liquid hydrogen at low temperatures, EKPO's stacks are designed for both forms of supply. This means that the technology remains independent of infrastructure development. Gaseous transport is likely to prevail in the medium term: A pipeline can transmit many times the energy that flows through a high-voltage power line – an advantage in terms of efficiency, grid integration, and energy security. Hydrogen thus becomes a logical addition to decentralized energy grids. From mobility to stationary power supply, a new energy ecosystem is emerging that can be scaled – and in which EKPO plays a central role.

ElringKlinger, OPmobility, and IPCEI as strong partners

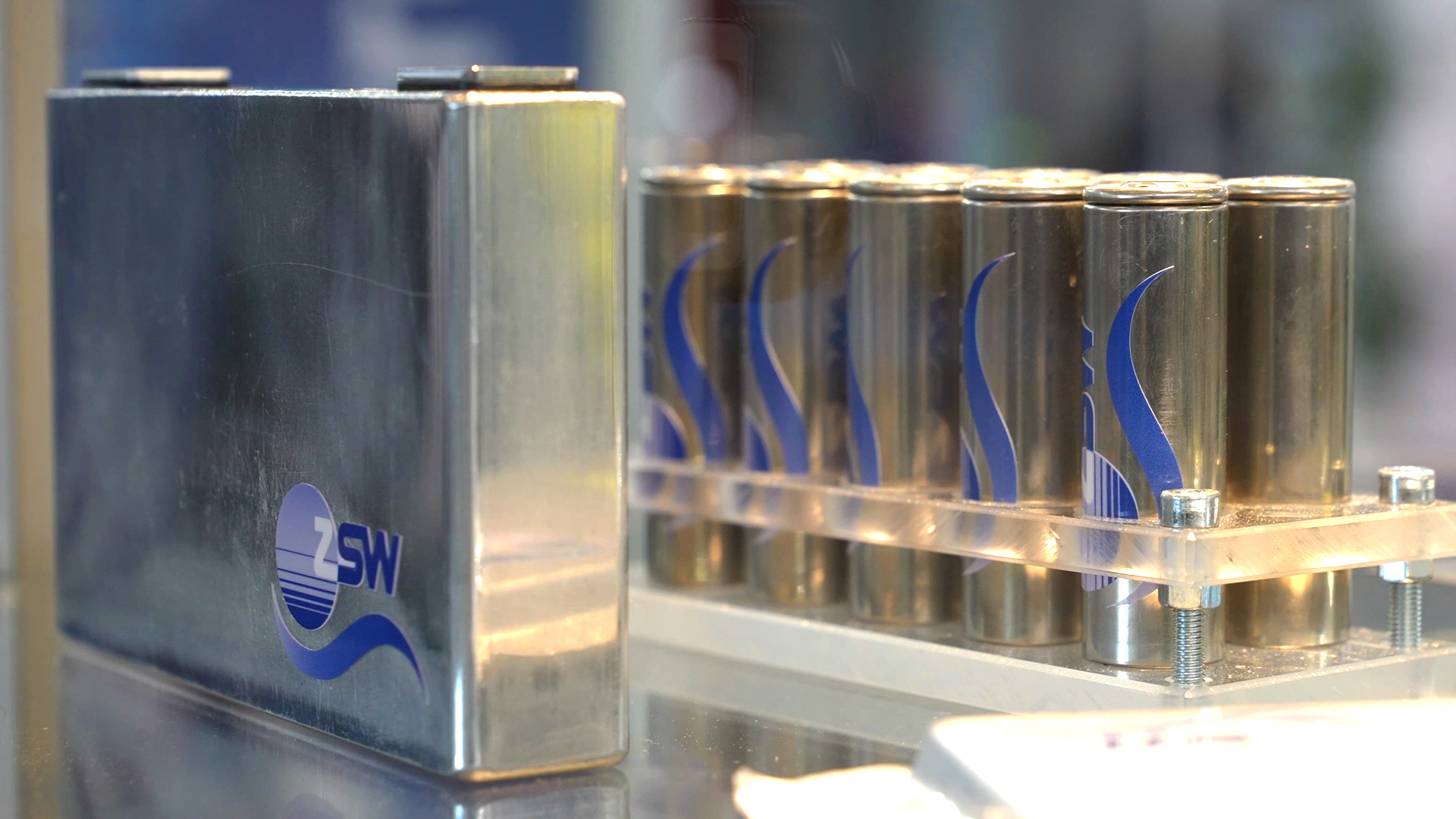

EKPO receives support from its owners. ElringKlinger contributes decades of experience in large-scale production, while OPmobility—formerly Plastic Omnium—adds international presence and financial strength. This combination achieves what many start-ups fail to do: technological agility with industrial stability. In addition, development is being funded through the European IPCEI program. This creates a network of research, production, and market launch that enables EKPO to already manufacture its stacks in series today. By the end of the decade, tens of thousands of units are to be produced annually – for commercial vehicles, stationary energy supply, and critical infrastructure.

Fuel cells on the road to economic viability

The economic threshold is within reach. With hydrogen priced at around six euros per kilogram, fuel cell drives are on par with diesel and battery-electric solutions in terms of cost, according to EKPO. Local production, surplus electricity utilization, and intelligent energy management make this realistic. This shifts the perspective: fuel cells are no longer a project for the future, but a tool for current energy issues. EKPO shows how industrial manufacturing and technological maturity come together – precisely, scalably, and ready for the transition to an emission-free industrial society.