Jenoptik has been active in the field of photonics for many years and covers a broad technological spectrum. This includes lasers, optics, optical circuits, image processing, and camera technology. At the trade fair, however, the focus is on a very specific application: 100% inspection of stamped parts in contact manufacturing – directly during ongoing production at full stroke speed. It is precisely this requirement that forms the basis for the solution on display and also explains why the company received an award for this development.

Enormous quantities are produced in the industrial manufacture of contact parts. The components are produced by the ton, often in continuous punching processes. Even the smallest dimensional deviations or defects can have a significant impact, for example on electrical function or further processing. Classic random sampling is not sufficient here. What is required is a complete inspection of all parts without interrupting the production flow.

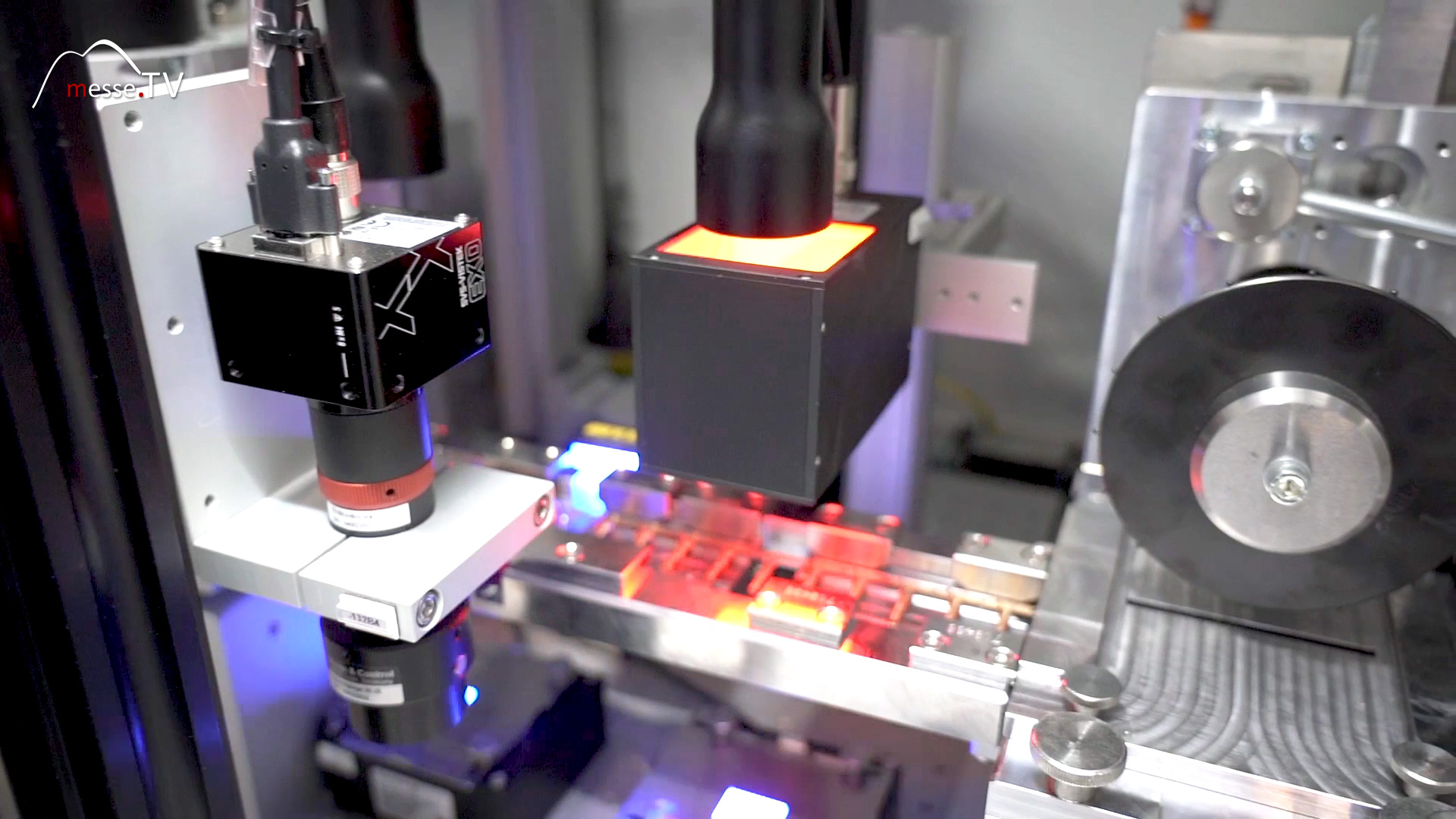

Photonics systems make this possible. The combination of high-resolution image processing, precise lighting, and powerful evaluation allows defects, dimensional errors, and deviations to be detected in real time. What makes this special is that this inspection is integrated directly into the ongoing process and does not take place downstream.

