Electronics manufacturing is under high pressure in terms of cycle times and quality, while at the same time there is a shortage of qualified specialists for complex programming tasks. Viscom is therefore expanding its software suite with vAI Provision – a solution that combines proven measurement technology and image processing with artificial intelligence. The aim is not to relinquish decision-making, but to simplify programming and parameterization so that new products can be integrated into AOI systems more quickly, reliably, and reproducibly.

vAI Provision is the latest addition to the Viscom software suite. The company has been using AI methods for many years, for example for image segmentation in automatic optical inspection. On this basis, an assistant for operators was added, which is already in use in numerous installations and supports daily work on the systems. vAI Provision now takes this a step further: the software makes it much easier to program new products for AOI systems. The basic inspection strategy remains unchanged—it is still based on established measurement technology and image processing. What is new is that AI significantly shortens the path to the finished program. Based on CAD data, the software automatically assigns components, creates inspection features, and uses machine learning to support parameter optimization. What was previously a complex configuration process is now a process that leads to a runnable program with just a few steps.

The caption emphasizes that vAI Provision noticeably relieves skilled workers without replacing their knowledge. Many steps in program development are considered tedious work, but require a deep understanding of electronics, solder joints, and error patterns. This is exactly where AI comes in: recurring patterns are automatically recognized, parameters are automatically suggested, and test areas are set appropriately. The AI does not take over responsibility, but rather structures the process. Experts retain control over the result, intervene when special cases arise, and can make specific adjustments to the system. Transparency is particularly important: vAI Provision shows which decision was made at each step—for example, when assigning components or selecting test windows. Confidence values show how certain the AI is about an assignment. Areas with low confidence are clearly marked so that operators can check and correct them in a targeted manner.

Another aspect of the solution is its origin. Development, manufacturing, and data science are based at Viscom in Hanover. The company's own data scientists work on the AI models, which are integrated directly into the software. The systems are built and tested at the site and shipped worldwide from there. This anchoring enables short distances between practice and algorithmics. Feedback from electronics manufacturing flows directly into further development, and AI models can be adapted to real production conditions. The company emphasizes that AI is understood as a supplement to existing technology, not as a black box. Decisions remain traceable, and quality reports document the results of AI applications, especially in areas such as automotive electronics or other mission-critical applications.

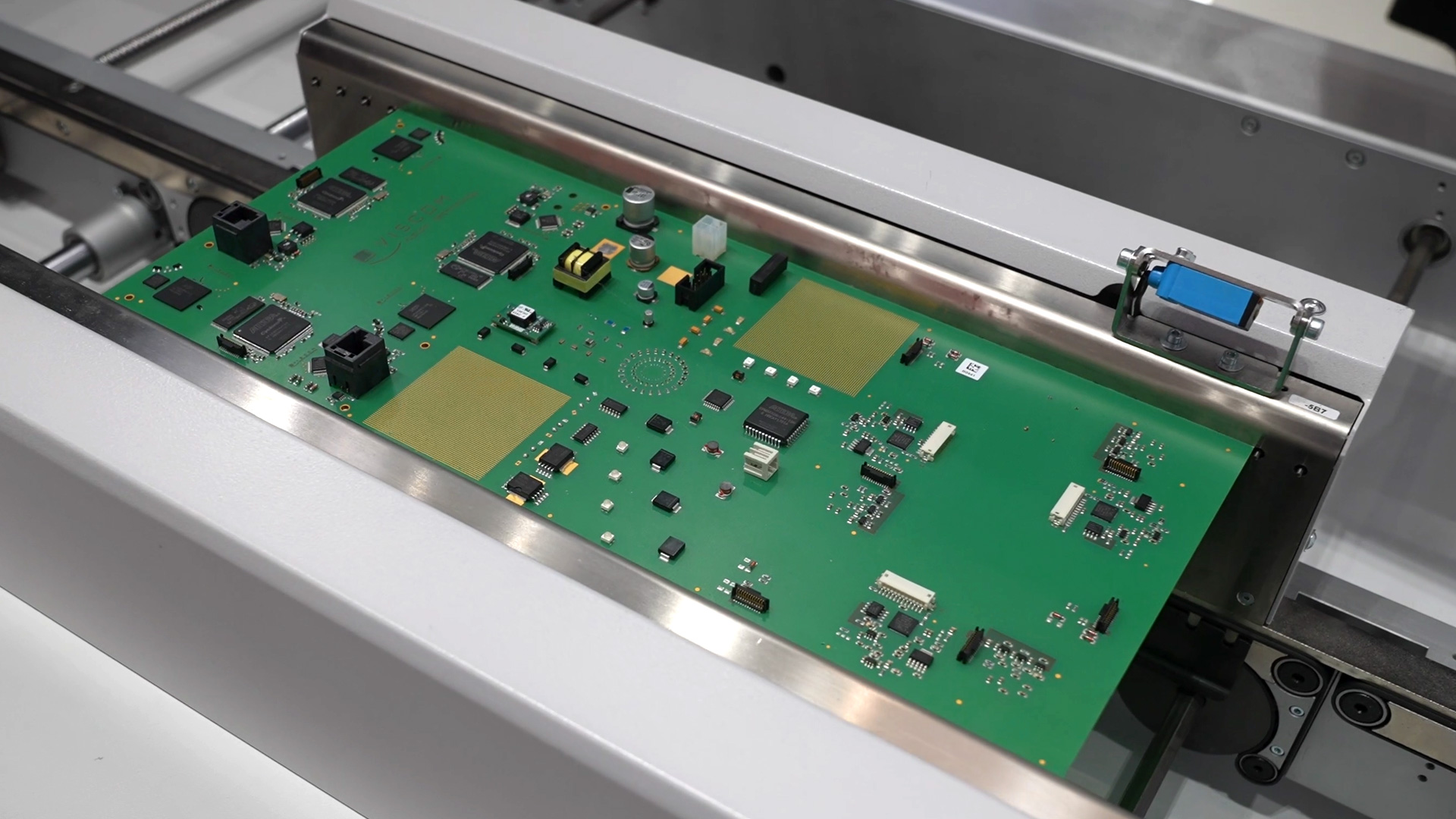

In practice, it's about more than just convenient operation. AOI systems in electronics manufacturing often run continuously, lines operate in seconds and must perform repeatable inspections over many years. The systems are equipped with numerous axes, perform 3D inspections and repeatedly move to positions in the micrometer range with precision. If the AOI system finds a deviation on an assembly, the software provides the operator with comprehensive information. The aim is to clearly assess defect patterns such as lifted leads, uncoated pads, or poor solder joints—regardless of whether the assembly will later be used in a vehicle, in aerospace, in safety-critical devices, or in high-quality consumer products. In this environment, Viscom deliberately positions itself on the basis of defect detection and system quality, not on the lowest sales price. A reliable AOI platform shows its strengths particularly in areas where every single defect can be critical. vAI Provision fits in here as a tool that accelerates programming and parameterization without shifting the production process to an opaque AI structure.

The caption makes it clear that Viscom places its systems worldwide – with a strong foothold in Europe and additional presence in Asia and North America. In markets where not only cost but also quality, traceability, and long-term stability count, the company's AOI solutions offer an alternative to purely price-driven offerings. vAI Provision fits into this strategy: AI is used specifically to reduce programming times, make programs more robust, and relieve the burden on skilled workers. At the same time, the combination of measurement technology, image processing, mechanical precision, and experienced system design remains the foundation of the inspection solutions. For manufacturers who depend on reliable error detection in critical applications, this creates an offering that combines technological innovation with a transparent quality philosophy.