MYPro I51z with GenI software from Mycronic: AOI programming in record time

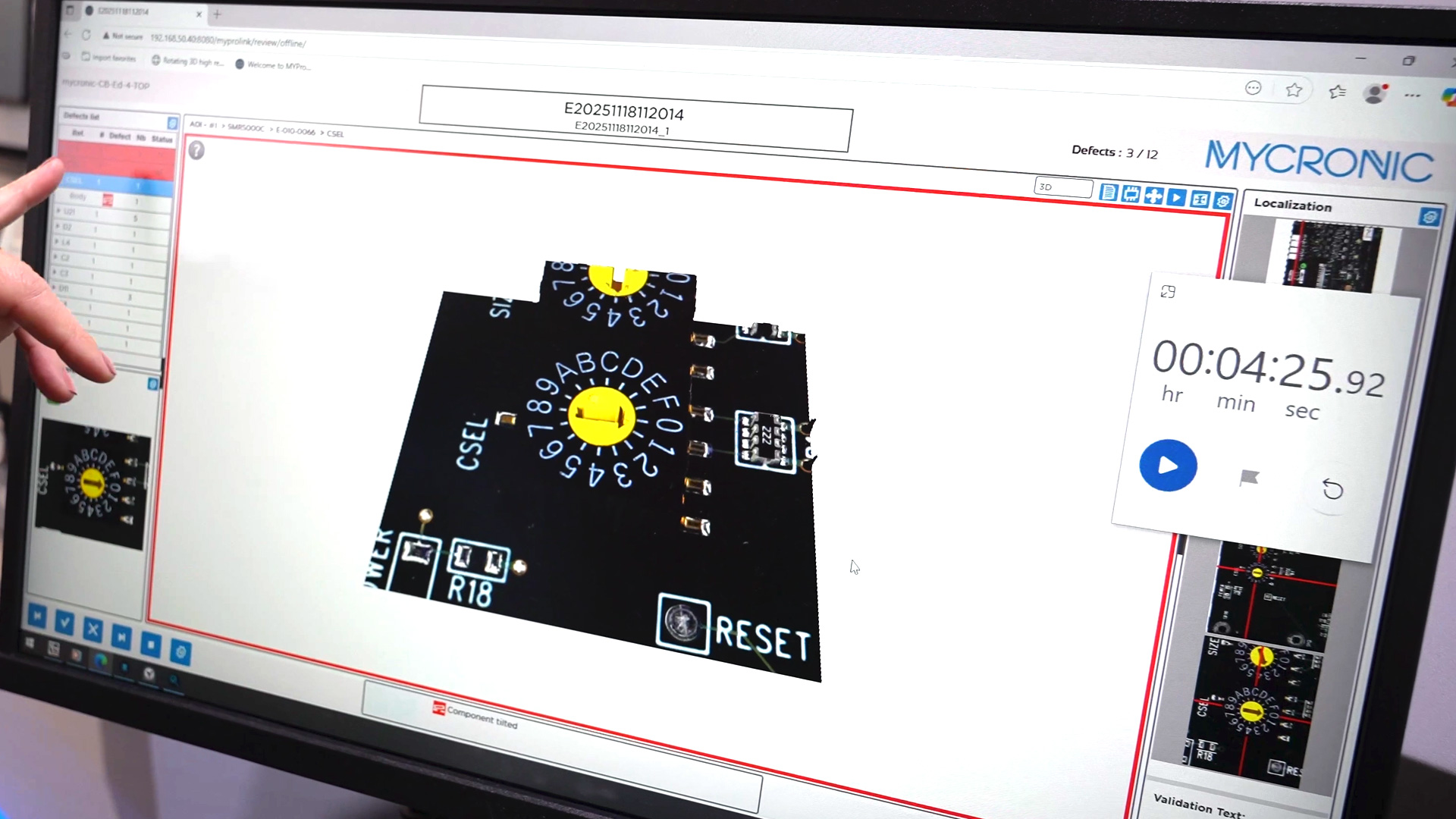

by B. Velonavy - 2025-12-05With the new MYPro I51z, Mycronic presents an AOI system that eliminates the need for conventional programming processes. The GenI software enables fully automated inspection without a reference board – a functional program is ready for use in just four and a half minutes.

