The TNA brush deburring machine is designed for industrial series processes in which metal components must be processed with a high degree of repeat accuracy. It is part of a machine portfolio that includes grinding and deburring systems for various industrial applications.

The system was developed by Weber Maschinenbau, a family-run company from Upper Franconia that has been active in mechanical engineering for several generations. The focus is on stable processes that can be permanently integrated into automated production environments. In many industrial sectors, components are initially produced by pressing, punching, or fine cutting. These processes are productive, but inevitably result in burrs and sharp edges. To remove these, grinding and deburring systems are used, which must be precisely matched to the material, geometry, and quantity. Within this spectrum, the TNA brush deburring machine is a specialized solution for mass-produced metal components where uniform edge processing is crucial.

Grinding and deburring systems play a central role in industrial manufacturing. They ensure that components can be further processed in a functional, safe, and assembly-ready manner after the forming process. The TNA brush deburring machine is designed for precisely this step. It is used where large quantities have to be processed with reproducible quality and manual reworking is not economically viable. Typical areas of application are found in the series production of functional parts where tight tolerances must be maintained.

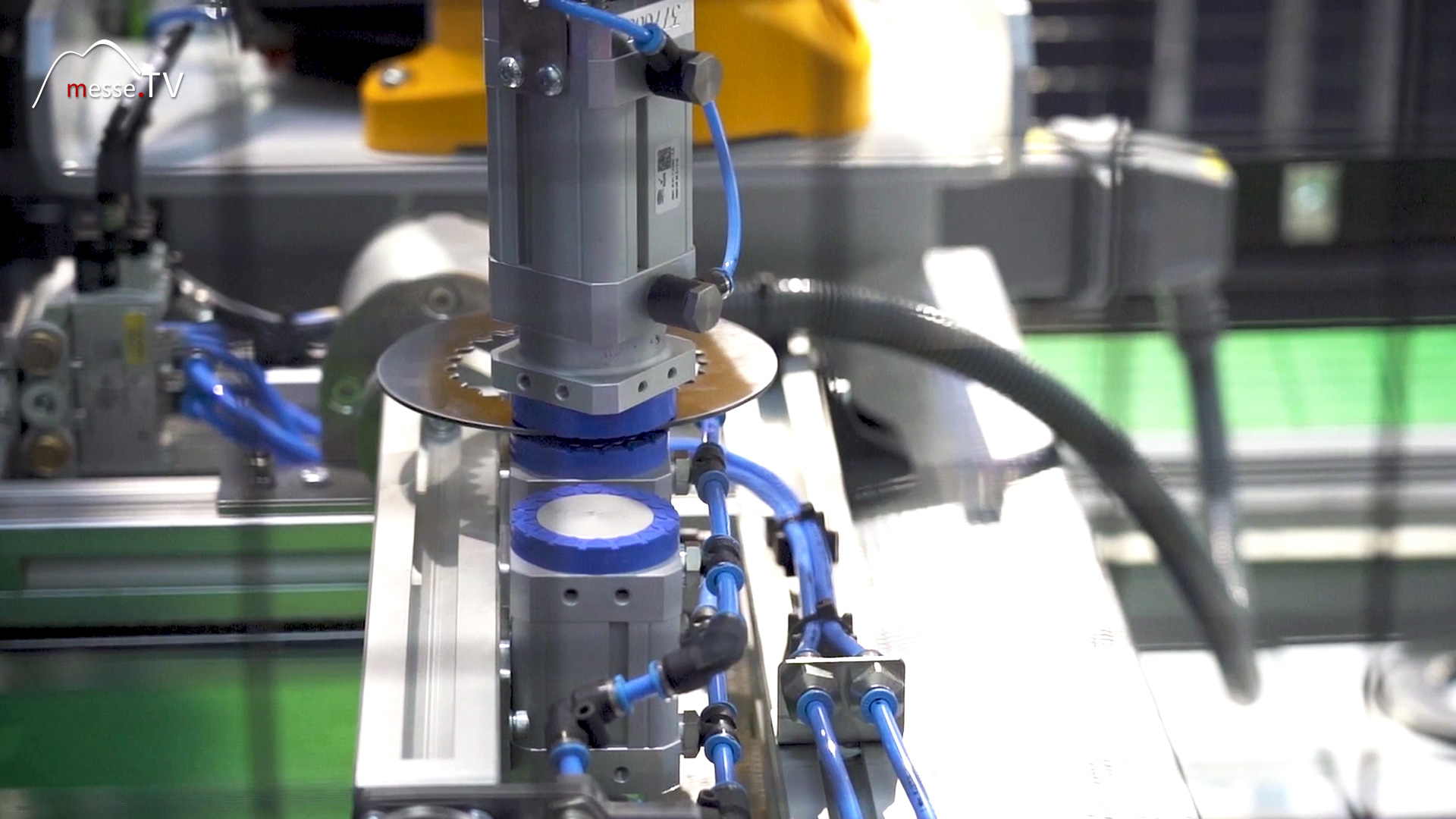

The TNA's processing concept is based on a clearly structured sequence. The parts are fed automatically and first brushed on one side. An integrated robotics system then returns the workpieces to a parts turner. This turns the components so that the second side can also be processed. Despite the brush unit working on one side only, both sides can be deburred within a closed process. This solution is typical for modern grinding and deburring systems, where efficiency and process reliability are paramount.

For automated series production, the integration of the system into existing production lines is crucial. The TNA brush deburring machine can be connected directly to upstream presses or punching machines. It can also be combined with downstream handling systems, palletizing systems, or mesh box filling systems. Loading and unloading processes are interlinked to ensure a consistent flow of material. The system thus meets a typical requirement of modern grinding and deburring systems, namely seamless integration into continuous manufacturing processes.

The TNA brush deburring machine is primarily used for components such as those found in the automotive industry and related industries. These include clutch discs, springs, parking locks, gear wheels, and similar functional parts. These components are often produced in very large quantities and place high demands on edge quality. Grinding and deburring systems must work reliably here to avoid rejects and ensure the functionality of the parts.

An important part of the concept is the accompanying process development. Weber Maschinenbau does not supply the TNA brush deburring machine as an isolated standard machine, but supports users in designing the machining process even before commissioning. This includes selecting suitable brushes, setting parameters, and defining processing speeds. This preparatory work is particularly crucial in the field of grinding and deburring systems, as component geometries and materials can vary greatly.

The system is developed and manufactured with a high degree of vertical integration. Key mechanical components are manufactured in-house, enabling close coordination between design, assembly, and commissioning. The mechanical design is complemented by control and software systems that allow integration into higher-level production environments. Process data can be recorded and evaluated to further stabilize and optimize processes. Typical features of the TNA brushing and deburring machine in the context of grinding and deburring systems are:

The TNA brush deburring machine is an example of a mechanical engineering approach in which grinding and deburring systems are not regarded as individual machines, but as part of a complete production process. The combination of deburring technology, automation, and process knowledge enables solutions that can be used in series production over the long term. For users, this means a stable system that delivers reproducible results and can be integrated economically into existing production structures.