Rea Elektronik is based near Darmstadt and specializes in industrial marking. This refers to the contactless marking of products and materials in demanding industrial environments. This expertise will be showcased at the trade fair, because marking systems must function reliably in harsh environments. Printing on steel, aluminum, and other resistant surfaces is one of the areas of application in which the company is a market leader.

Around 400 employees work on the development and manufacture of several product lines at the Mühltal site. The portfolio comprises a total of eight different lines, some of which have been specifically developed for the steel and sheet metal processing industry. These systems are designed to deliver reproducible results even under harsh conditions and to integrate seamlessly into existing production processes.

In this context, industrial marking means much more than simply applying information. In steel and sheet metal processing, markings must be permanently legible, even when components are exposed to high mechanical stress, heat, or contamination. This is precisely where non-contact methods come into play, as they work without direct contact with the workpiece, thus avoiding wear and damage. The systems are designed to adapt flexibly to different surfaces and materials. Whether smooth steel, coated aluminum, or textured surfaces—the marking remains precise and reliable. This robustness is a key reason why the solutions are used in heavy industry in particular.

Some of the systems developed are specifically designed for applications in steel and sheet metal processing. Process reliability and traceability play a major role here. Markings are used not only for identification, but also for quality assurance and documentation within complex production chains. The systems can be integrated into existing production lines and support a variety of information content, from simple codes to complex patterns. This creates a continuous link between manufacturing, logistics, and quality management.

A cooperation with LBI will also be presented at the trade fair. The aim of this partnership is to combine high-performance lubricants with modern technology. The focus is on applying lubricants exactly where they are needed and, at the same time, making this process digitally controllable. Precise placement ensures that only the amount actually needed is used. This reduces material consumption and costs. At the same time, it creates seamless traceability, which enables an exact analysis of the unit costs per component.

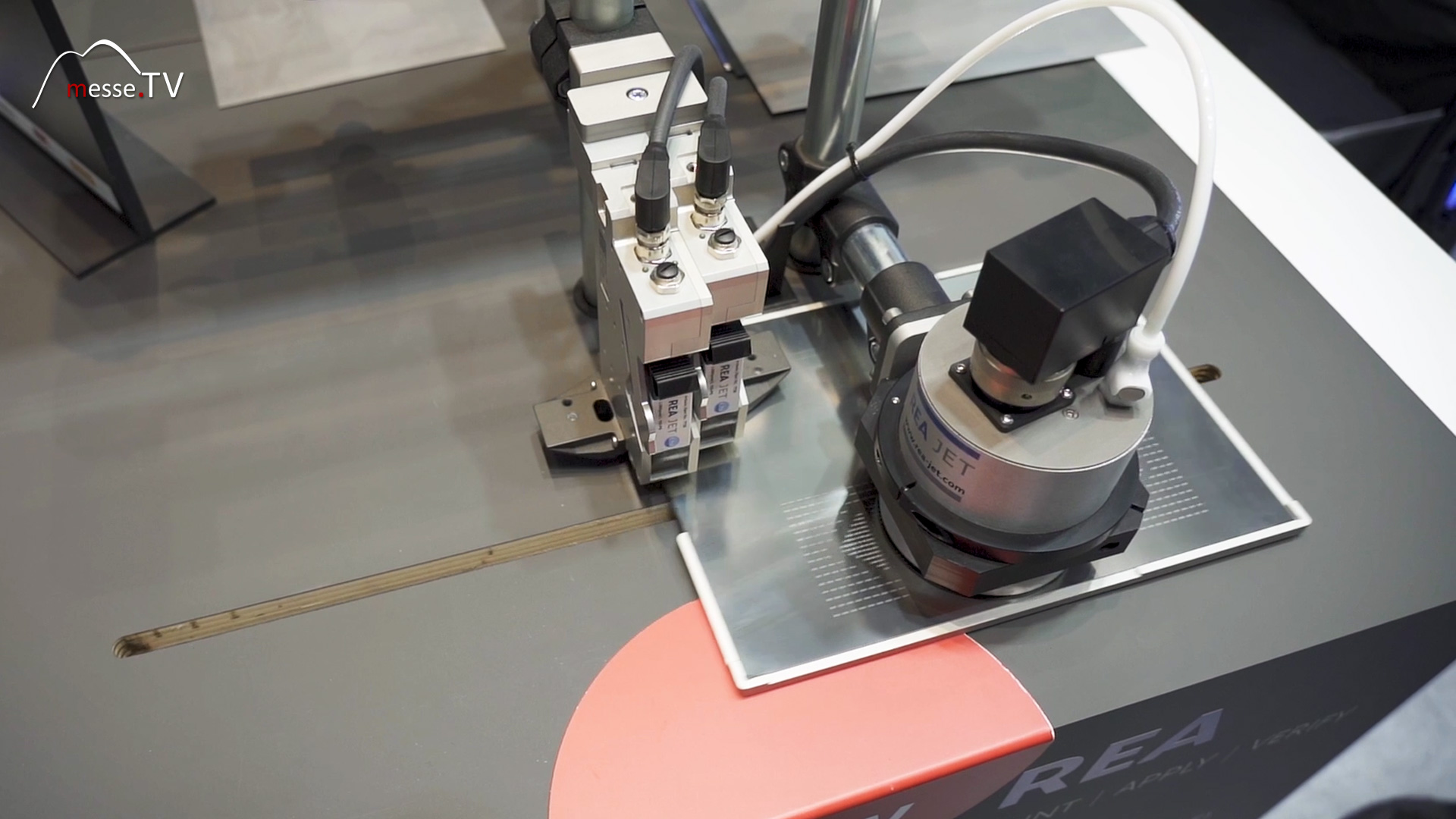

Two different technical approaches are used. A high-resolution system is suitable for fine applications, while a so-called drop-on-demand system is designed for applications with lower resolution. The latter allows larger quantities of lubricant to be applied in a targeted manner. Both variants are fully digitally controllable and can be precisely tailored to the respective process. The systems work with different control units. In addition to a classic version, a modern version with a touchscreen is also available. Regardless of the control unit used, all print heads can be operated, which increases flexibility in application.

The lubricant is fed directly from a cartridge into the print head. There, micro nozzles of various sizes ensure that the lubricant is dispensed precisely. Up to two thousand drops are ejected per second. Despite this high frequency, neither mist nor aerosol is produced. Extraction is therefore not necessary, which significantly simplifies use in existing production environments. The operating principle is reminiscent of familiar printing technologies from the office sector. Similar to an ink cartridge, the lubricant is applied in a targeted manner, but under industrial conditions and with significantly higher requirements for reliability and repeatability.

The combination of industrial marking and precise lubricant application opens up new possibilities for steel and sheet metal processing. Processes become more transparent, efficient, and easier to control.

The innovations presented won second place in the punching technology category. This award recognizes the technical development of the past two years and confirms that we are on the right track. The response at the trade fair also shows that the concept is meeting with great interest. Visitors recognize the practical benefits of the systems and see them as a relevant contribution to the optimization of industrial processes. The combination of industrial marking and controlled lubricant application illustrates how digital technologies can complement traditional manufacturing steps. This opens up new opportunities for combining quality, efficiency, and transparency, particularly in steel and sheet metal processing.