At InnoTrans 2016, Messe.TV will also be at the stand of Langmatz from Garmisch-Partenkirchen. A true specialist for technical system solutions and has been for more than 50 years. The company is primarily active as a system supplier in the telecommunications, energy technology and transport technology sectors. At InnoTrans 2016, the company will be showcasing primarily the transport technology sector.

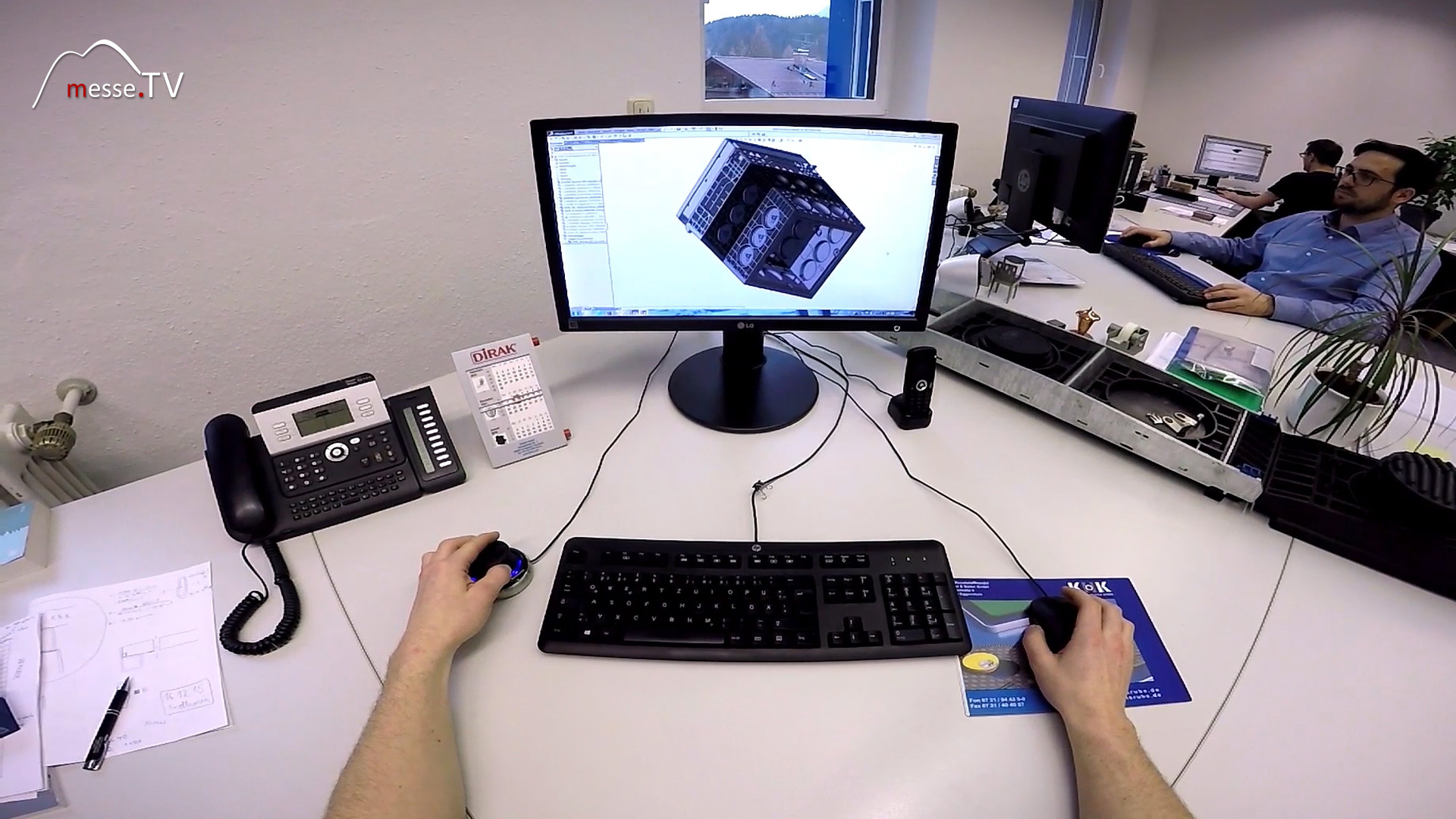

Jürgen Groh: What does Langmatz stand for? Christoph Saller: Langmatz stands for innovative, customer-specific products - produced and developed in beautiful Garmisch-Partenkirchen in Upper Bavaria. With 330 employees, the company is the largest employer in the large tourist region of Garmisch-Partenkirchen. We train our own specialist staff in 13 apprenticeships. This also makes us an important factor for the region. In quotation marks, our products are first and foremost hollow housings. What makes them special are the customer-specific, customer-oriented extensions. We develop and produce our products together with our customers. Jürgen Groh: Who is your target group? Christoph Saller: Our target group is customers from the telecommunications sector, such as Deutsche Telekom. From the transport technology sector, which includes cities with their infrastructure projects, but also the energy sector with energy suppliers, land suppliers and municipal utilities. Jürgen Groh: Do you have an example? Christoph Saller: Here you can see a product that was designed with Deutsche Bahn. This is a joint and multi-length cabinet that is required for fiber optic expansion. A project has been running for years in which the entire Deutsche Bahn lines are being upgraded with fiber optics. If repairs are necessary on the route, fiber optic cabinets with joints are set up at certain points. This means that repairs can be carried out on site. Jürgen Groh: Do you have any other innovations that you can show us? Christoph Saller: Yes, we do. I will gladly hand you over to my colleague Mr. Pfuhl. Jürgen Groh: Do you have another Langmatz innovation for us, Mr. Pfuhl?

