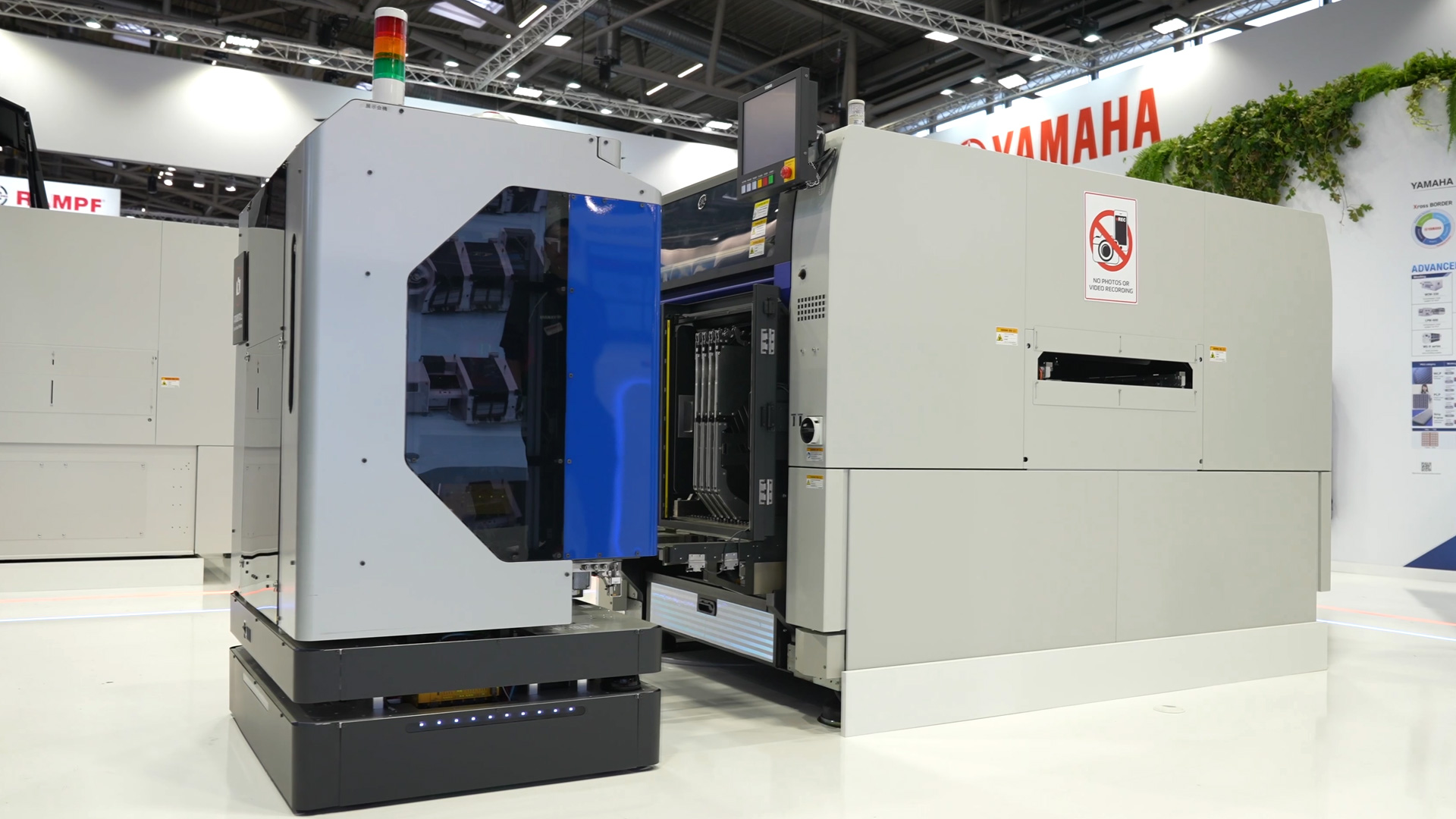

Yamaha YRM20 with AI feeder system for fully automatic SMT feeding

by J. Groh - 2025-12-04Speed, precision, and efficiency are crucial in electronics production. A new solution now promises complete automation in the field of SMT feeding – with a highly integrated feeder system that not only automatically supplies components, but also transfers them to the placement unit without human intervention.