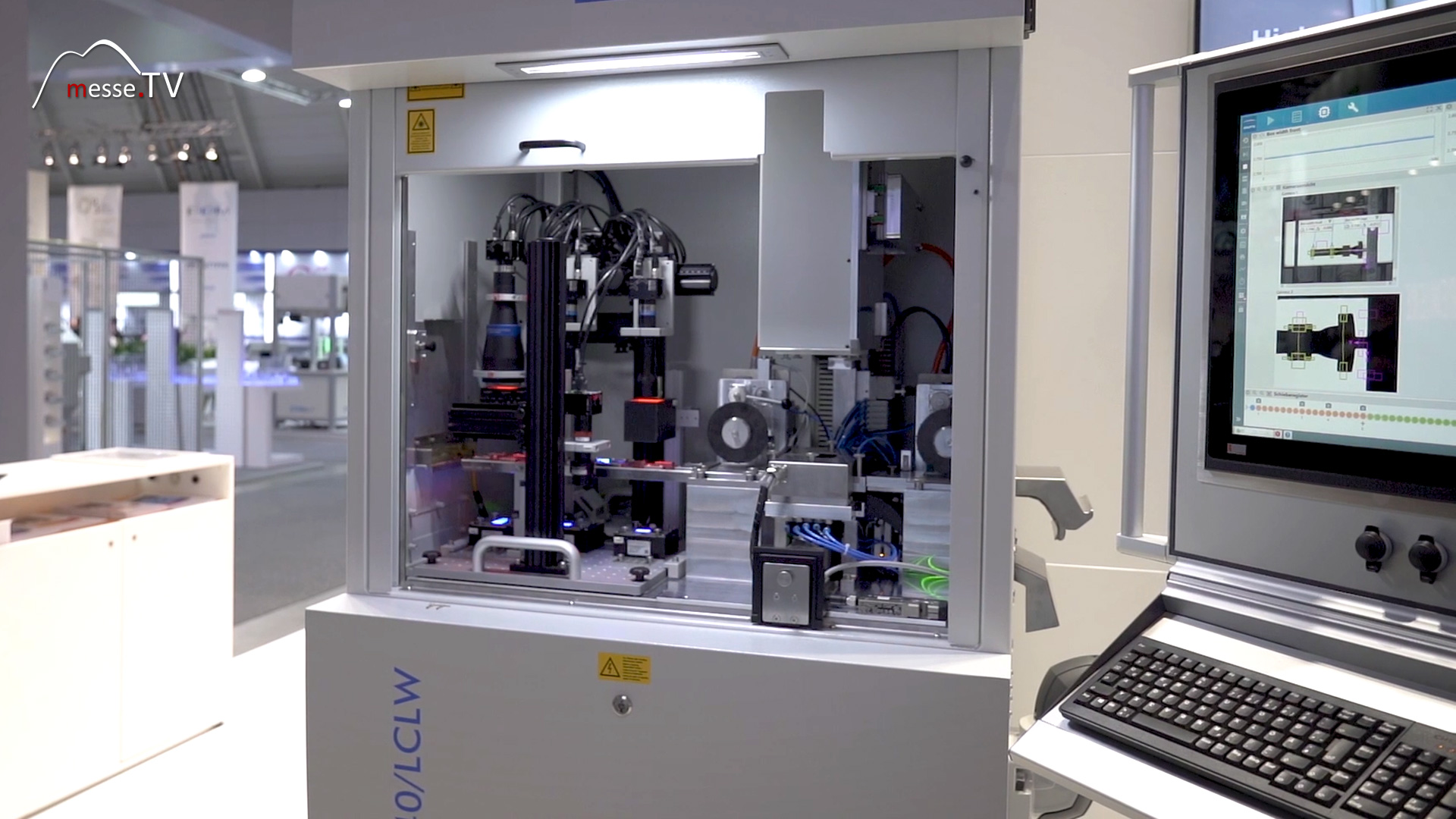

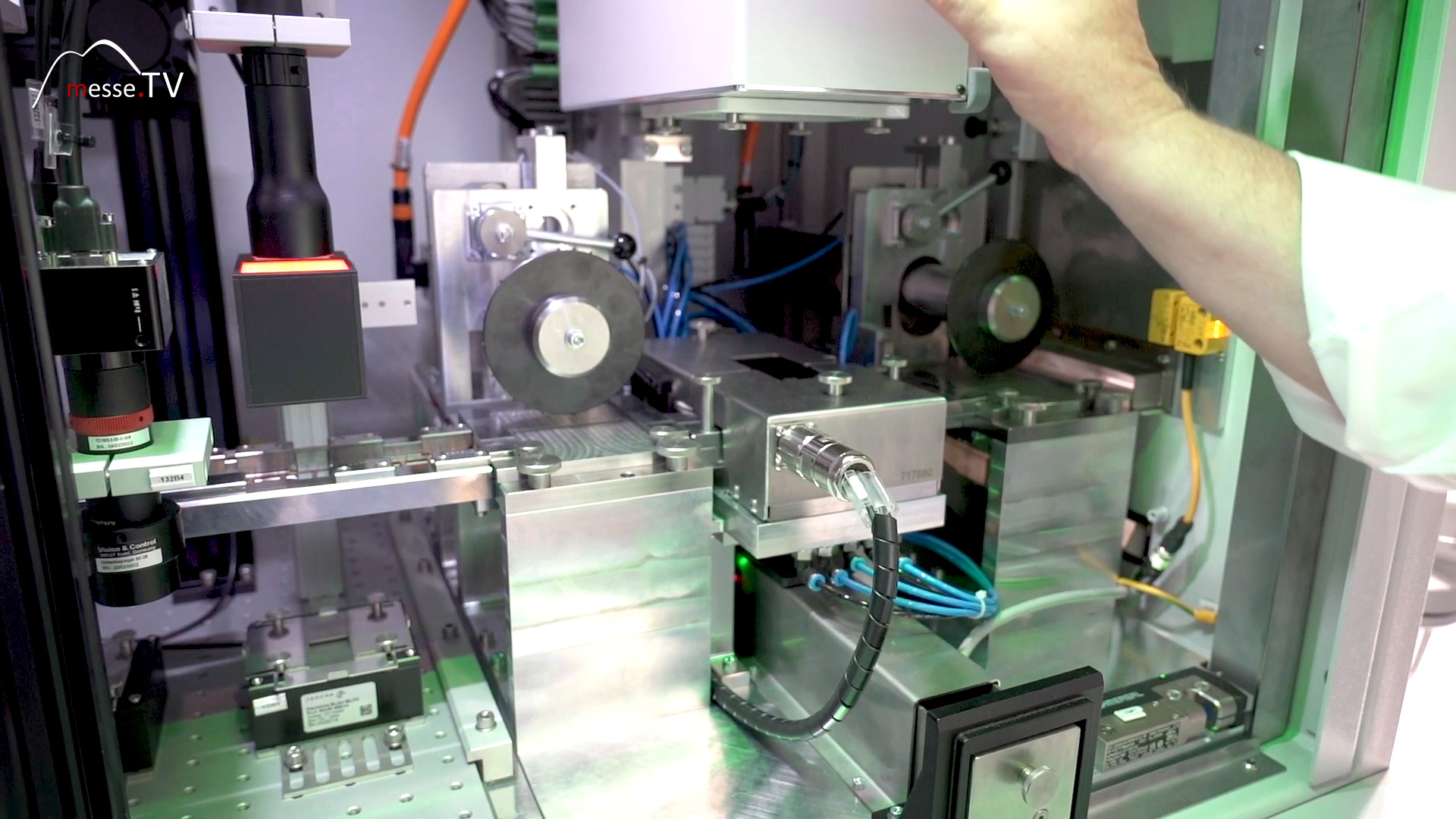

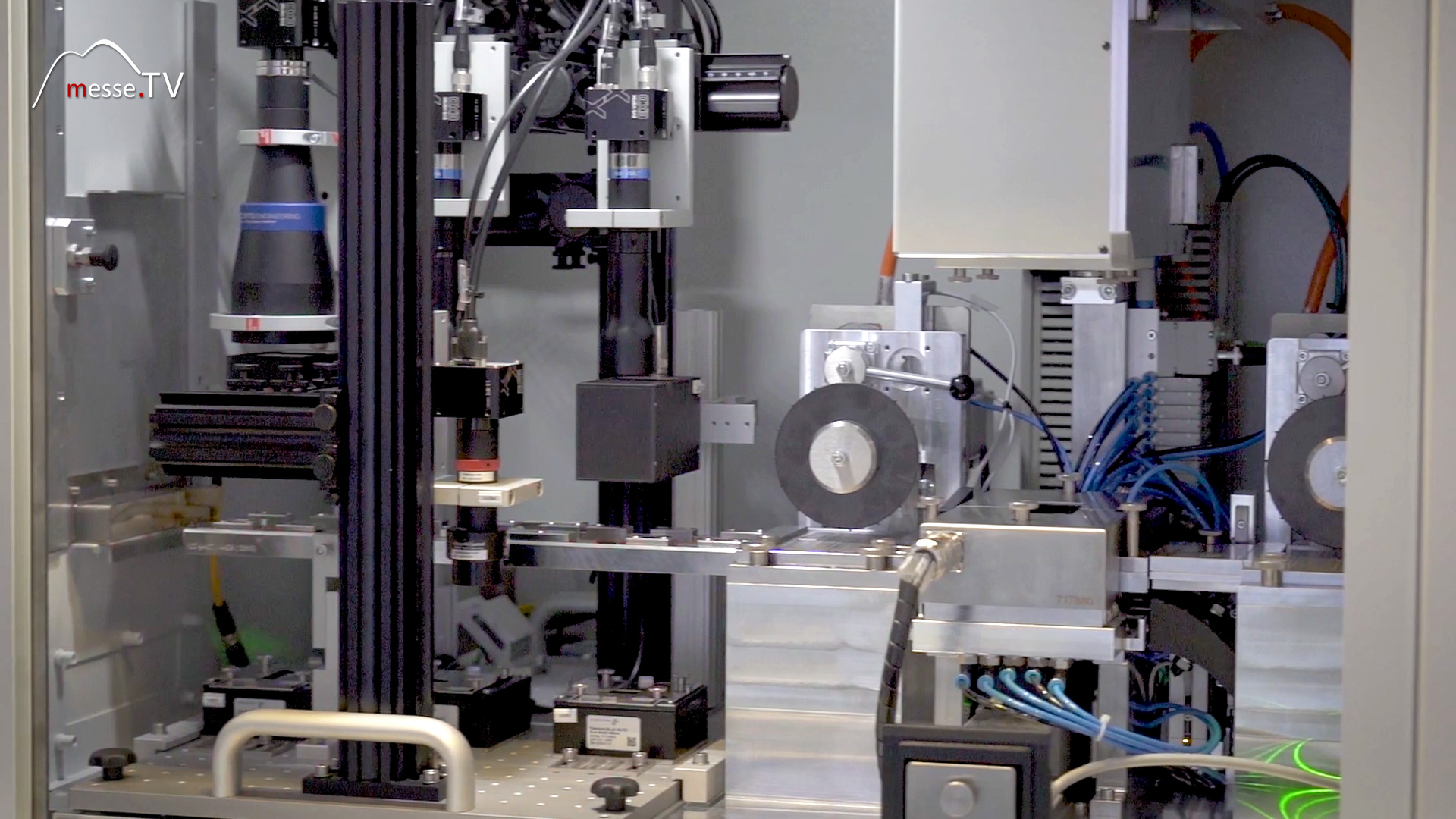

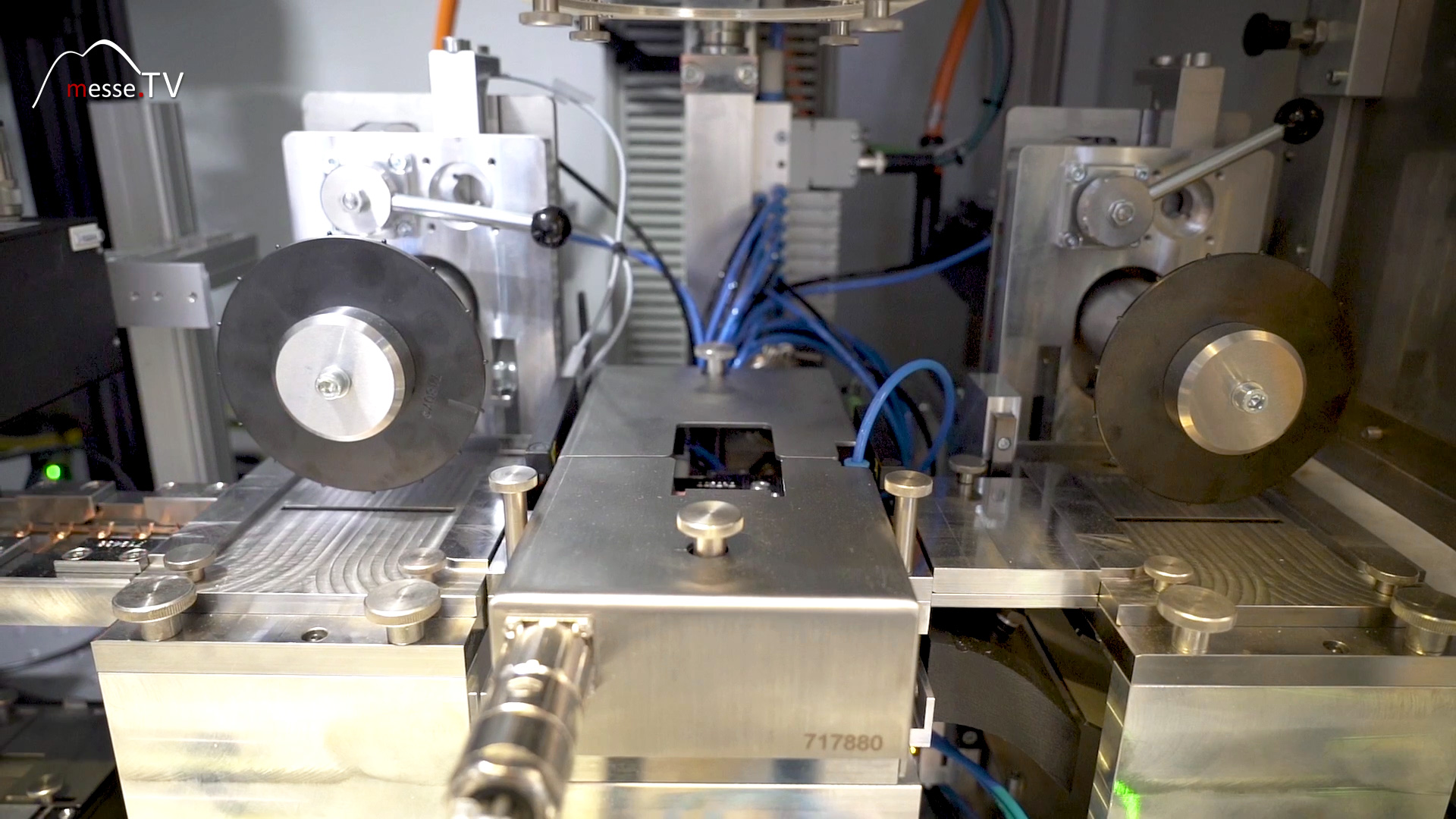

The presentation focuses on the PSS-40 inspection station. It is designed for stamped strips, but is also suitable for applications such as laser cutting and laser welding. The special feature of this solution is the consistent use of an integrated laser. This performs several functions within a single system and replaces mechanical process steps. After punching, the punched strip is fed from the press into the machine via an inlet. There it enters a strip guide in which several cameras, lenses, and lights are installed. The components are captured from different angles, similar to viewing them under a projector. Depending on the geometry, the inspection is carried out from above, from the side or, if necessary, from below in order to cover all relevant contact dimensions.