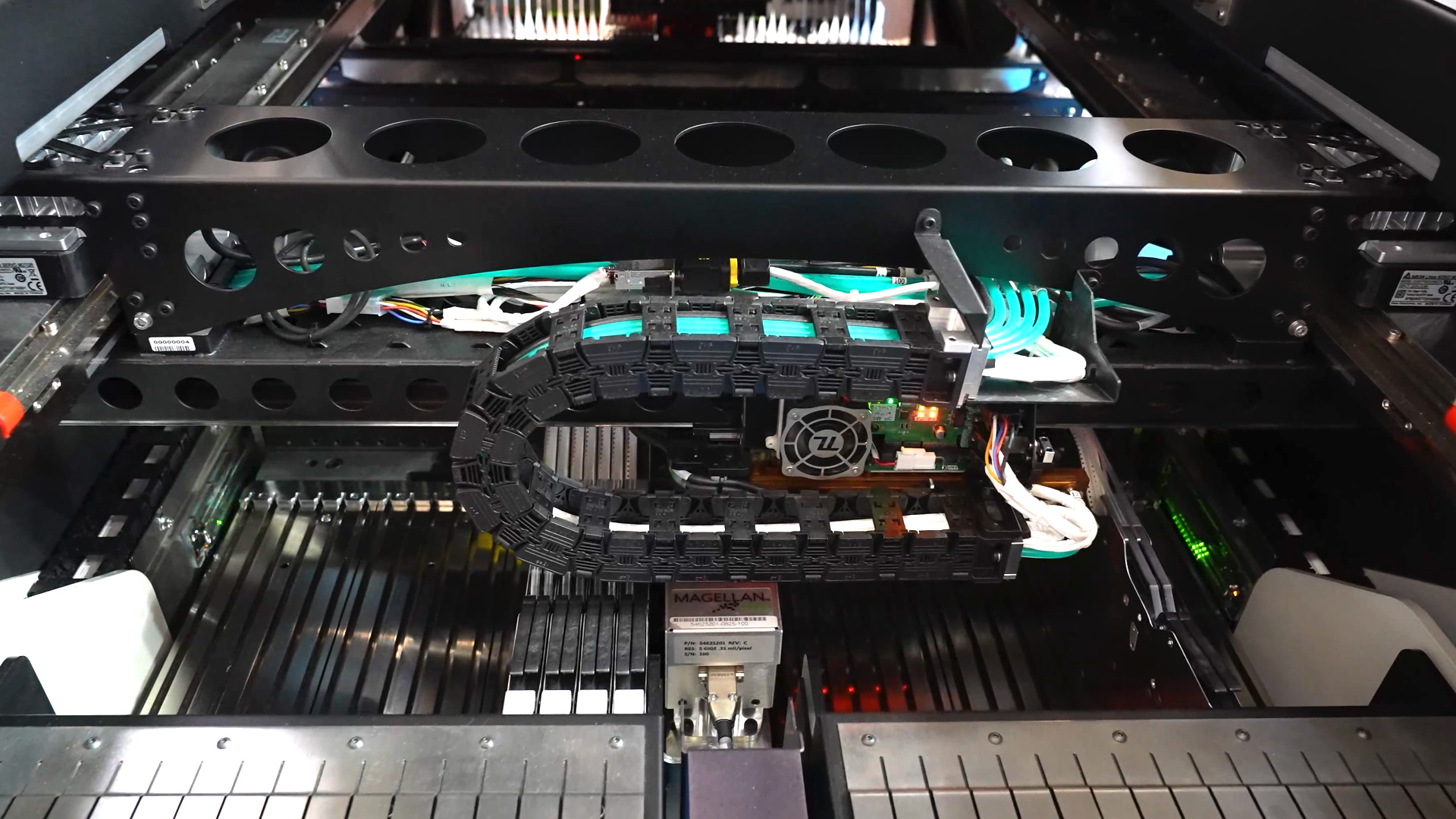

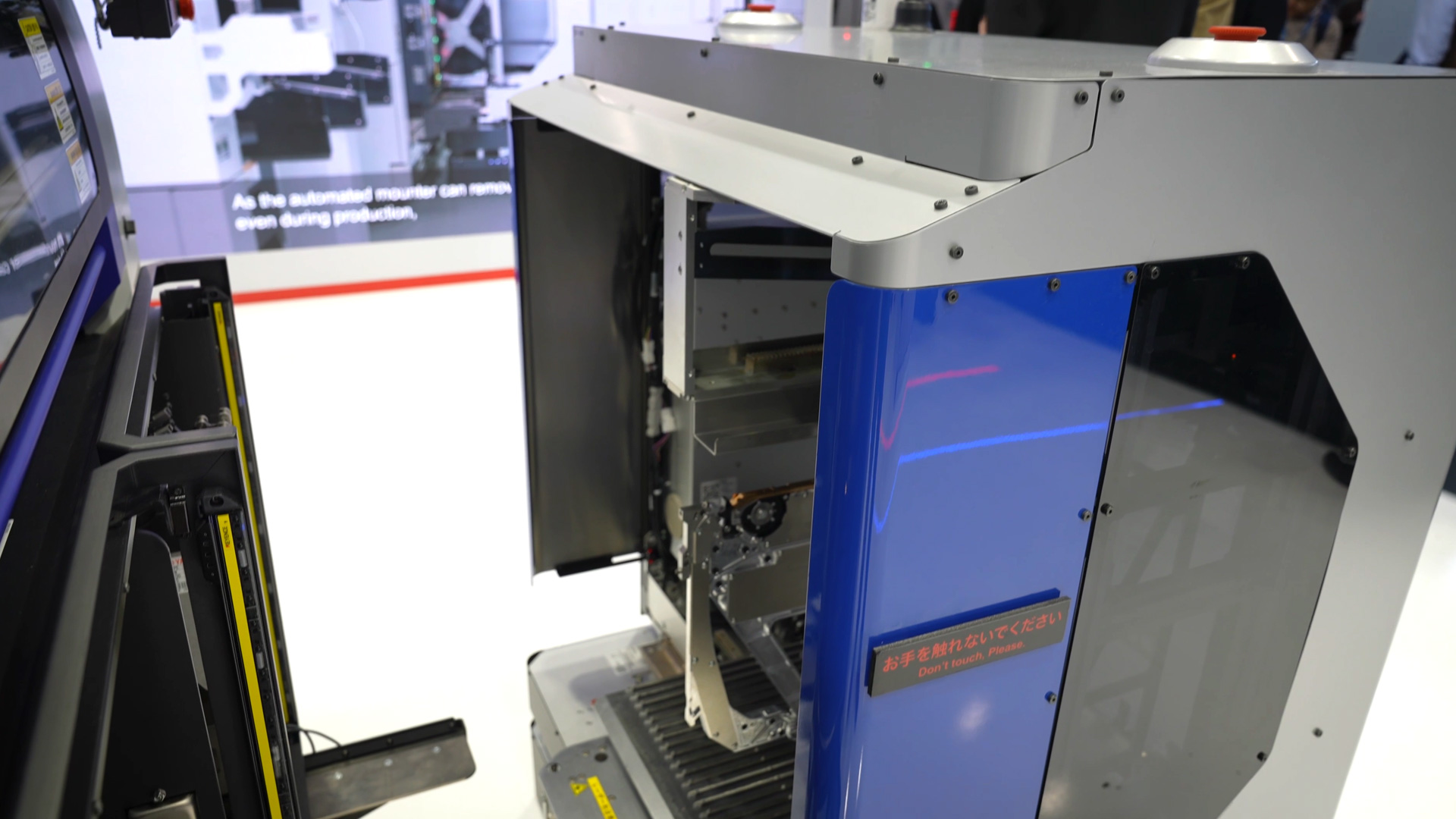

With the MYPro I51z, Mycronic is launching an AOI machine that sets new standards in automated optical inspection. At the heart of the system is the GenI software, which generates a fully automated test program – quickly, precisely, and without the need for traditional programming. In combination with intelligent sensor technology, 3D measurement technology, and artificial intelligence, a new level of inspection quality is achieved, which is particularly advantageous for medium to high quantities.

