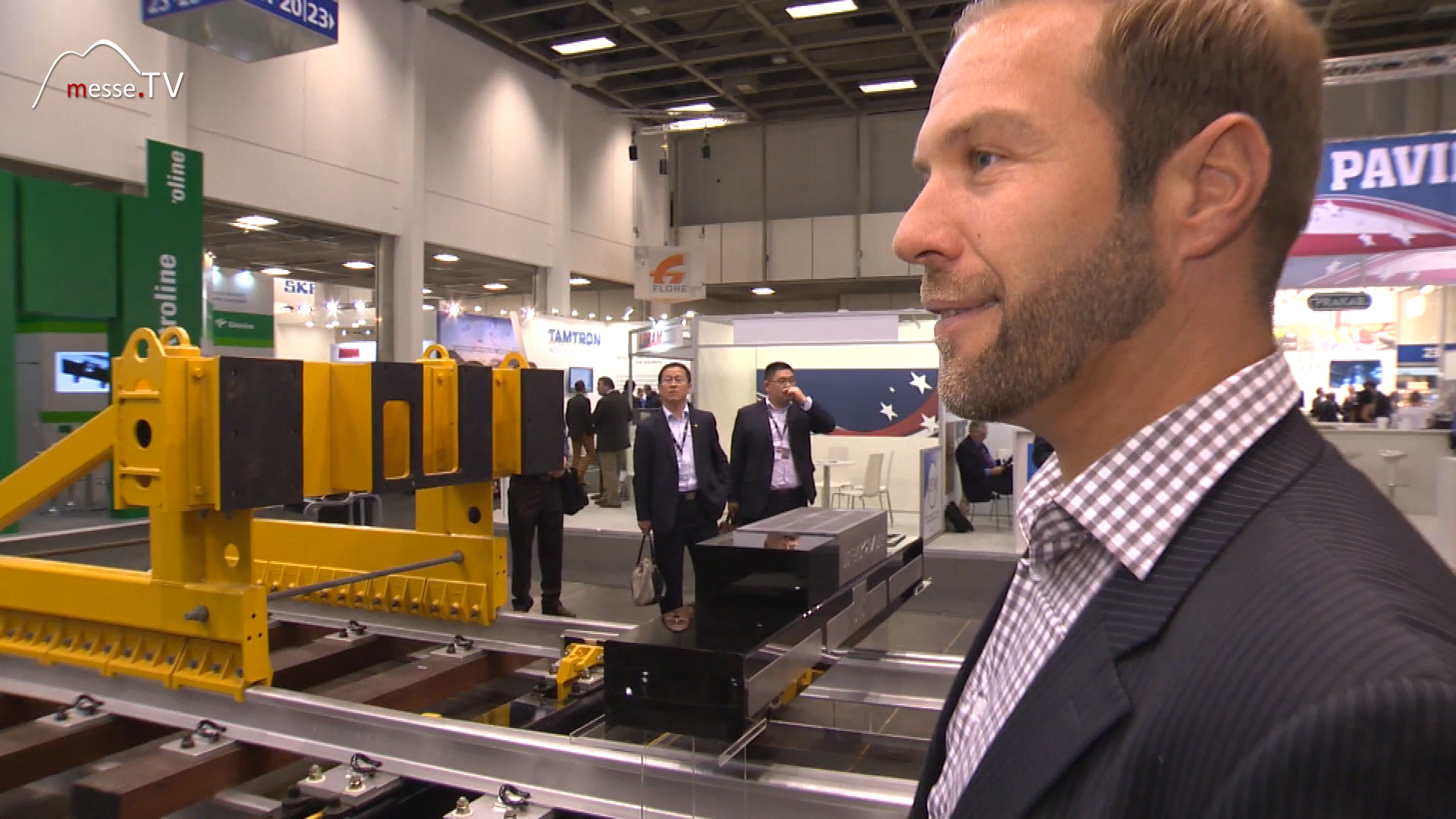

Messe.TV talks to Michael Steidl and Christoph Kürschner from Progress Rail Services - a Caterpillar Group company - at InnoTrans 2016 in Berlin. From track inspections to axle inspections, the company is constantly working on improvements. The focus is on the challenge of heavy goods transport, optimizing economic efficiency and safety aspects.