Component supply without operating personnel: the YRM20 feeding platform in detail

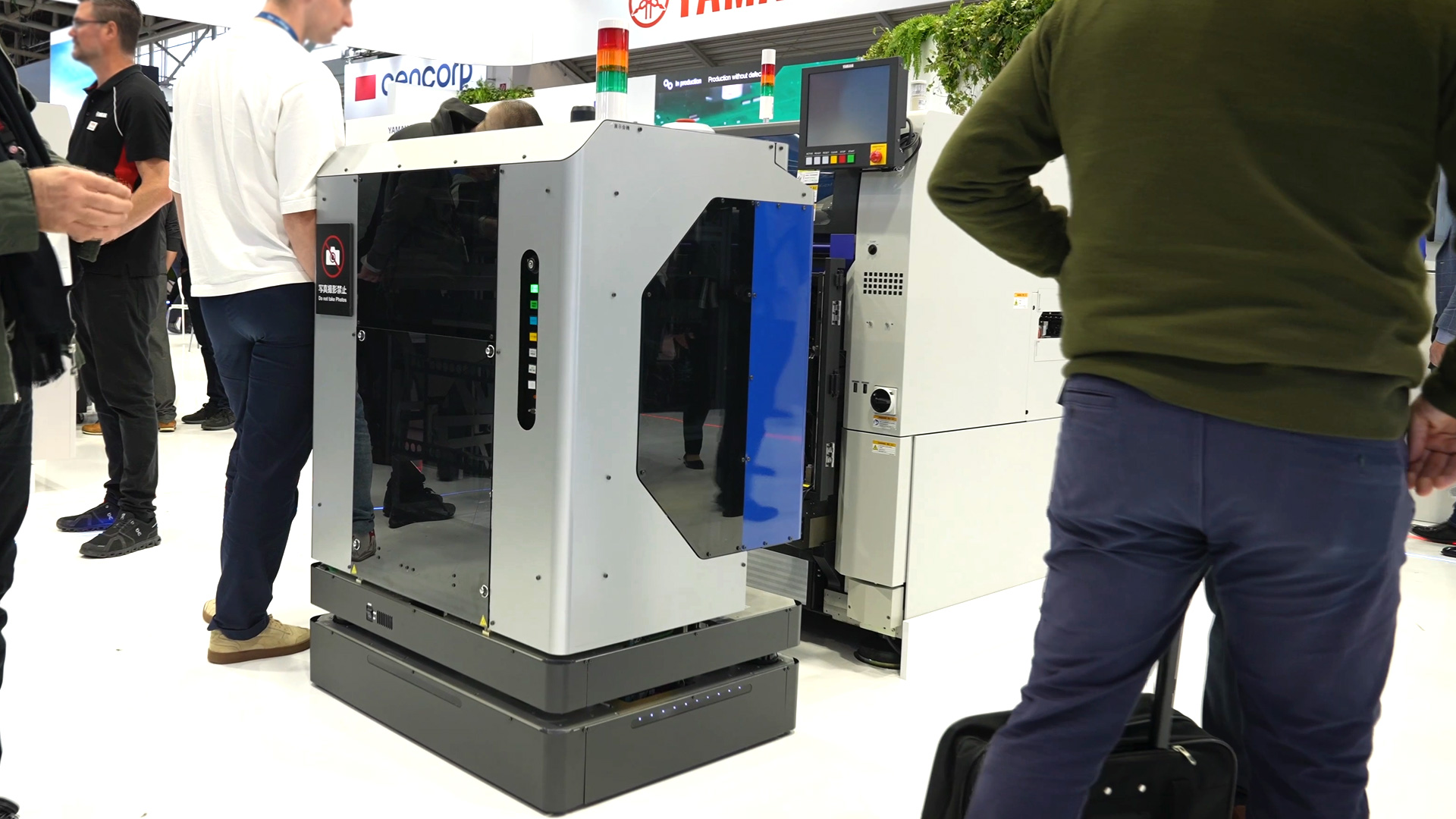

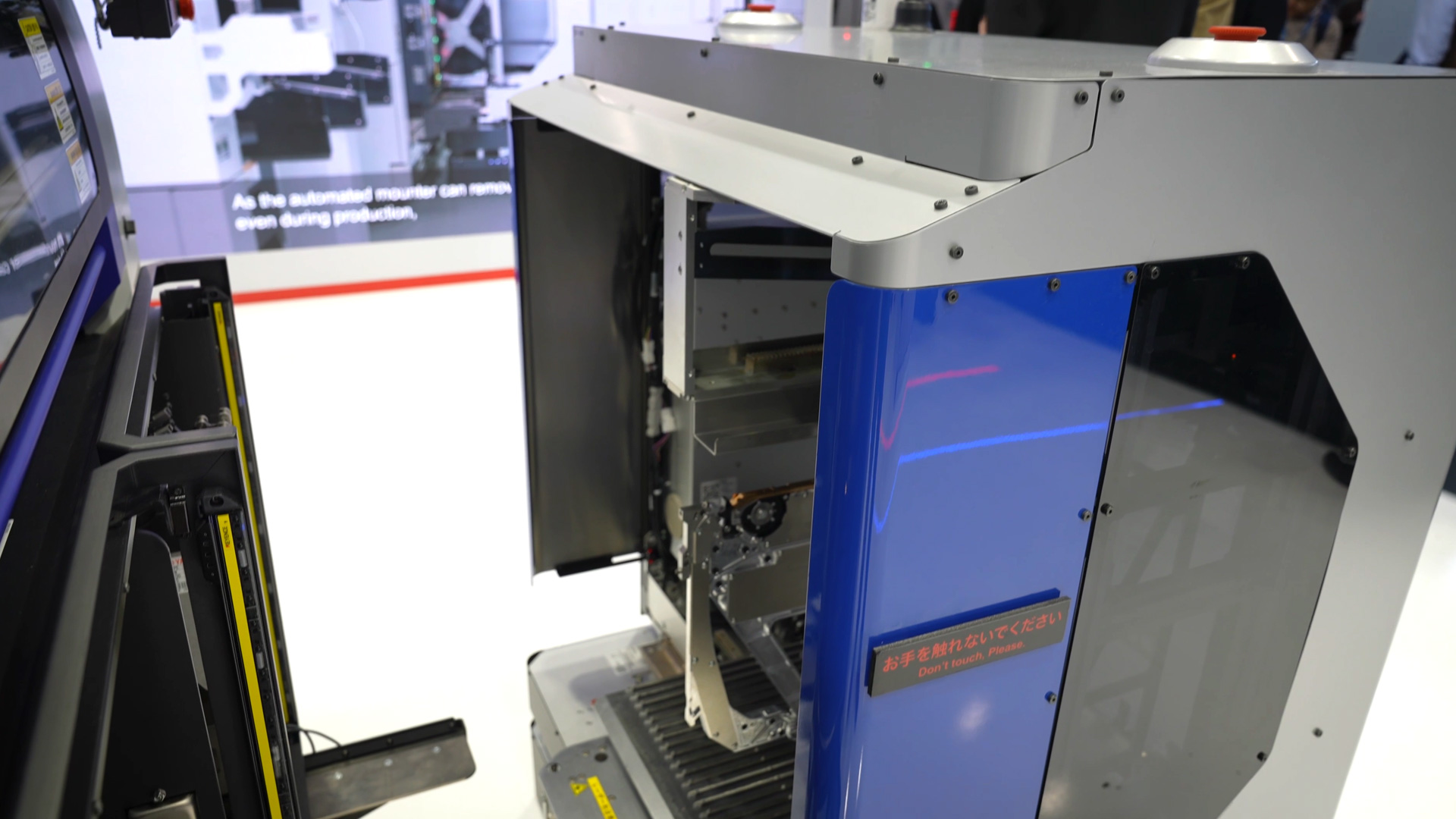

The platform presented is a prototype that appears unremarkable at first glance, but in detail represents a profound change in SMT manufacturing. All components required for assembly are provided via an automated feeder system. The transfer to the placement machine takes place without any manual intermediate stages – purely software-controlled, reliable, and precisely timed. The entire process chain is designed in such a way that no personnel are required for component supply.

