Universal Instruments introduces EPIQx, a new generation of placement platforms for electronics manufacturing. The system combines high placement performance with precise positioning accuracy and consistent data-driven maintenance. For PCB manufacturers who want to further develop their production towards lights-out manufacturing and Industry 5.0 concepts, EPIQx will become the central hub in the SMT line.

At the heart of the system is its ability to place components at high speed and with consistent accuracy. The machine achieves up to 90,000 placements per hour while maintaining an accuracy of approximately 25 micrometers. These performance data are crucial for manufacturers who have to meet tight cycle times while processing different assembly variants. As modern electronic products have increasingly shorter innovation cycles, there is a growing need for machines that deliver high speeds and respond flexibly to changing production requirements. EPIQx combines these requirements in a platform that efficiently addresses both large series and highly varied projects.

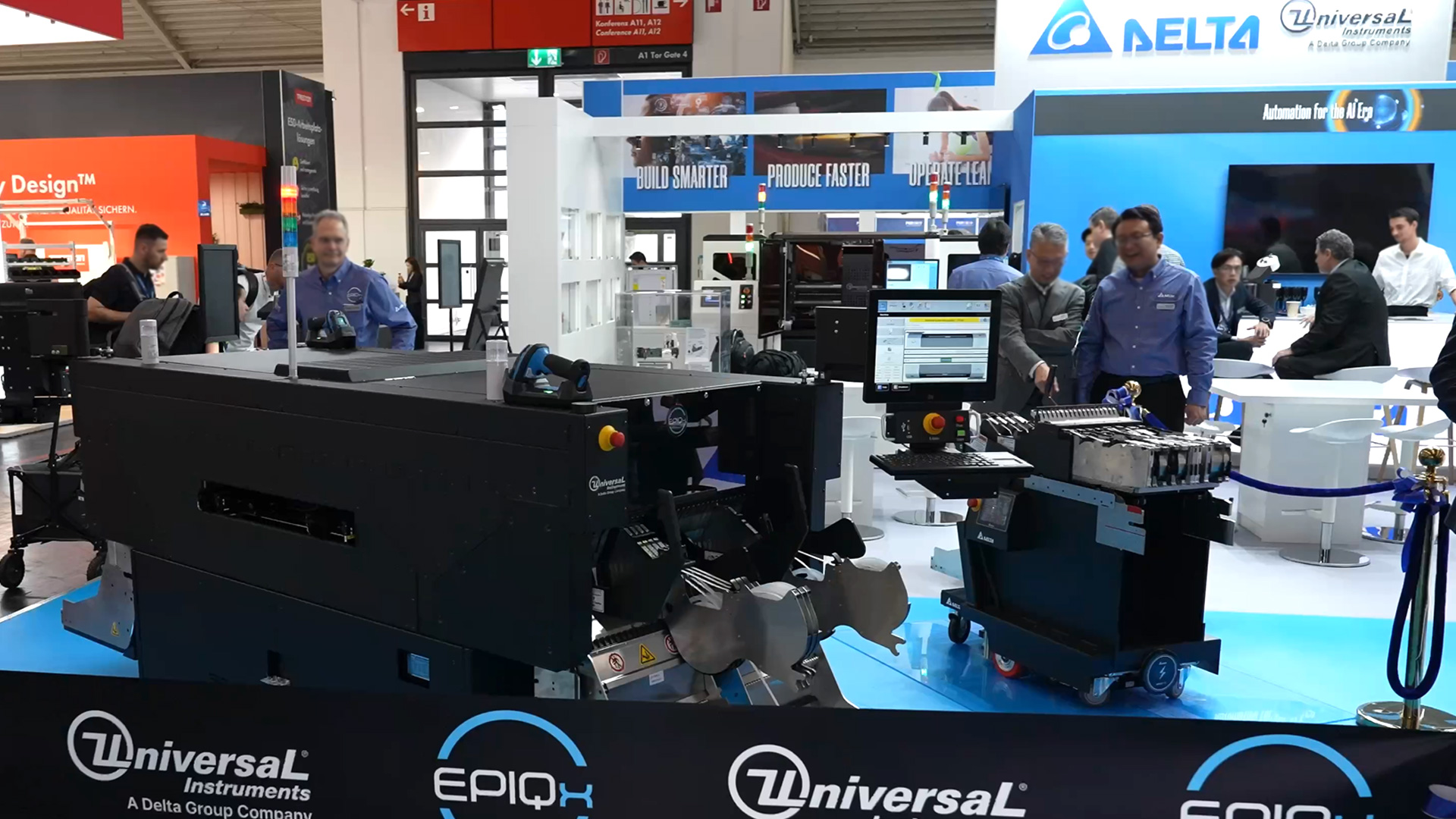

The platform takes on the role of a chip shooter in the production chain. Components are removed from tape-and-reel systems, positioned, and placed on the circuit board with high repeat accuracy. The precise mechanics and high axis dynamics enable short distances, fast pick-and-place operations, and consistent quality even during long shifts or high utilization. Demonstrations, such as at productronica, showcase the platform's capabilities: from tiny 0201 components to larger, taller components, the platform demonstrates a wide range of real-world handling scenarios. For electronics manufacturers, this means that even heterogeneous designs can be processed with a single machine – an aspect that reduces changeover times and line complexity.

A key feature of the platform is the sensor technology deeply integrated into the machine. Each micro module contains numerous measuring points that record status data: movement parameters, vibrations, material flow, deviations in the pick or place process. This data is not lost, but flows back into the software, where it is analyzed and evaluated. This creates a predictive maintenance system. Instead of reacting to malfunctions or adhering to fixed intervals, the platform recognizes early indicators of potential failures. Even small changes that would hardly be noticeable in everyday use indicate that components need to be readjusted or parts replaced. In electronics manufacturing, where even short downtimes lead to high costs, predictive maintenance is becoming an economic factor. Since unplanned failures are the biggest cost driver, the transition to data-based maintenance models significantly increases actual machine availability.

Electronics products demand increasingly compact yet more powerful components. EPIQx covers this development by reliably processing components of various sizes. This includes small formats such as 0201 as well as larger memory and logic components or housings with taller designs. The processing of larger components with a height of up to approximately four millimeters is becoming particularly important, as increasing computing power and data density require more complex housing designs. The platform is designed for these requirements and can handle the mix of miniaturization and growing performance demands without adapting the machine structure.

In addition to speed and sensor technology, reliability plays a central role. The platform is designed for continuous operation – even in environments with three shifts per day or high temperature fluctuations. This is complemented by a globally available support network that provides technical assistance at any time. In an economic context, return on investment comes to the fore. Since downtime causes disproportionately high costs, the economic benefit of the platform is based on its availability. The combination of robust hardware, comprehensive sensor technology, fast error analysis, and close support results in high uptime and thus faster amortization.

Universal Instruments is positioning EPIQx as a building block for electronics manufacturers who want to technologically renew their SMT environment while improving their overall economic efficiency: fast, precise, sensor-based, and with a view to increasingly automated, data-driven production. Increasing connectivity, growing data volumes, and high flexibility in production require systems that can automatically evaluate data, detect deviations, and react independently. EPIQx is geared toward such concepts and forms the technical basis for manufacturing environments that can run largely autonomously in the long term. With the growing importance of AI in the manufacturing environment, the ability to evaluate data from hundreds of sensor points is becoming a decisive competitive advantage. The platform shows how intelligent machines can optimize production processes – from component handling to maintenance planning.