Schuler is one of the most traditional companies in industrial mechanical engineering in Germany. Founded in Göppingen in 1839, the company has been closely associated with the development of metal forming technology for more than 180 years. The focus is on presses for the automotive industry and its suppliers, although the range of applications has expanded significantly over time. Today, these systems are used to produce not only classic car body components, but also a wide range of industrial products that go far beyond vehicle construction.

In the automotive sector, presses are used to manufacture hoods, doors, and load-bearing structural components. These components must meet high requirements in terms of dimensional accuracy, surface quality, and process reliability. At the same time, the systems are also used for less obvious applications. Furniture fittings, coins, electrical sheets for motors, and cell housings for batteries are also manufactured using modern forming technology. The range shows how versatile press technology is today.

The presses are designed for high volumes and stable series processes. This has been standard practice in the automotive industry for decades, but is also gaining importance in new branches of industry. The change in drive technologies is giving rise to new requirements, for example in the manufacture of battery housings or electrical steel sheets for electric motors. These components must be manufactured with precision and place special demands on material processing and process control. In addition to electromobility, other industrial sectors also play a role. Technical functional parts, coin minting, and fittings for furniture are also manufactured on presses. Forming technology thus remains a key technology that is used in a wide variety of markets and can adapt to new requirements.

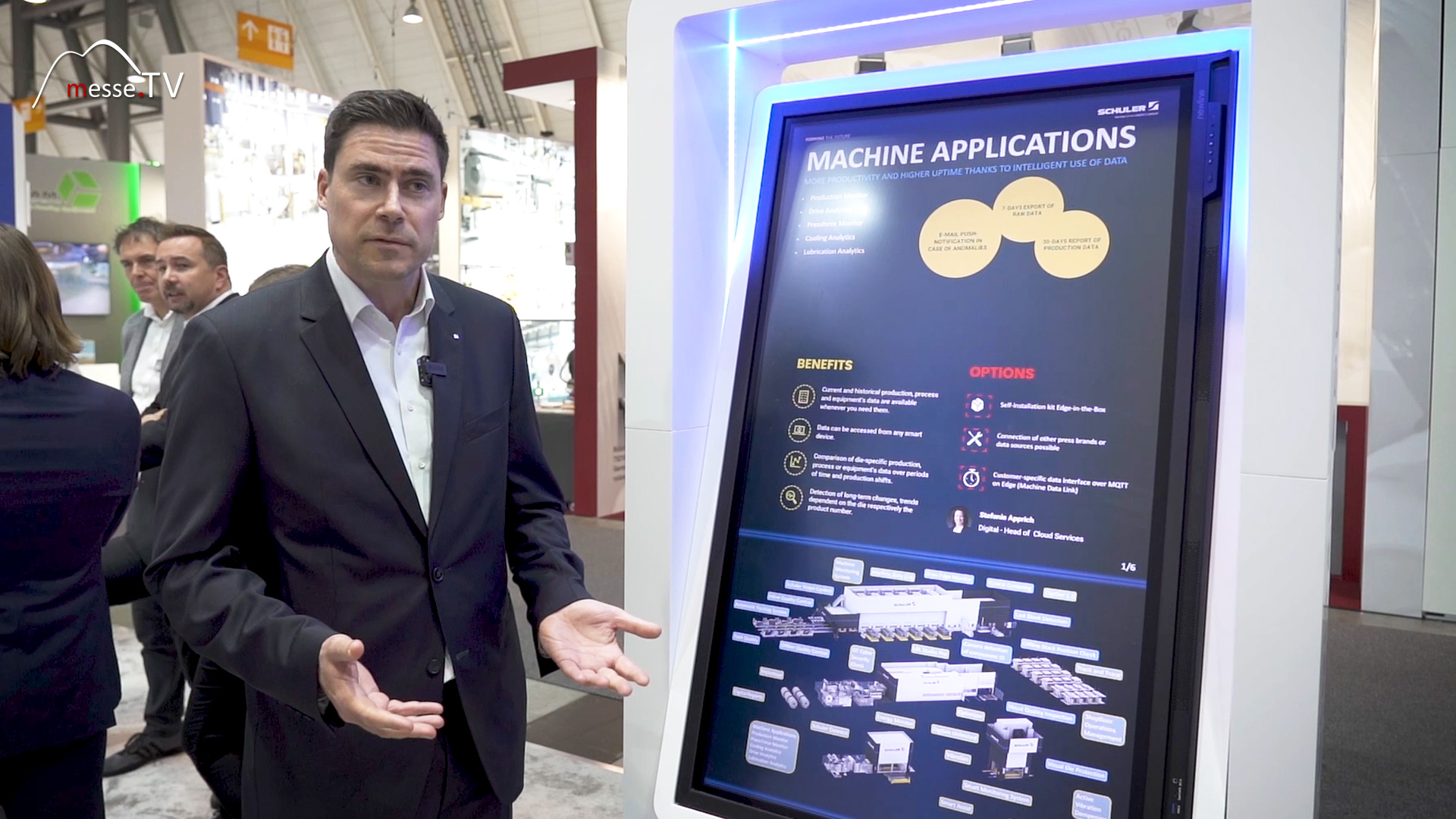

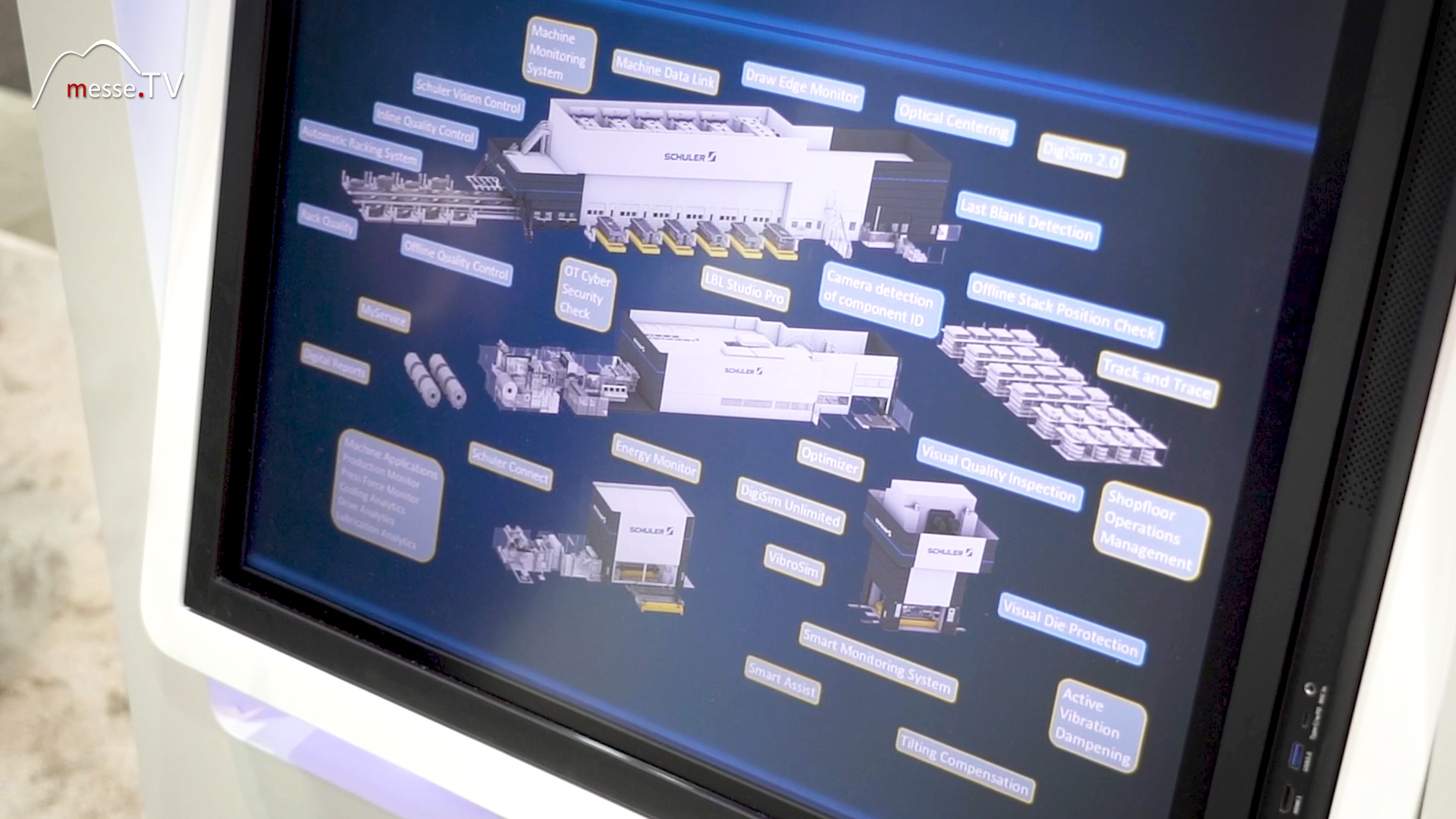