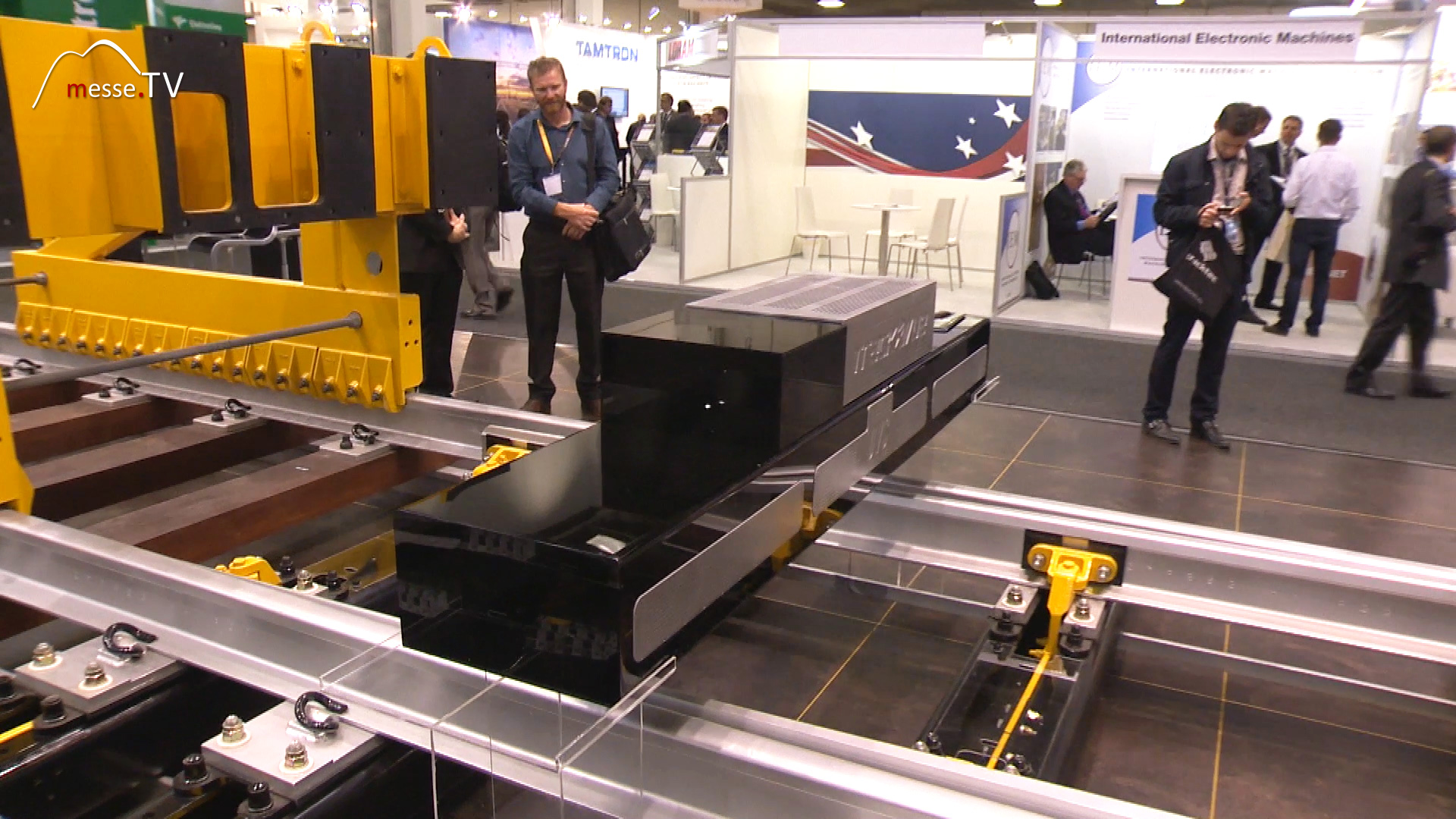

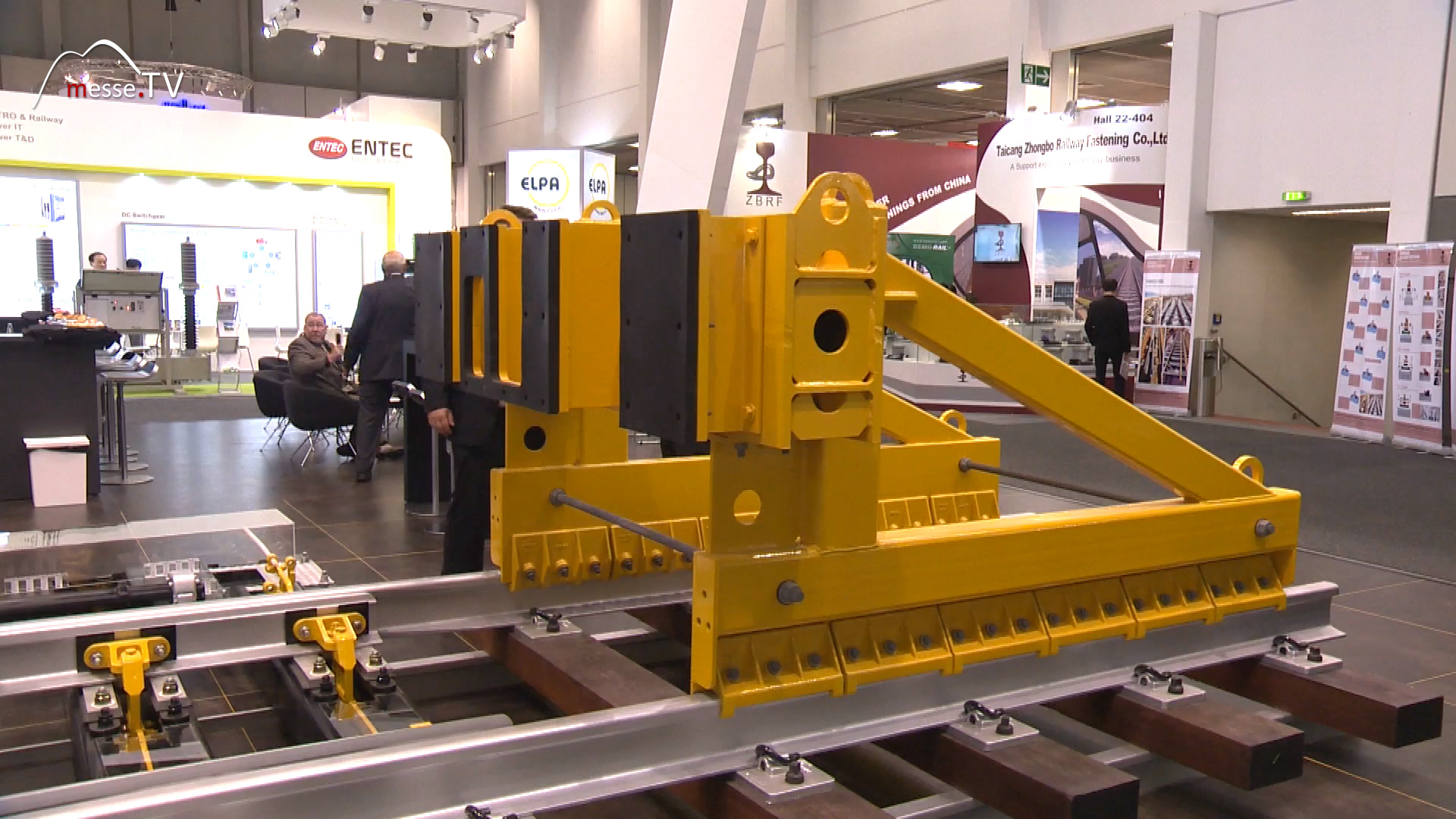

Jürgen Groh: Greetings, Mr. Steidl. What are you demonstrating here at the stand? That looks very interesting. Michael Steidl: Hello, on the one hand we have the buffer stop here, which is manufactured in England - we use it to catch the trains. Right next to it, we are showing the wooden box sleepers for the point machines and the point machines themselves - we can move the points with this entire package. Above you can see one of our new products, which we use to carry out track inspections. This allows us to check whether the fastenings are still intact, the position is correct or whether the rail is OK - in other words, whether the track gauge is correct and the surface of the rail is OK. This is our latest product.

