Inspecvision is a company based in Northern Ireland that specializes in 2D and 3D measurement technology. Its technological focus is on the precise measurement of components produced in industrial manufacturing.

The focus is on applications in sheet metal processing, but also on more complex tasks involving the inspection of bent or welded assemblies. The aim is to detect geometric deviations at an early stage and to integrate measurement processes into everyday production as efficiently as possible.

The measurement technology covers two central fields of application. On the one hand, it deals with classic two-dimensional components, as frequently found in sheet metal processing. Here, contour accuracy, dimensional accuracy, and repeatability play a decisive role. On the other hand, three-dimensional components are measured, such as bent parts or welded assemblies, where heights, angles, and spatial curves must be checked. The special feature is that both worlds – 2D and 3D – are not considered separately, but can be combined within a single system. This makes the solution ideal for manufacturing environments in which different component geometries have to be checked without constantly switching between different measuring systems.

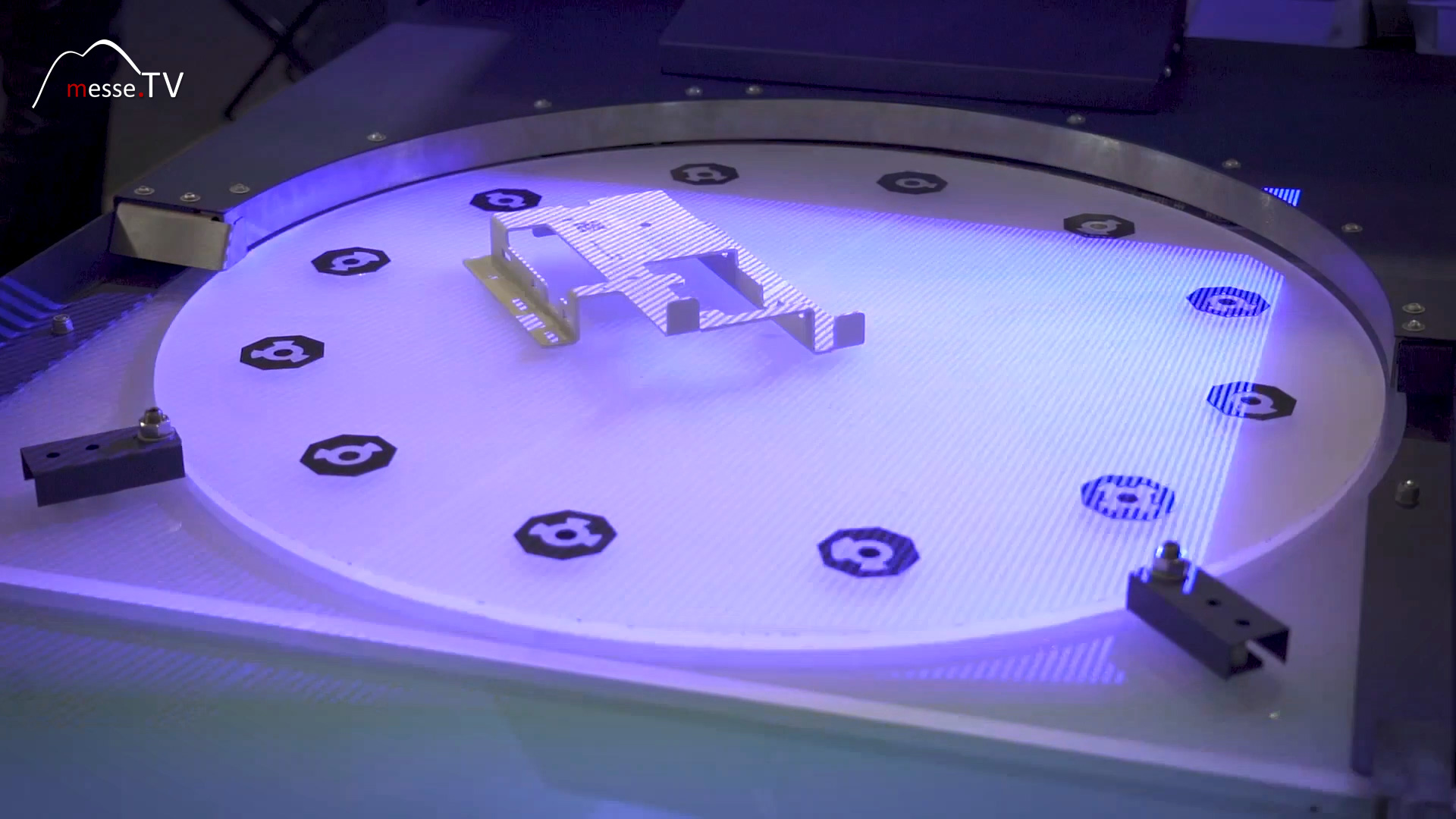

The highlight of the trade fair is a combination system that enables both 2D and 3D measurements. This system is designed in such a way that it can be flexibly adapted to the respective measurement task. A rotary table is available for measuring 3D components, which is used in combination with a scanner. The component is rotated so that all relevant areas can be captured. Once the three-dimensional measurement is complete, the rotary table can be moved backwards. This frees up the entire measuring surface for two-dimensional components. This changeover does not require any complex modifications and allows you to switch between 3D and 2D applications within a short time. This concept offers a clear advantage, especially in production environments with changing product variants.