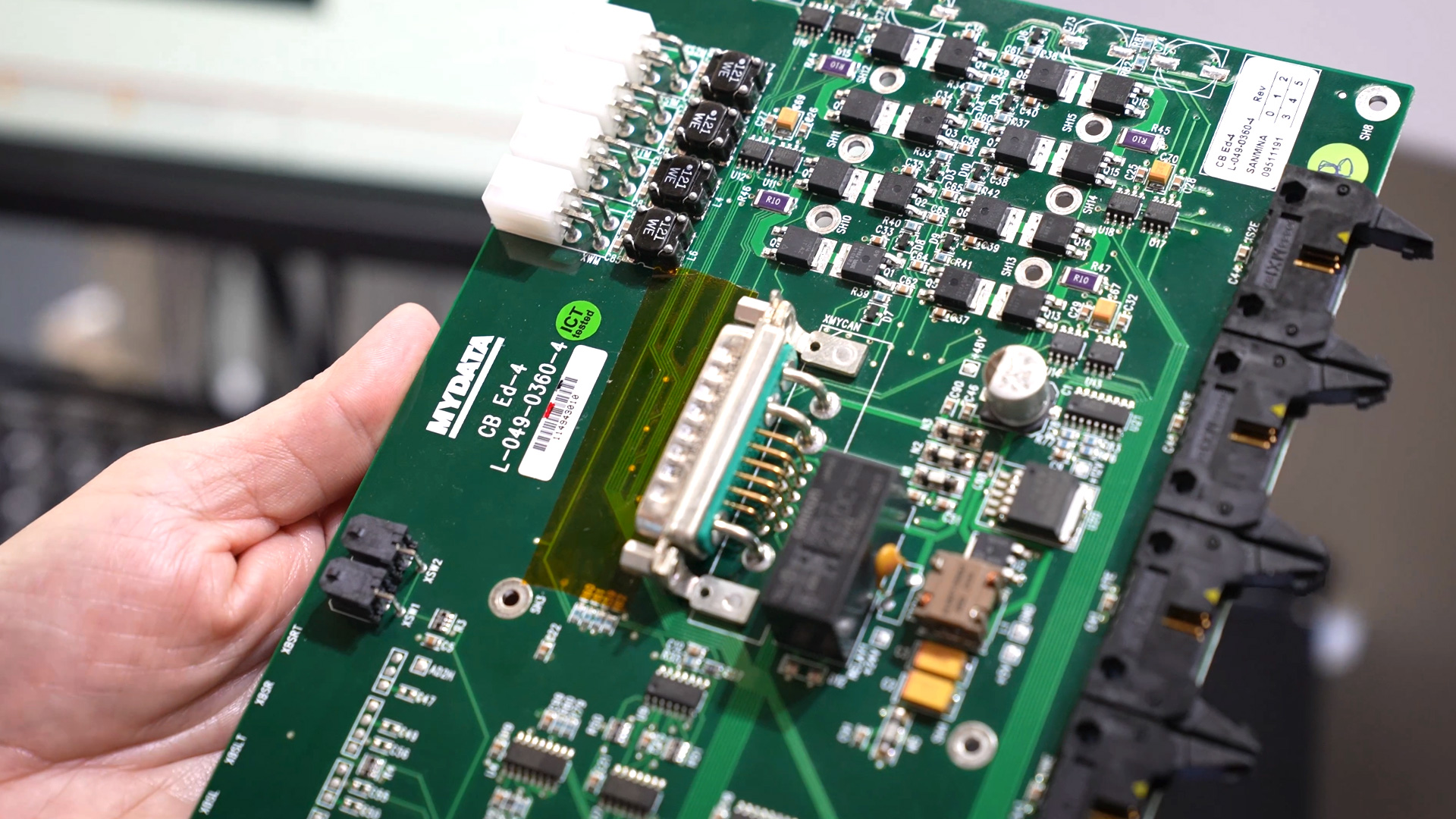

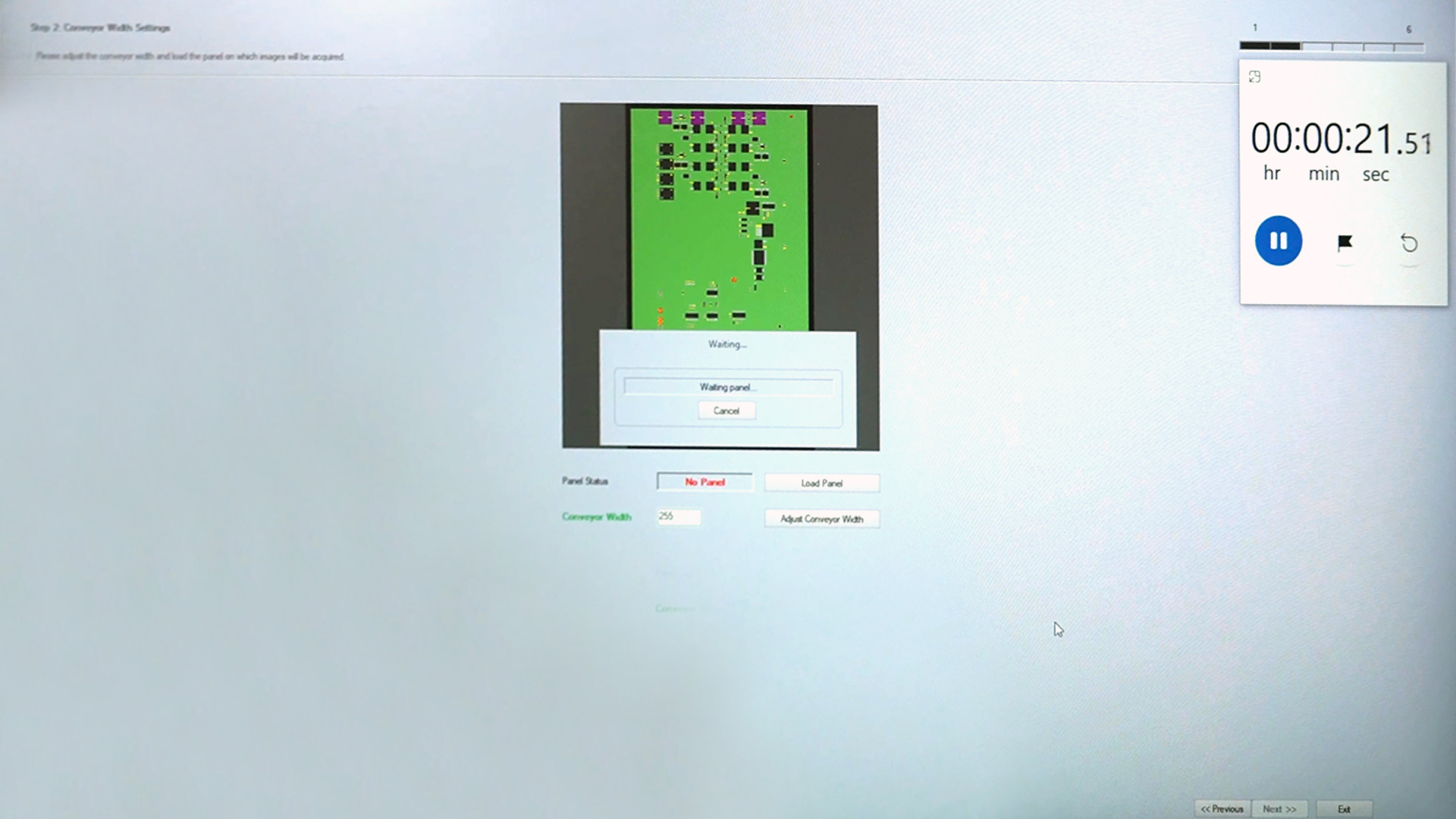

An outstanding feature of the MYPro I51z is that it completely eliminates the need for conventional preparations such as reference boards or manually maintained libraries. Instead, the machine uses an already assembled and functional printed circuit board as a basis for automatically generating an inspection program. After the board is inserted, the layout is recognized, the component positions are recorded, and a test program is created—without any manual intervention. This not only saves time but also significantly lowers the barriers to entry for using AOI technology.