Programmable supply with AI and sensor technology

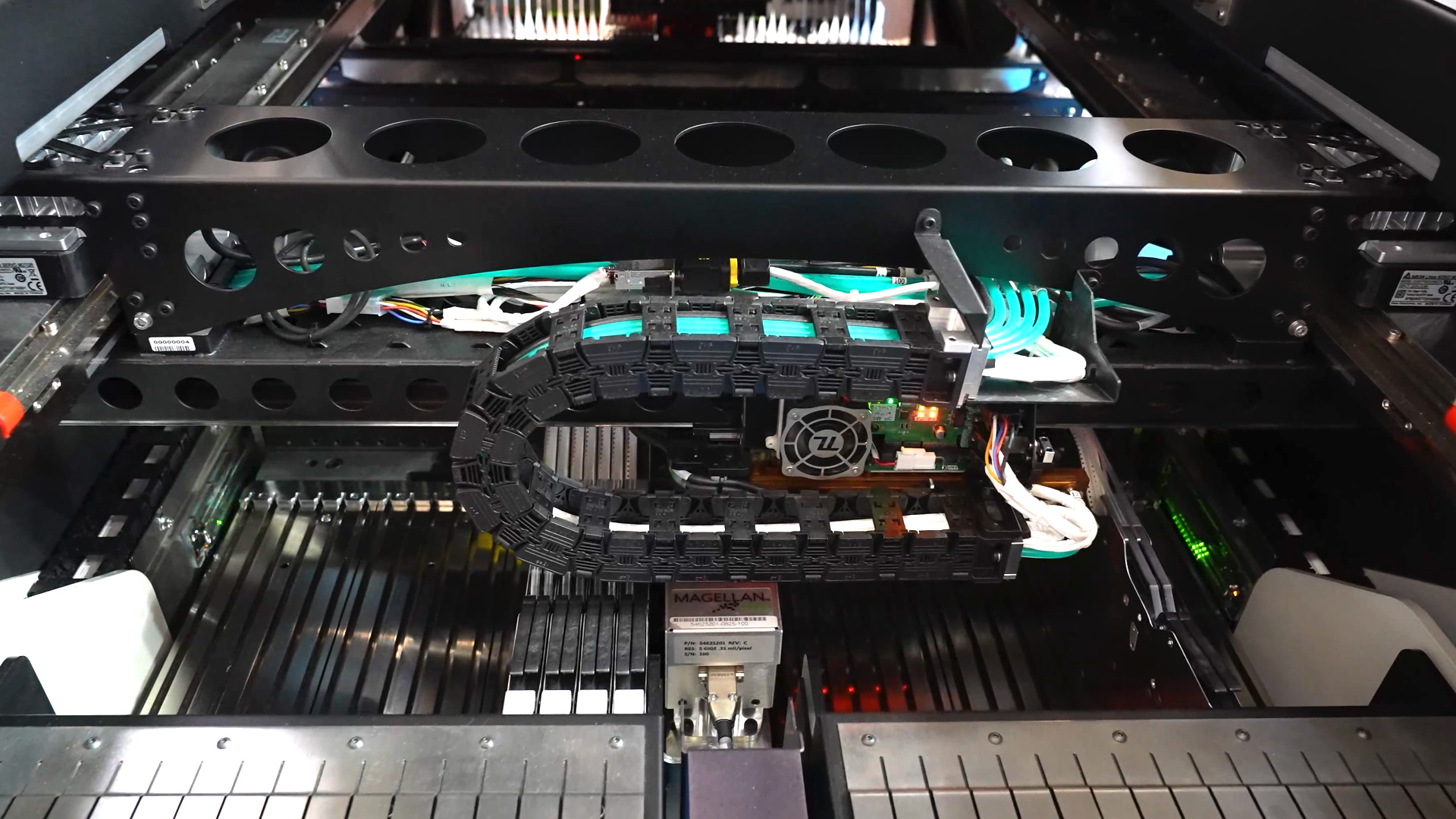

The platform combines classic feeding technology with artificial intelligence and high-resolution sensor technology. This not only recognizes when which components are needed, but also controls their exact position on the way to the machine. The process is programmable and takes place in real time. Sensors ensure that the transfer takes place exactly at the intended location – error-free and without interruption in the process.

End-to-end automation right up to the machine platform

The system combines feeder logic and machine platform in a holistically integrated structure. Components are not only provided, but also transported directly to the machine platform without manual intervention. There, the system uses built-in sensors to detect the exact position of the transfer and stops precisely at the designated location. Manual intervention is neither necessary nor intended. The system has been developed in such a way that it not only automates processes, but is also structurally optimized for a completely unmanned supply line.

Target group for the Yamaha YRM20: High-volume production with high personnel costs

The solution is designed especially for manufacturing facilities with multiple parallel SMT lines. In companies with large production volumes, component feeding often represents a high personnel cost. This is exactly where Yamaha comes in: The new platform significantly reduces the need for operating personnel. The system is designed to enable production with minimal personnel – ideally even without an operator.