The Schmalz company has its origins in the Black Forest and can look back on more than a century of history. Over more than a century, the company has developed from a regional manufacturer to an internationally active provider of solutions for industrial handling.

Today, around 1,800 employees work in approximately 30 countries, with subsidiaries on several continents. Production continues in the Black Forest, but also in countries such as China, India, the USA, Australia, and Poland. This international presence is closely linked to the requirements of global industrial companies.

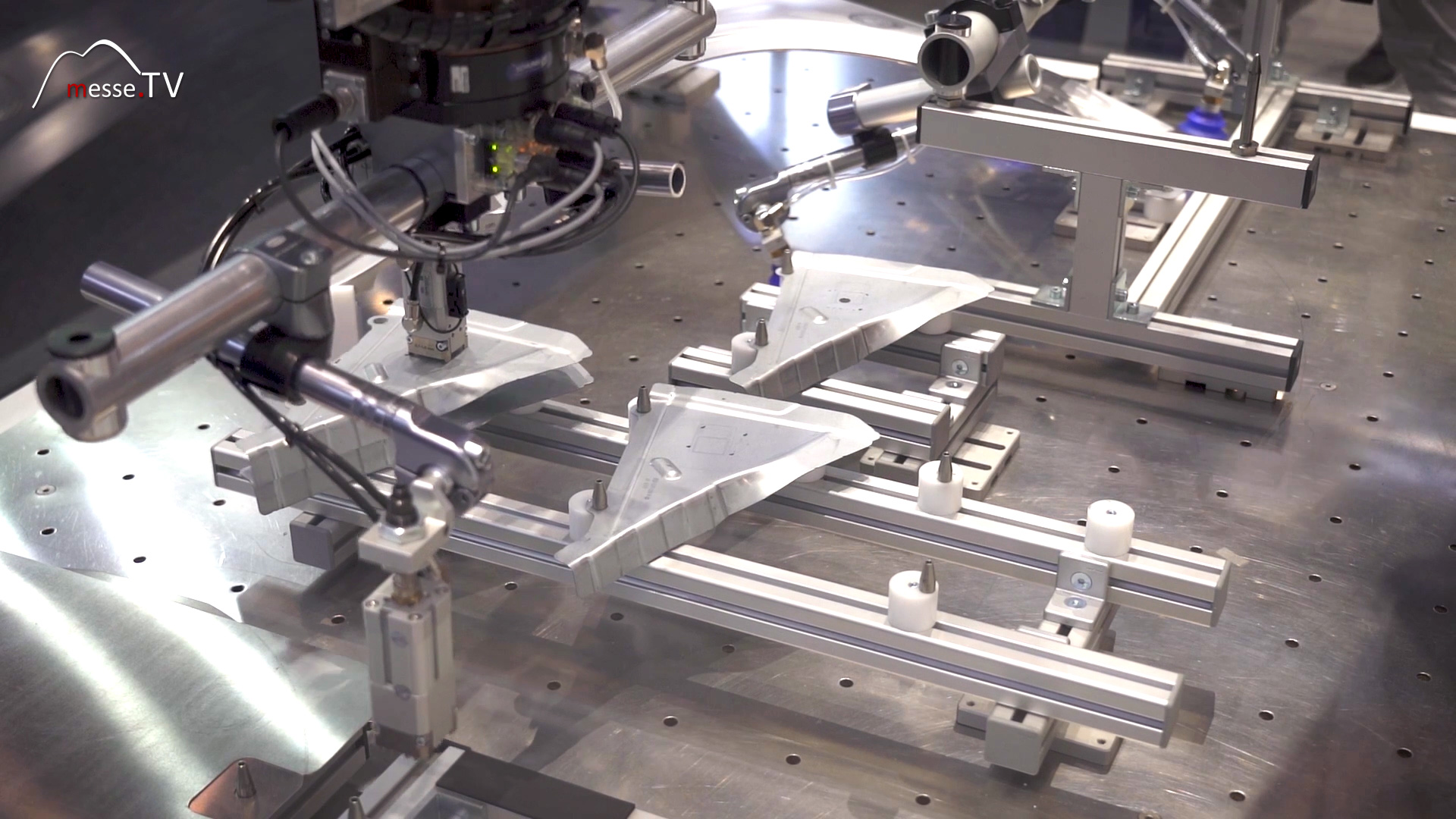

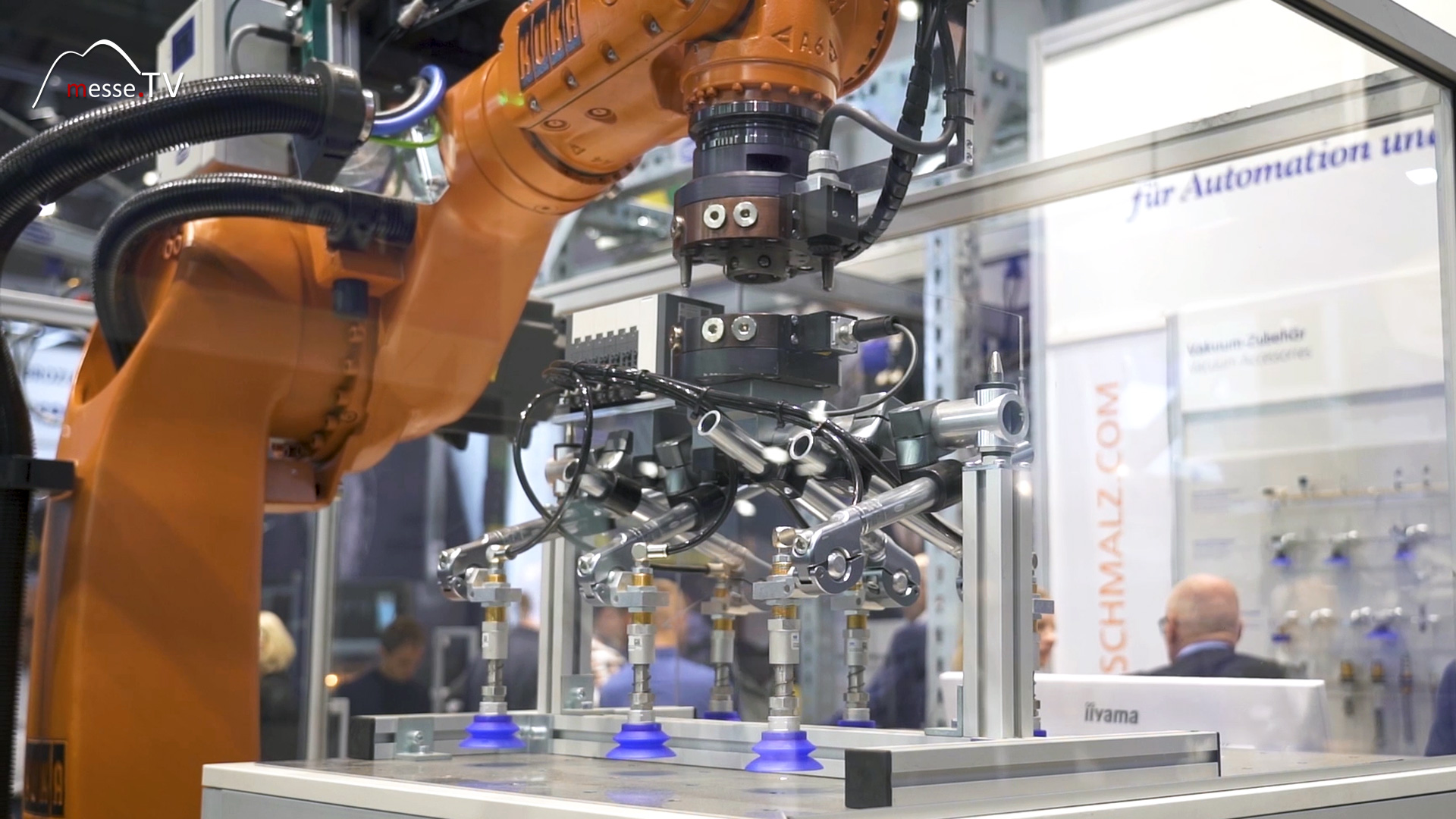

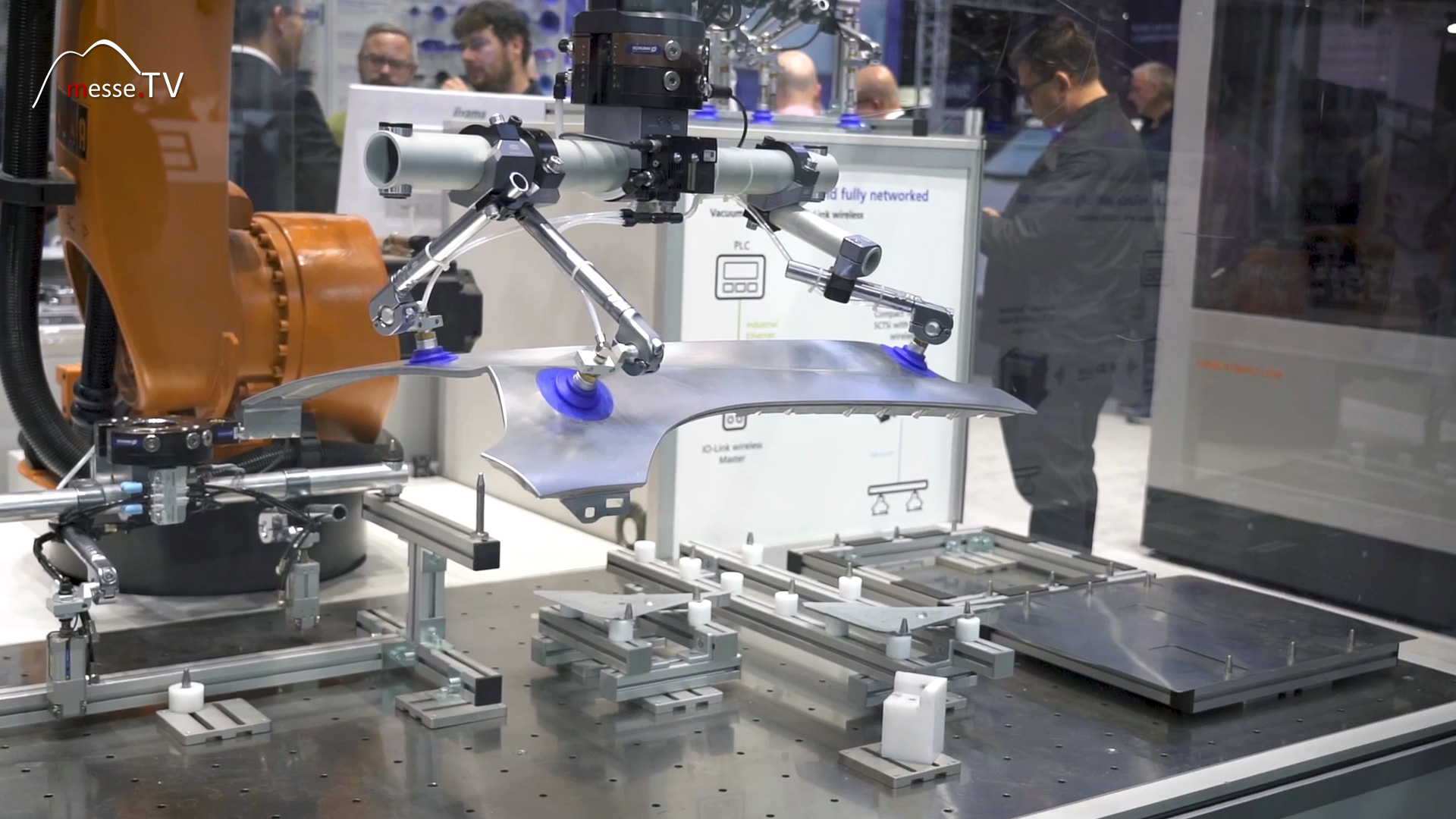

At the core of the portfolio are vacuum components and complete systems for industrial automation. These solutions are primarily used where robots or automated systems need to grip, move, and position workpieces. Typical applications include the handling of sheet metal, but also furniture parts or plastic components. The range of workpieces extends from thin-walled components to large-area or sensitive components. These systems are supplemented by handling devices that are specially designed to meet ergonomic requirements. They support employees in moving heavy or unwieldy workpieces safely. The aim is to reduce physical strain while increasing productivity in production. These solutions therefore address not only efficiency, but also occupational safety and ergonomics.