For a long time, the company was known exclusively for its machines and systems. Now, the development of software solutions is an integral part of its range of services. Digital applications for forming technology are bundled under the so-called Digital Suite. The aim is not only to make machines mechanically efficient, but also to operate them more intelligently and safely through digital systems. Entering the field of software development was a significant step for a traditional machine manufacturer. The first digital solutions were launched on the market back in 2016. Many of these systems are now an integral part of real production environments and help users to monitor, analyze, and optimize processes. Digitalization thus complements existing press technology without replacing it.

A central component of digital solutions is machine vision. These are camera-based systems for monitoring tools and components. One example is visual quality inspection, which visually inspects components immediately after the forming process. This allows errors or deviations to be detected at an early stage before they affect downstream processes. Another important system is visual die protection. This solution monitors the tool during operation. If the system detects foreign objects, misalignments, or other malfunctions, it automatically stops the press. This intervention is faster than an operator could achieve and protects tools and equipment from damage. Such systems contribute significantly to reducing downtime and increasing process reliability.

Digital applications are not intended as theoretical concepts, but are used in real production environments. One example of this is the Smart Press Shop in Halle, Saxony-Anhalt, a joint project with Porsche. Numerous digital solutions are used there during ongoing operations. They demonstrate how press technology, software, and process data can be meaningfully combined. For the company, this development meant a significant expansion of its own competence profile. In addition to mechanical design and plant engineering, software development, data processing, and system integration are now also integral parts of the work. This change was necessary in order to meet the increasing demands of modern production facilities.

Current developments can be attributed to two major industrial transformations. The first is digital transformation. Production processes are increasingly networked, monitored, and controlled on the basis of data. Digital solutions help to ensure quality, avoid downtime, and continuously improve processes. The second transformation concerns the shift toward greater sustainability. Electromobility is a key issue, as are alternative drive concepts. Presses and systems for manufacturing battery housings, electric motors, or complete battery production lines are now part of the product range. In addition, solutions are also being developed for the production of fuel cells, which are relevant for hydrogen propulsion. These developments show that forming technology plays a central role in the industrial implementation of new technologies. Without high-performance presses and stable processes, neither electromobility nor hydrogen propulsion can be transferred to series production.

Schuler is a prime example of the transformation in industrial mechanical engineering. A traditional manufacturer of presses has become a supplier that combines mechanical engineering, digital systems, and process knowledge. The combination of decades of experience in forming technology and new digital and sustainable approaches shows how industrial companies can evolve without losing their technological base. Industrial change does not happen abruptly, but builds on existing technologies. Presses remain at the heart of manufacturing, but are complemented by software, optical systems, and new applications. It is precisely this combination that provides added value for users who need to future-proof their production.