Jürgen Groh: What sets Progress Rail apart from other providers? Michael Steidl: Yes, there are several manufacturers, but we can achieve greater accuracy with our ultrasound technology. Jürgen Groh: Where will the trend go in the next few years? I assume that the technology will continue to develop. Michael Steidl: A major focus - especially because we are very strongly represented in the USA - is to increase the maintenance intervals. We currently have some routes in the USA where the rails have to be replaced every 6 months. We need systems that simply last longer in order to reduce the maintenance window.

Jürgen Groh: In which regions or continents is Progress Rail most strongly represented? Michael Steidl: We have a very strong focus on heavy haul. We are at home in the USA and are also the market leader. In England, we have taken over a company where we manufacture turnouts in order to enter Europe, and we have a plant in Australia, where heavy haul is also a big issue. From there, we are trying to open up other markets such as South East Asia and the Middle East.

Jürgen Groh: In layman's terms, what does heavy haul mean? Michael Steidl: Heavy haul means heavy load, i.e. anything over 35 tons axle load. These are the big, long freight trains that we know from the USA with 100 wagons on one train. They naturally put a lot of strain on the track. You don't really see this anywhere else in the same form as in the USA. It's all very exciting - a completely different kind of track construction than in Europe. Jürgen Groh: Good morning, Mr. Kürschner. Progress Rail and Caterpillar - what is the connection? Christoph Kürschner: Good morning Mr. Groh. We are the only division in the Caterpillar Group that is active in the rail sector. We were bought by Caterpillar in 2006.

