The TruArc Weld from Trumpf is an automated welding system designed specifically for industrial manufacturing processes with changing requirements. At its heart is an integrated seam tracking sensor, which won the Best Award in the joining technology category at a trade fair. This award recognizes a technical solution that significantly simplifies the welding process while enabling high component quality.

The system has been established in the portfolio for several years and has been specifically further developed with the seam tracking sensor. The background to this development is concrete feedback from practical experience, especially from companies that are confronted with a shortage of skilled workers and increasing variety in production.

The Best Award in the joining technology category is the result of further development that is consistently oriented toward real-world requirements. In welding technology, the shortage of qualified young talent has been a central problem for years. At the same time, demands for precision, repeatability, and documentation are increasing. TruArc Weld addresses this issue by significantly reducing the programming effort and making the welding process more robust. The seam tracking sensor is not to be understood as an additional function, but as an integral part of the system. It enables stable results to be achieved even with component tolerances or positional deviations.

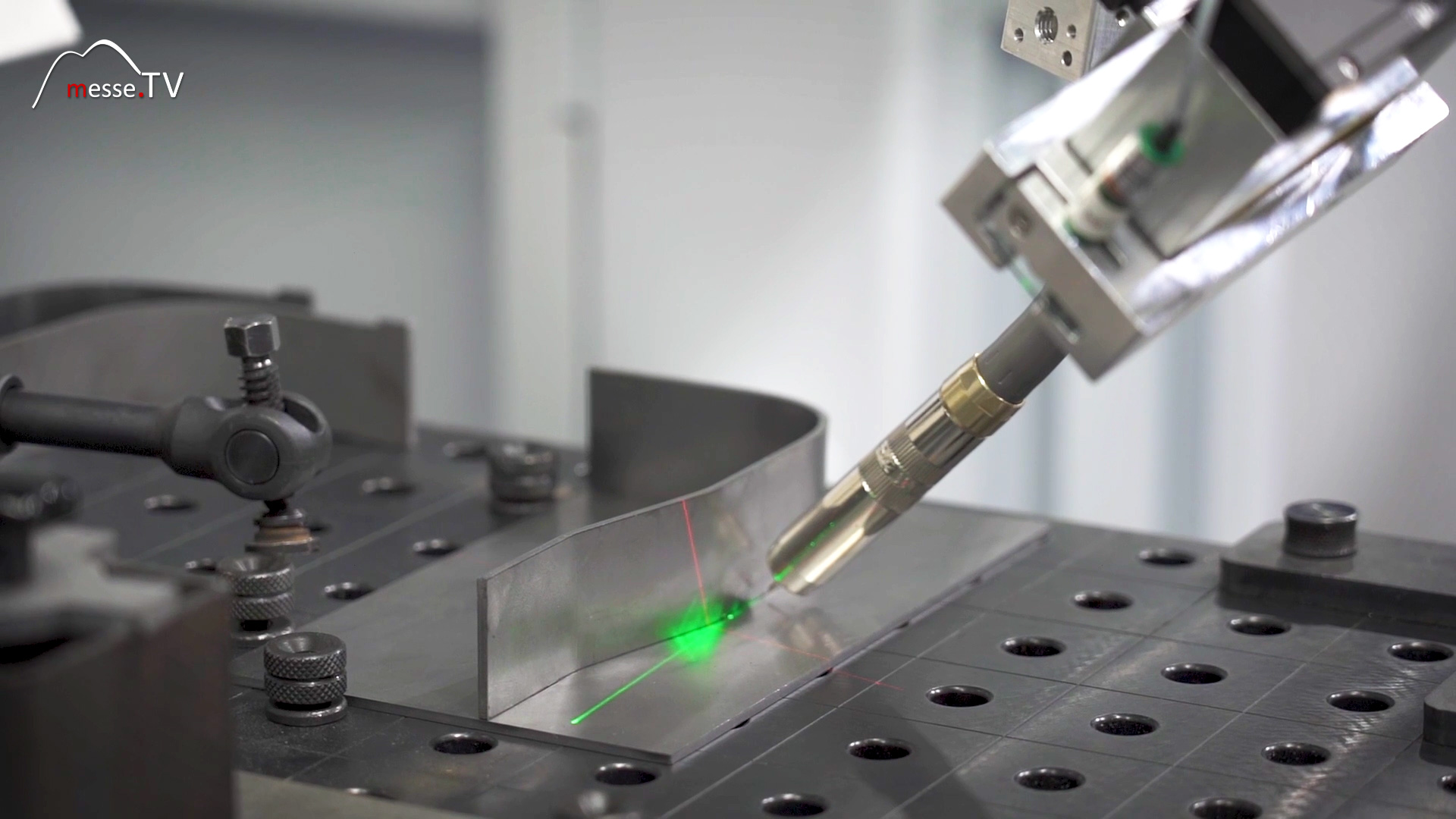

The seam tracking sensor plays a central role in the welding process. Instead of manually programming the entire seam path of a component in detail, the operator only has to define the start and end points of the weld seam. Based on this, the system automatically detects the actual seam position. Deviations due to manufacturing tolerances, component misalignment, or slight inaccuracies are automatically compensated for. This significantly reduces the number of programming steps required. Programming becomes easier, faster, and less prone to errors, without compromising the quality of the weld seam. This approach is particularly advantageous for companies with frequently changing components or small batch sizes. New components can be integrated into production with significantly less effort, which increases responsiveness to customer inquiries.

The Trumpf TruArc Weld uses arc welding, which is used in many industrial applications. This process is powerful and versatile, but places high demands on process control and the experience of the operating personnel. In conventional systems, precise programming is essential to achieve uniform weld seams. Automatic seam tracking significantly reduces these requirements. The arc follows the actual seam, not a rigidly programmed path. This keeps the process stable, even if components are not positioned exactly identically. The arc process thus becomes more controllable and less dependent on individual experience.

A typical application example is the welding of a simple flange. With conventional systems, the entire seam path must be precisely programmed, which requires several steps. With TruArc Weld, it is sufficient to define the relevant corner points. The seam tracking sensor automatically detects the path and executes the welding process accordingly. This principle can also be applied to other components where the geometry is clearly defined but the position may vary. The system is therefore suitable for both simple and varied applications in series production.

A key topic in customer discussions for years has been the shortage of skilled workers in welding technology. Qualified welders are hard to find, and this situation has worsened during the coronavirus pandemic. Many companies have had significantly fewer skilled workers available at times, partly because workers from abroad were no longer able to enter the country. The TruArc Weld was launched during this phase and met a specific need. The aim is not to replace or reduce the number of skilled workers. Rather, it is to create flexibility in production and relieve the burden on existing staff. Recurring or less complex welding tasks can be automated, while qualified welders can concentrate on more demanding tasks.

TruArc Weld is designed to complement existing manufacturing structures in a meaningful way. It can be integrated into existing production lines and helps to reduce bottlenecks in the welding shop. By automating repetitive tasks, production capacities can be increased without the need for extensive restructuring. The system thus represents an approach to welding technology in which automation is used in a targeted manner to make processes more stable, simpler, and more flexible. The seam tracking sensor forms the technical core, combining precision and usability and ensuring long-term production reliability.