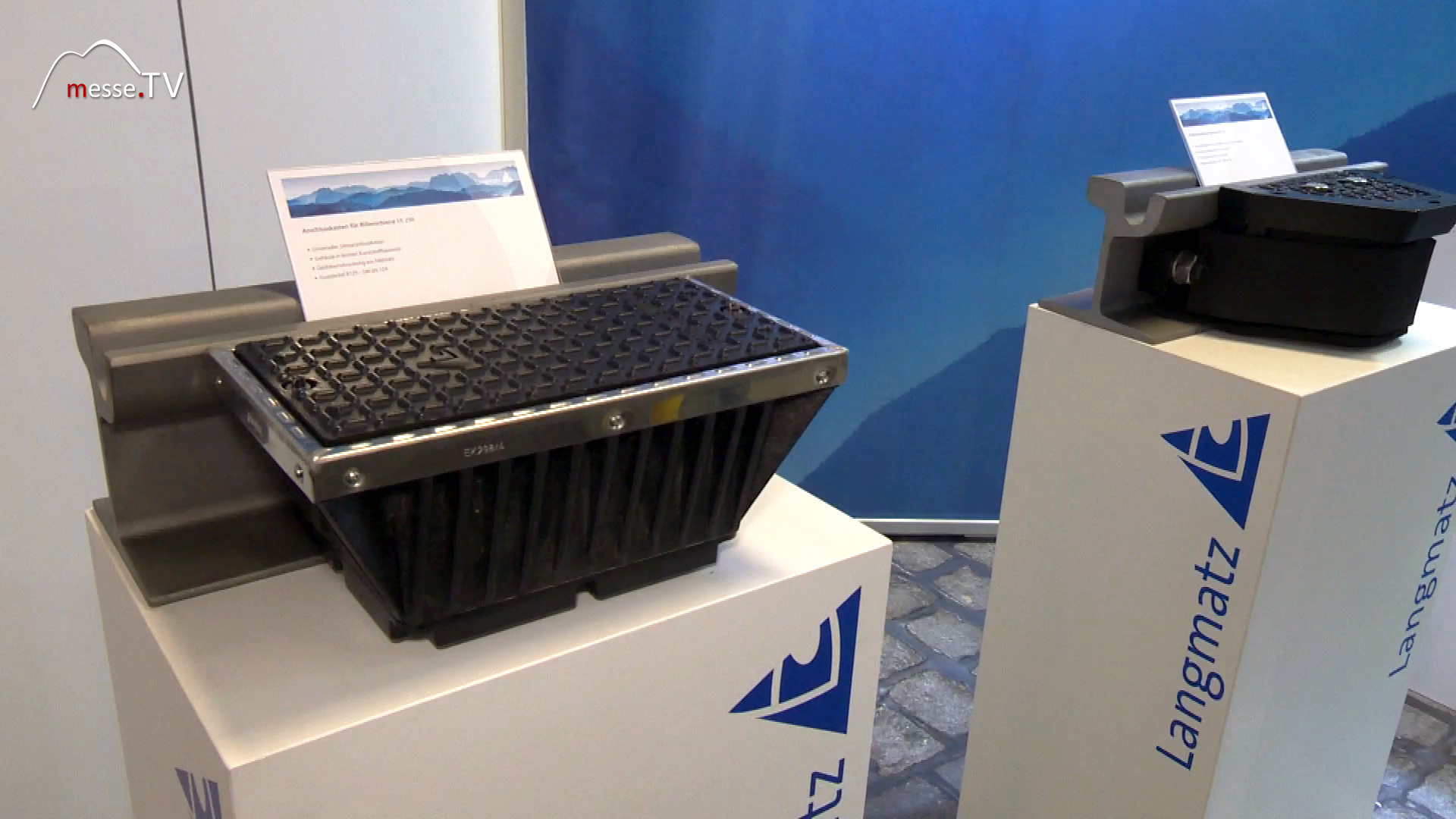

Felix Pfuhl: That's right. Another major area of Langmatz's business is the development and production of plastic cable ducts. There are synergies here in the field of rail transportation technology, especially in the tramway sector. On the ground in front of you, you can see a coupling spool shaft, which is used to speed up public night traffic. The special thing about this shaft is that the cover made of a glass fiber composite material is used to accommodate these switching points, these coupling coils, and these coupling coils then transmit data directly to the traction unit. Jürgen Groh: And what is the advantage of this? Felix Pfuhl: It allows you to ensure that local public transport gets a green phase immediately and doesn't have to wait when it approaches the traffic lights. Jürgen Groh: How does the company stand out from other providers?

Felix Pfuhl: What we have as a unique selling point is WPC, which is a wood-plastic compound, i.e. a plastic with a high proportion of wood fibers. A proportion of up to 45% wood fibers is of course ideal for municipalities that are looking for a green fingerprint. Jürgen Groh: How can we imagine this on site - how does this box sit in the street? Felix Pfuhl: What is shown in white in our model is the surface of the road, for example asphalt or cobblestones. This shaft is then inserted there, with the epoxy resin cover on the surface. The coupling coils could also be installed directly in the road. The great advantage of the manhole solution is that the road does not have to be torn up for maintenance and repairs. You can open the cover and replace defective parts or carry out measurements if necessary. Jürgen Groh: So you don't have to tear up the road at all? Felix Pfuhl: Yes, you can save yourself that. Jürgen Groh: That's already a big advantage. Is there already a specific project you are working on that we might see in 2, 5 or 10 years' time? Felix Pfuhl: We work very closely with our customers and also try to carry out customer-specific projects and respond to their wishes. For this reason, it's difficult for me to say that we'll be presenting something completely new in two years' time - that will happen in the near future. There are of course ongoing projects. It's not possible to make a real forecast at the moment, but of course we'll stay on the ball. Jürgen Groh: We are excited and look forward to meeting you at InnoTrans in two years' time. Felix Pfuhl: With pleasure. Thank you very much.