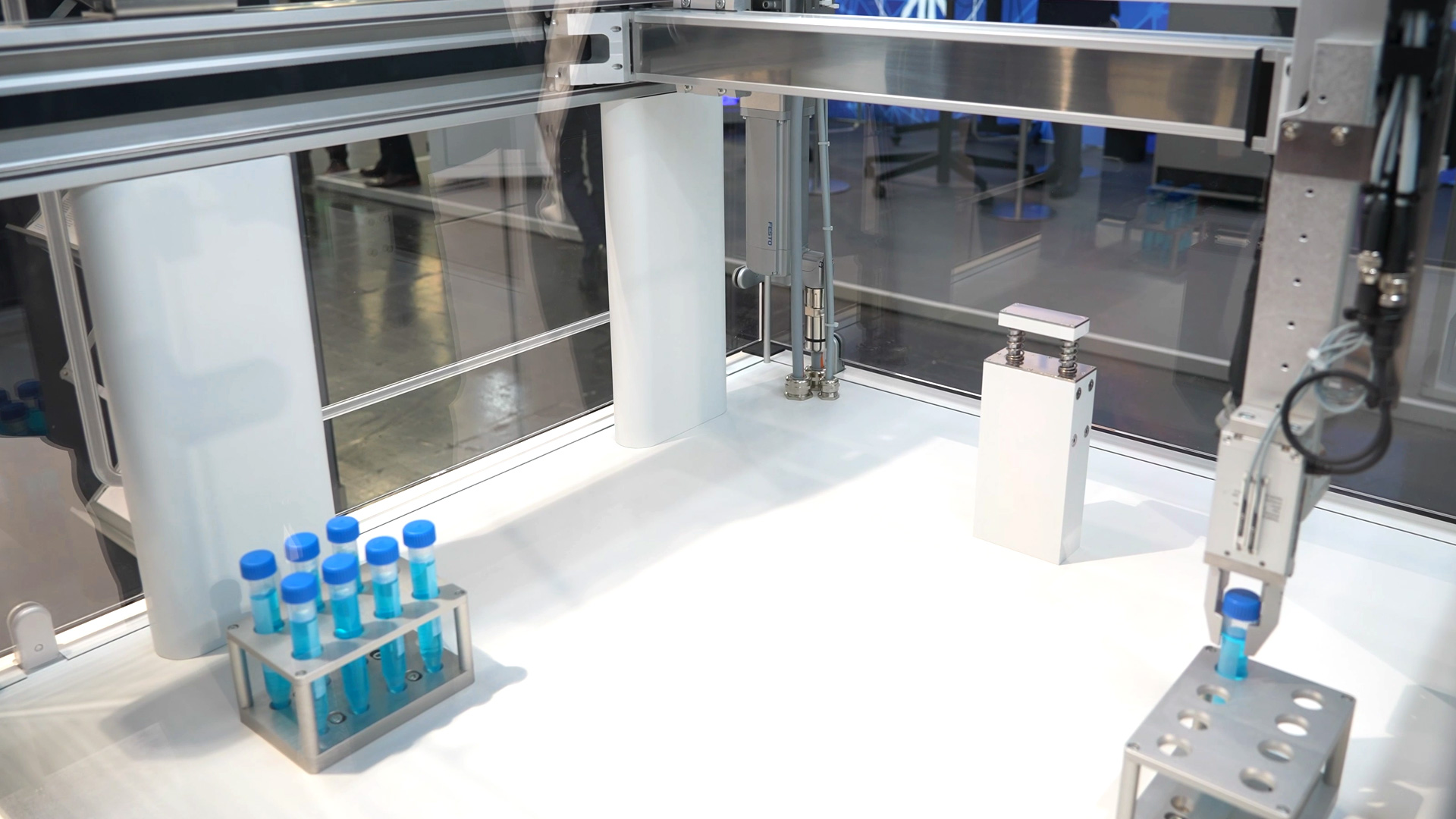

The EXCP Gantry System is presented as a new solution that enables high dynamics and precise motion sequences in confined spaces. The H-portal is designed for laboratory applications where fast positioning movements, stability, and an efficient working space are crucial. The solution shows how maximum performance can be achieved in a minimum of space without compromising on movement quality or process reliability, even when complex processes are running in parallel.

The design is based on an H-portal that enables highly dynamic movements and smooth speed changes in confined laboratory environments. Pick-and-place processes or precise handling steps can also be carried out where space is limited. At the same time, the overall system remains so compact that laboratory equipment remains easy to transport and can even be navigated through narrow doorways. This gives developers additional leeway in the design of their devices.

The central element is the combination of a small footprint and a large working space. The system takes the pressure off equipment manufacturers, as it hardly changes the installation space in the device and yet enables versatile movement sequences. Within this framework, different sample handling tasks, positioning processes, or recurring automation steps can be mapped without additional design effort. Every centimeter counts, especially in compact laboratory devices, which makes this approach particularly important.

For the first time, linear guides developed in-house are being used in combination with Festo axis systems to form a uniform gantry structure. The high level of vertical integration enables modular combinations of individual axes, while only two motors are required for xy alignment. The ELGD axes from the standard portfolio provide an economically attractive solution with high dynamics, robustness, and permanently reproducible precision, even with highly accelerated motion profiles.

The wide linear guide enables accelerations that many compact gantry systems cannot achieve. At the same time, positional accuracy remains stable and repeatable. For manufacturers of analytical equipment who need to implement processes in confined spaces, this creates a system that combines high dynamics, minimal installation space, and a flexible working area.