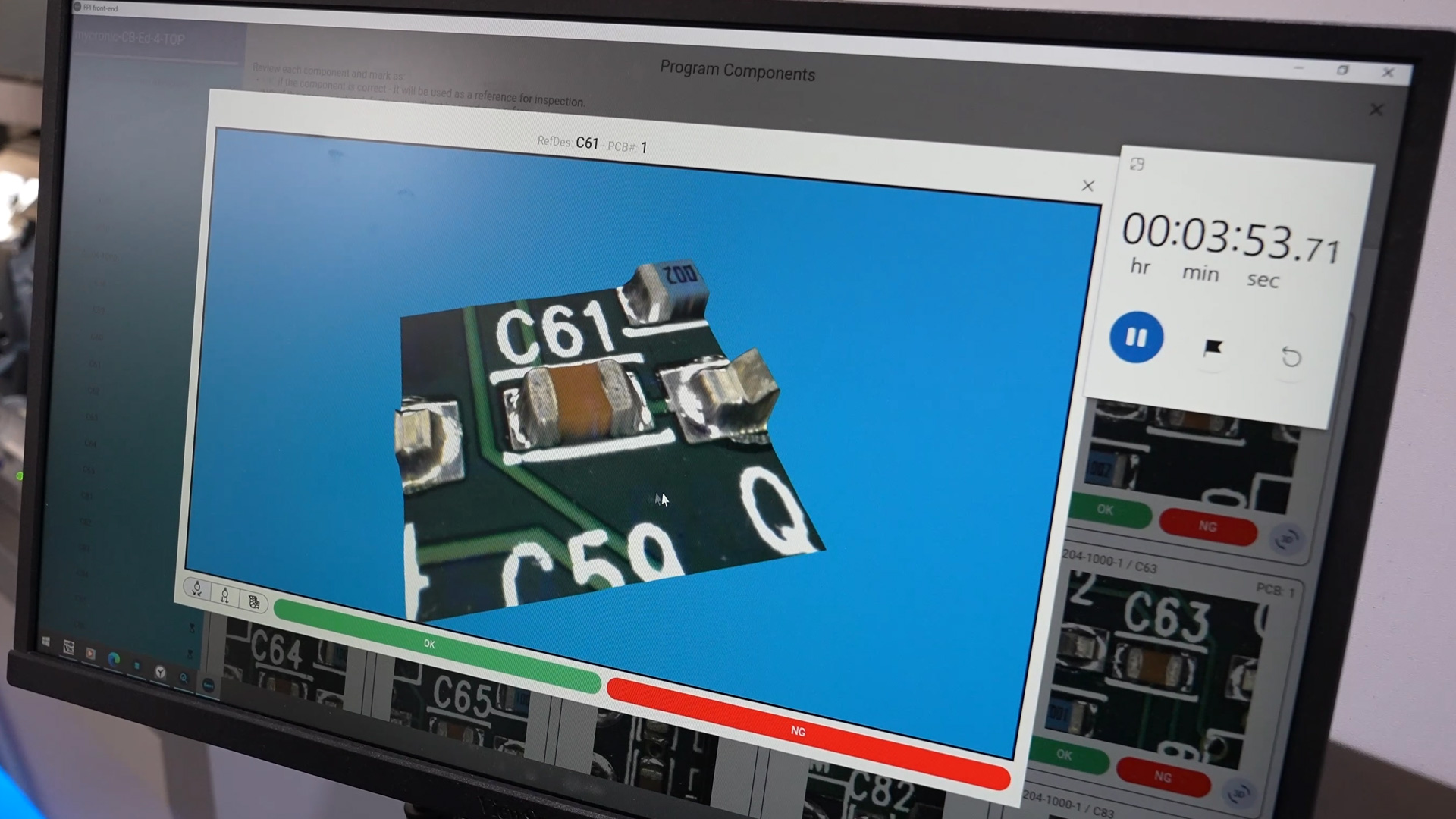

GenI software recognizes components with AI support

The GenI software uses neural networks to analyze the geometry and solder joints of the components. It automatically recognizes housing shapes, markings, lettering, and solder points. Based on the confirmed “OK” components, the system automatically adjusts the tolerances. After just a few minutes, a fully operational inspection program is available, which is verified in real time against CAD data. Defective components can be excluded during the learning process so that only qualified features are accepted as references. With each board inspected, the machine develops a more precise understanding of valid variants.

3D inspection based on real geometry measurement instead of image comparison

Unlike many conventional AOI systems, the MYPro I51z does not rely on pure image comparisons, but on genuine 3D measurement technology. The geometries of the components are measured in three dimensions and compared with the imported layout data. This method allows a much more precise assessment of the solder joints and avoids typical false alarms that often occur with conventional systems. In addition, 3D inspection provides valid data for process control and traceability—an important advantage for quality-critical applications.

A key feature of Mycronic's new AOI solution is its ability to self-optimize. Once a board has been inspected and the components confirmed as correct, the system remembers these characteristics. During subsequent inspections, the software recognizes known component states and can evaluate them in a more differentiated manner. This leads to a reduction in false alarms and speeds up the approval processes in production. The system continuously learns and automatically adapts to fluctuations in the manufacturing process – without any readjustment by an operator.