All parts are inspected completely, not selectively. Image processing immediately detects defects, dimensional errors or other deviations. If a defective part is identified, the system intervenes automatically. The integrated laser cuts the defective part out of the stamped strip in a targeted manner. The cut is not only made at one edge, but at the entire connection to enable clean continuation. After cutting, the remaining strip is rejoined and welded with the same laser. This is followed by a tensile test. Two drive wheels pull against each other with a defined torque to check whether the laser weld is mechanically resilient. Finally, a camera documents the welding process. This not only ensures that only good parts are present on the reel, but also that this status is fully documented.

A key difference between Jenoptik's approach and previous solutions is that it completely eliminates mechanical cutting. In conventional systems, defective parts are separated mechanically and then welded using a laser. However, mechanical cutting always alters the cut edge. These changes have a negative impact on the quality and reproducibility of the weld seam. The purely laser-based approach ensures that the cut edge remains defined and uniform. The weld line is more stable and reproducible, which has a direct impact on process reliability. At the same time, the system operates without wear. It is designed for continuous operation and can be used around the clock without the need to readjust or replace mechanical tools.

The entire process is clearly structured and fully automated:

Consistent quality and complete traceability are crucial in contact manufacturing. The test station presented consistently meets both requirements. It ensures that defective parts do not leave production and at the same time provides complete documentation of all relevant process steps. For manufacturers, this means a significant reduction in scrap, less rework, and greater process stability.

The award given to this solution recognizes precisely this approach. It combines photonics, laser technology, and image processing into an integrated system that can be directly integrated into existing punching lines. This clearly shows how modern inspection stations not only check, but can also actively intervene in the production process and improve it in the long term.