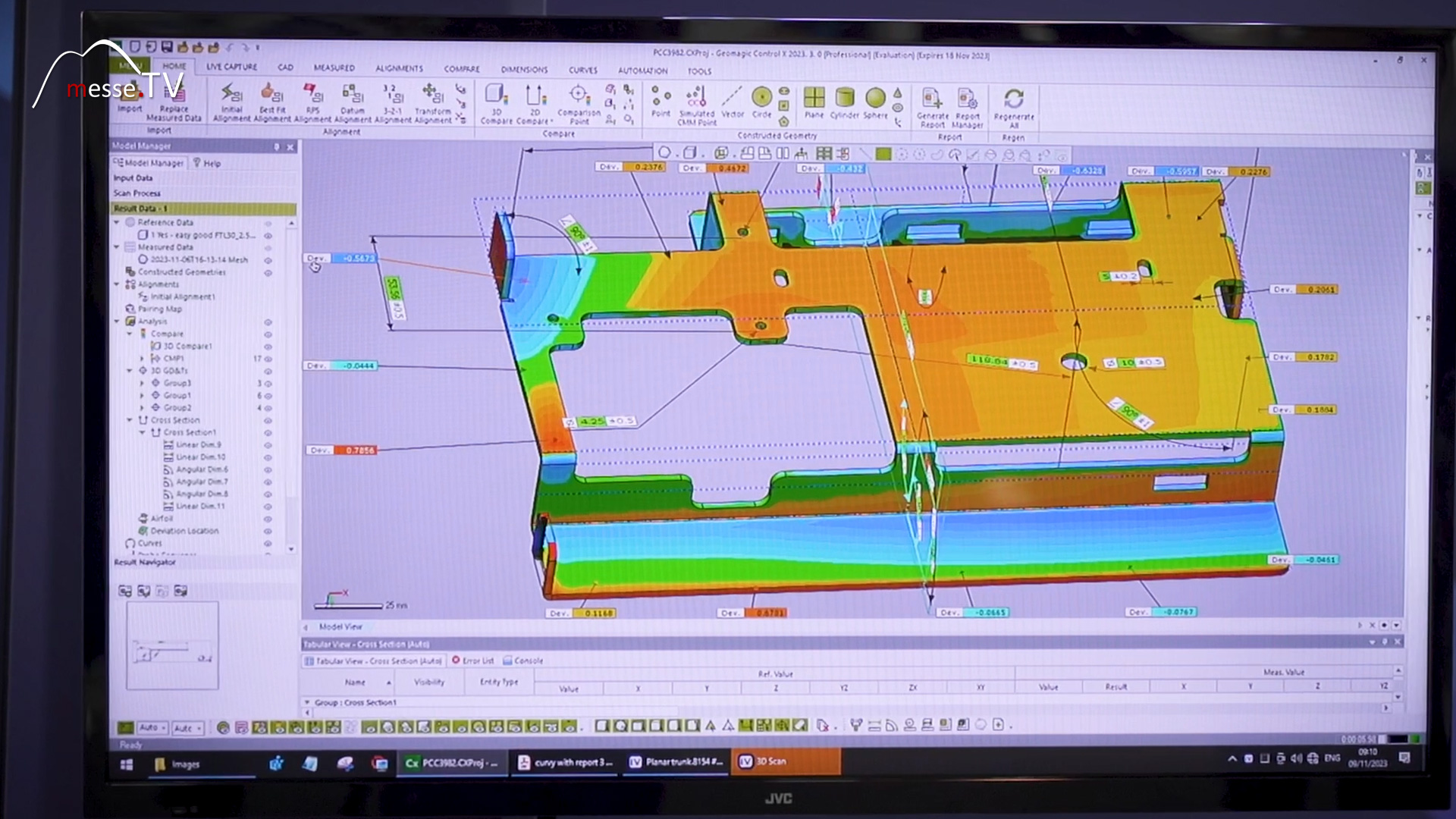

2D measurement is based on an optical principle. The components are positioned on a glass surface. LED lights are located below this surface, illuminating the component evenly. A camera is installed above the surface, capturing high-resolution images. As soon as the lighting is activated, the camera captures the contours of the component. The software converts these contours into measurement data. The captured geometries can then be compared directly with a 2D CAD contour. Deviations are immediately visible, allowing dimensional errors or shape deviations to be clearly identified. This direct comparison greatly facilitates quality control and reduces the effort required for manual rechecking.

For three-dimensional components, the rotary table is used in combination with a scanner. While the component rotates, the scanner continuously captures the surface. This creates a complete three-dimensional image that is used for evaluation. This method is particularly suitable for curved parts or welded assemblies where simple 2D measurements are not sufficient. Even complex geometries can be completely captured in this way. The data obtained provides a detailed basis for assessing dimensional accuracy and shape accuracy.

The software is a central component of the system. It not only evaluates the measurement data, but also converts images into usable geometries. Contours are automatically recognized, measurement points calculated, and deviations visualized. This results in a continuous measurement process from data acquisition to evaluation. The software is continuously being further developed. The aim is to integrate new functions and further simplify existing processes. Improvements relate to both the user interface and the automation of processes.

A central topic is the automation of the measurement process. The aim is to minimize manual intervention by operators. Ideally, the system will perform the entire measurement independently, from acquisition to evaluation. This reduces operating errors, saves time, and increases the reproducibility of results. This approach is particularly crucial in series production. Automated measurement processes can be integrated directly into production lines and enable continuous quality monitoring. This makes measurement technology an integral part of production rather than a downstream control step.

The combination of 2D and 3D measurement opens up a wide range of possible applications:

The measurement technology presented here shows how optical methods are increasingly supplementing or replacing traditional tactile measurement methods. The combination of camera, lighting, scanner, and software creates flexible systems that can be adapted to different requirements. This approach offers clear advantages, especially in industries with a high degree of variety and short product life cycles. The trend toward more automated measurement processes also illustrates that measurement technology is becoming increasingly intertwined with production. Quality assurance is no longer carried out in isolation, but as an integrated part of the manufacturing process. This is exactly where combined 2D and 3D measurement technology comes in, creating the basis for precise, efficient, and traceable quality control.