Integrated sensor technology and platform architecture for maximum process reliability

The MYPro I51z features high-precision sensor technology that not only contributes to component recognition but also to the accurate positioning of the boards within the machine. The platform automatically detects where the board is located and performs the inspection exactly at the specified coordinates. This precise control eliminates misalignment and ensures a smooth process. All relevant measurement data can be exported and further processed for QA purposes.

A key goal in the development of the MYPro I51z was to eliminate the need for AOI programmers as far as possible. The test program is set up automatically, based on existing data and a functional printed circuit board. This significantly reduces the personnel costs involved in quality assurance. This represents a real relief, both economically and organizationally, especially for companies with multiple SMT lines and high production volumes. The system is scalable, can be seamlessly integrated into existing production environments, and offers a comprehensive solution for the automatic inspection of complex assemblies.

Future-proof AOI technology with learning software

The MYPro I51z with GenI software marks a turning point in optical inspection. It combines artificial intelligence, 3D measurement technology, and sensor-based process control into a system that can be operated without special knowledge and at the same time delivers the highest inspection quality. For many electronics manufacturers, this opens up the possibility of taking quality assurance to a new level while reducing process costs and personnel capacities. Anyone looking for a future-proof, automated, and adaptive AOI solution will find a powerful answer in the MYPro I51z.