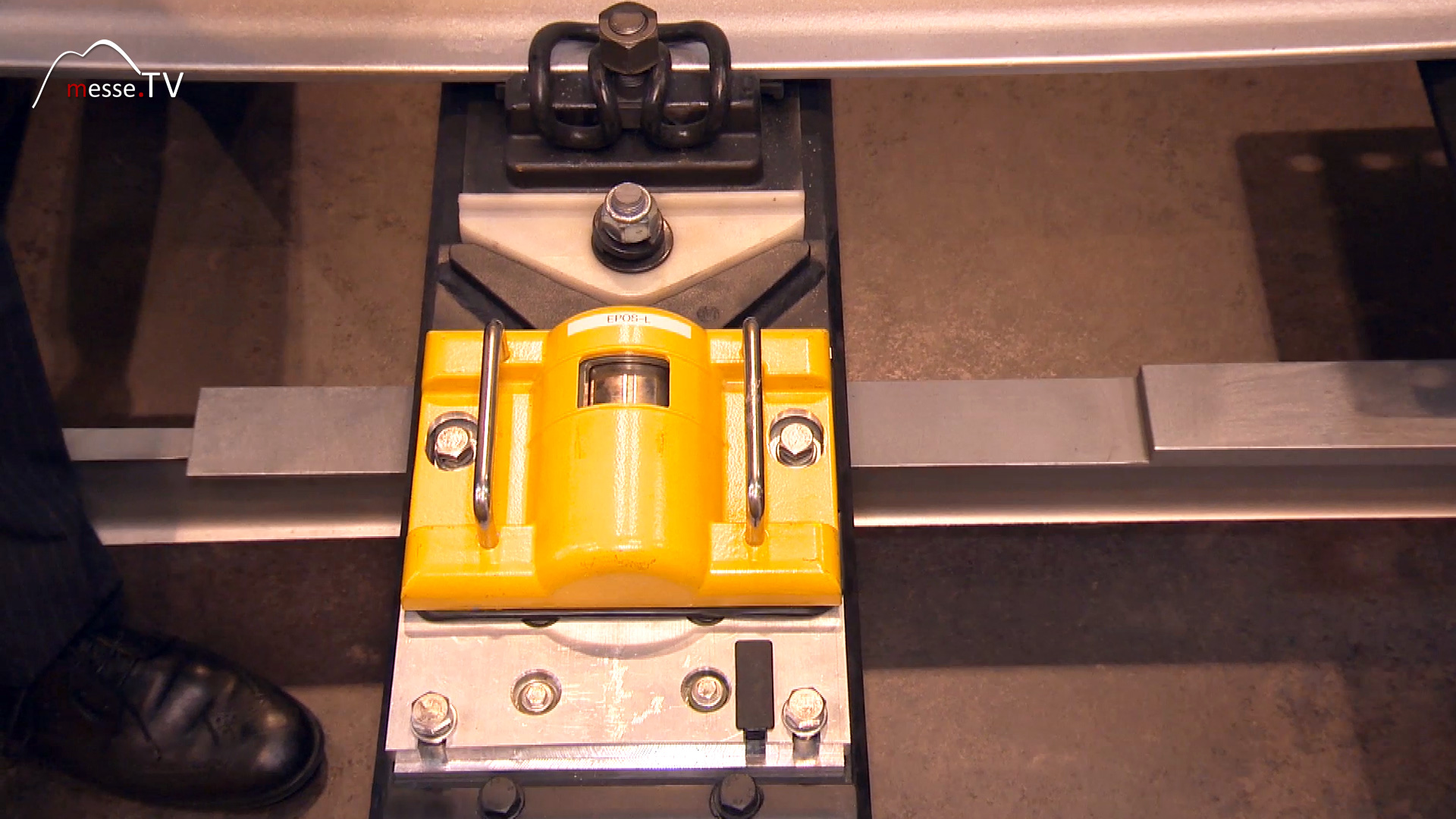

Jürgen Groh: What is being shown here at InnoTrans? I see rails here. Christoph Kürschner: Exactly. We have various safety systems here. Let's start with the Tracking Equipment Detector. This system detects whether something is being dragged under the train. The system is equipped with a shock sensor and a rail switch. The rail switch recognizes which axle is passing and then detects when a shock hits the shock sensor. The hardness of the impact can be detected and the data evaluated. Behind this we have a hot axle box detection system. These systems are currently installed at Deutsche Bahn approximately every 40 kilometers. They measure the temperatures of the bearings, axles, brakes and wheels. The aim is to prevent a train from derailing because the axles have broken or become too hot. On arrival, the rail switches detect that the train is coming. The rail switches count the axles and a flap opens in which a heat sensor is installed. This sensor then measures the temperatures of the axles. Various alarm levels can be set, and when the level is reached, the system recognizes which axle has reached the alarm level. The information is then passed on to the dispatcher or a reporting point via a unit.

Jürgen Groh: What can it actually prevent? Christoph Kürschner: You can actually prevent a train from derailing. Because if a bearing gets hot, it can break completely. The train may then become unstable and derail completely. There have already been accidents in Viareggion in Italy, for example, which can be prevented with a system like this. Jürgen Groh: Progress Rail must be very innovative for Caterpillar to say "we need this". Christoph Kürschner: Let's put it this way, we have been using the systems for several years now. The hot runner detection system is already the third generation. I think the first one was available in the mid-1990s and they are of course being developed further. Jürgen Groh: Where are we heading in this area? Where do we see ourselves in 10 years' time? Christoph Kürschner: It will definitely be the case that we will have to continue to network. Data analysis is becoming increasingly important, customers want to do trendings, i.e. work with the data. I think that's the trend that will emerge in the next few years.