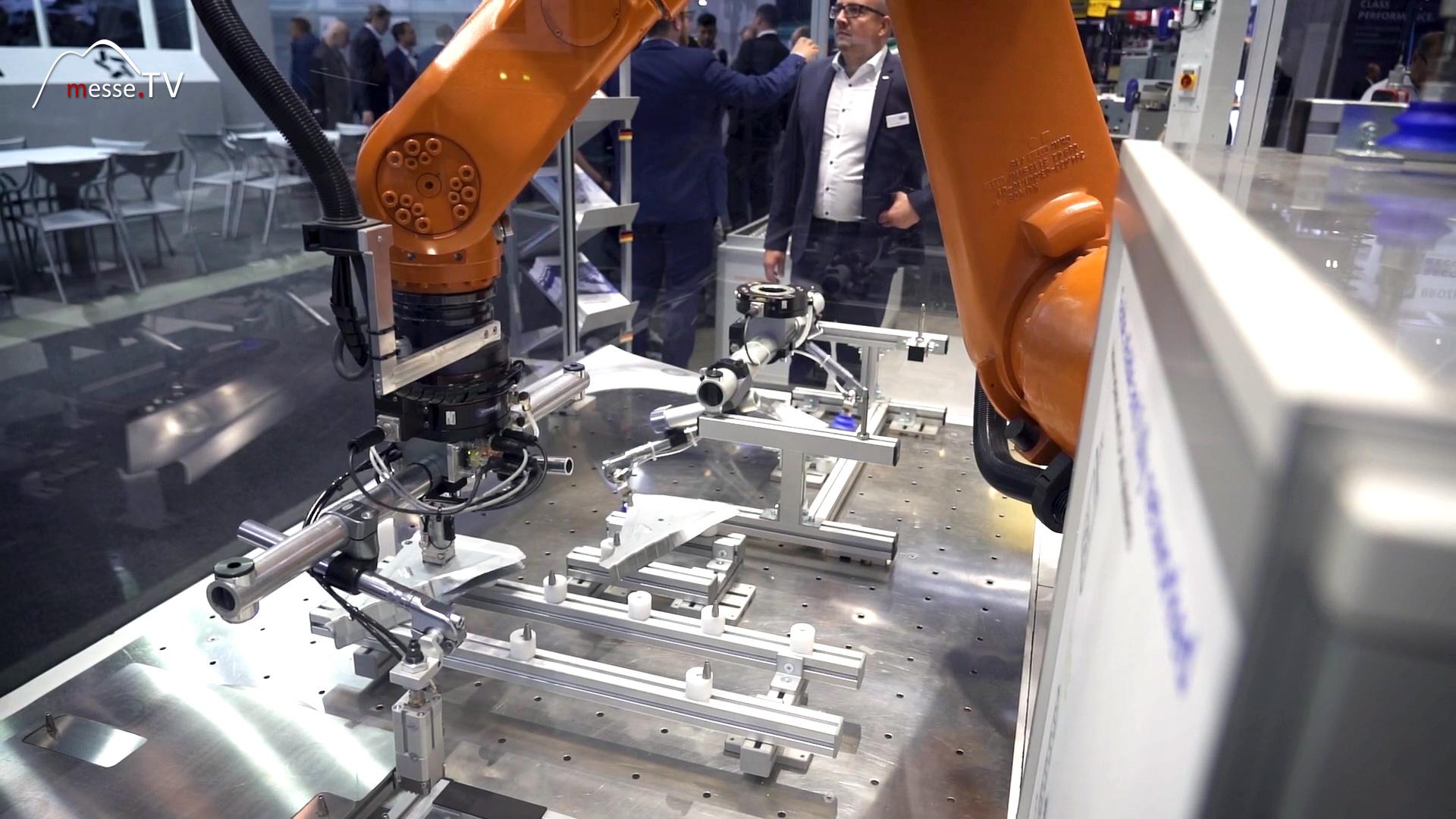

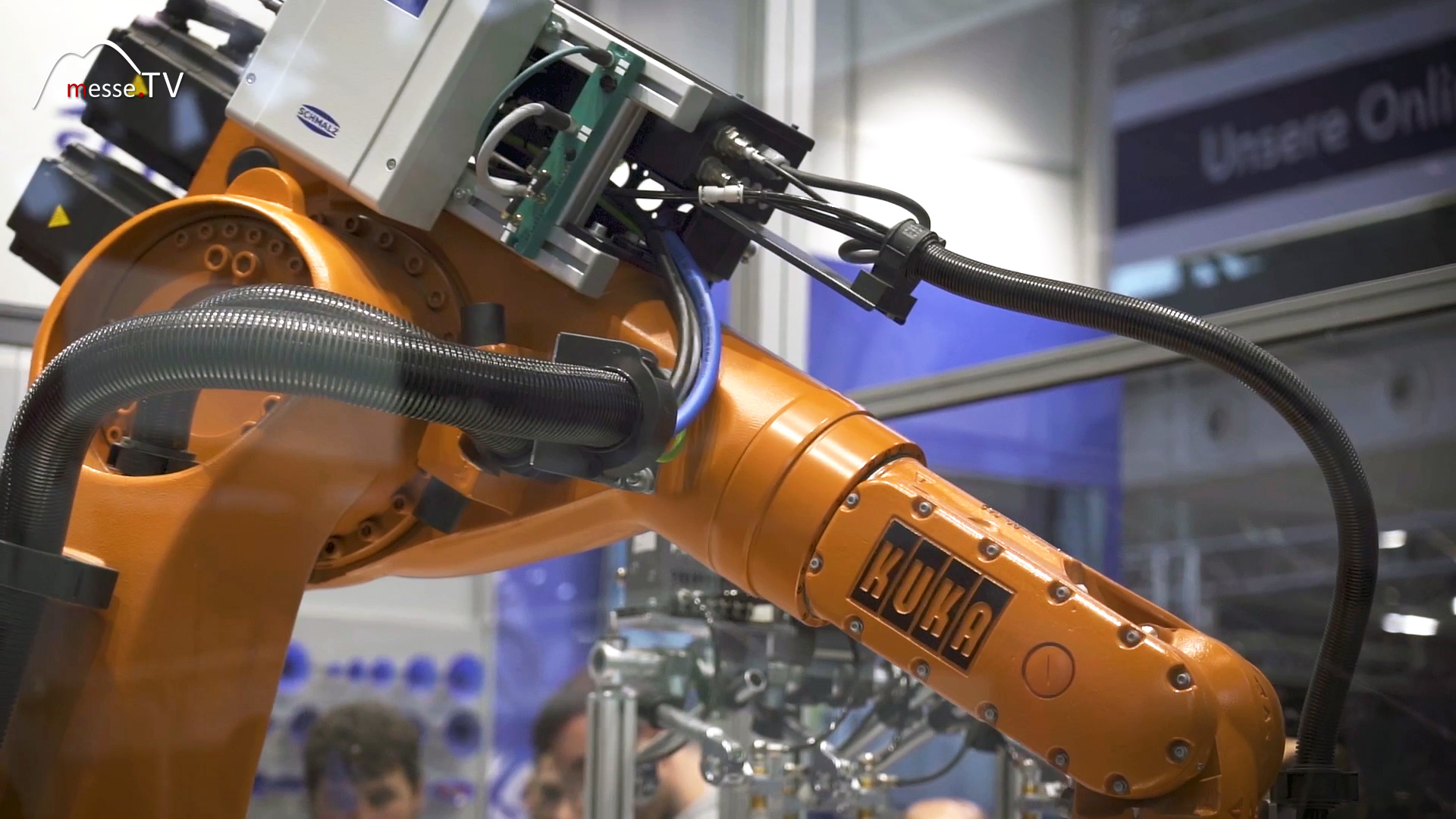

An important area of application is the automotive industry. Here, vacuum and gripping systems are used to handle car body parts or other large-format components. Several factors play a central role in this environment: speed, energy efficiency, and process reliability. The systems are designed to enable short cycle times while optimizing energy consumption. One technical focus is on wireless communication between the vacuum generator, sensors, and the higher-level control system. This wireless connection simplifies integration into existing systems and reduces installation costs. At the same time, process data can be recorded and evaluated, which increases transparency in production.

As a supplier of gripping tools for automation, the company is intensively involved in the field of picking. This involves the targeted gripping and handling of sheet metal workpieces, such as those found in press shops or car body shops. This field is currently gaining in importance as production lines need to become more flexible and components are not always available in exactly the same position. In this context, so-called bundles are offered that combine gripping systems with cameras and software. Visual detection of the components makes it possible to recognize their position and orientation and adjust the gripping process accordingly. This allows even disordered or varying workpiece positions to be handled automatically, which significantly increases the flexibility of production lines.

International orientation is a central component of the corporate strategy. One of the two clearly defined strategic directions is the presence in China. A new headquarters was opened there in order to be closer to the market and the competition. The aim is to identify developments on site at an early stage and to adapt products specifically to regional requirements. The second strategic direction is innovation. A high level of research and development expenditure is intended to ensure that new and improved products are continuously created. This is not only about technical developments, but also about economic aspects. Innovative solutions should create a competitive advantage while remaining efficient to produce.

A key issue is the cost side. The bureaucratic burden and high costs in Germany are described as a major challenge. These conditions make it difficult to remain competitive, especially in international comparison. As a consequence, production capacities are being relocated to countries where conditions are more favorable, such as China. At the same time, local production is taking place there in order to shorten transport routes and be closer to customers.

Clear expectations are being formulated with a view to the future. These include a noticeable reduction in bureaucracy to give companies more room for maneuver. There is also a call for a sustainable model for energy costs that secures industrial production in the long term. Another focus is education. The promotion of training and young engineers, especially in STEM professions, is seen as crucial. This support must begin early, already in school, and continue through college. Infrastructure also plays an important role. The condition of roads, networks, and especially digital connectivity is viewed critically. A stable internet and mobile phone connection is considered a basic requirement for modern industry, especially in rural regions such as the Black Forest.