Electronic implants require materials that are both precise and biocompatible. LCP substrates are among the solutions that can be inserted directly into tissue without additional sheaths or encapsulations. A technology portfolio that combines biocompatibility, miniaturization, and robust precious metal conductor tracks—an area that is currently gaining in relevance as diagnostics increasingly operate on a continuous basis. Several applications demonstrate how flexible structures and precious metal coatings can be formed into sensor platforms that follow anatomical conditions and deliver consistently reliable measurements.

At Compamed, it becomes clear that LCP as a thermoplastic is taking on completely new tasks in medical technology. The material base is used where conventional rigid laminate structures or polyimide substrates reach their limits. LCP enables substrates that can remain in the body without additional coating layers while still remaining stable and precise.

Instead of copper, which is considered potentially toxic in the body, gold and platinum are used. These precious metals can be applied in fine structures and form conductive tracks that can remain permanently in the tissue. They make the substrates a functional part of the implant, not just a support structure.

LCP enables flexible circuit layers that can adapt to anatomical shapes. This flexibility creates the conditions for implants that are barely noticeable and yet work in direct contact with tissue. As a result, the sensor technology can be designed to be significantly smaller than in classic implants with housings.

A key example is continuous glucose monitoring. Such sensors require a permanent connection to the tissue, as measurements take place without interruption. LCP substrates create precisely this connection: they remain in place permanently and transmit values without the patient having to actively intervene.

In addition to diabetes, the technology is also suitable for chronic pain conditions and other medical indications where tissue contact and long-term data are crucial. The range of possible applications is wide, as any form of continuous sensing benefits from flexible, biocompatible structures. Since the substrate itself can be implanted, many steps that are necessary with conventional implants are eliminated. The procedures are smaller, the stress is reduced, and the sensors deliver stable values over longer periods of time.

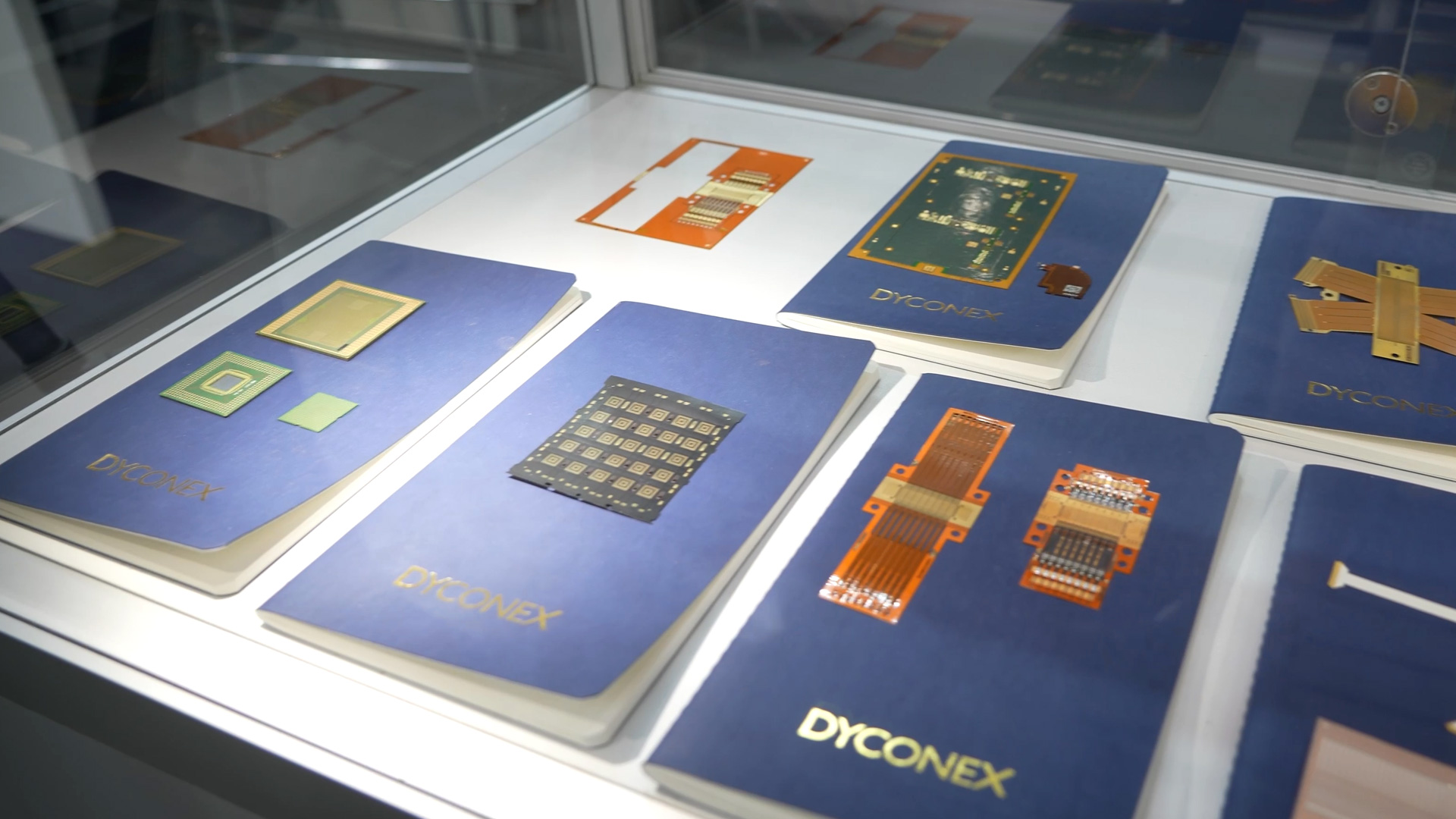

Dyconex has more than two decades of experience in working with precious metal conductor tracks. This extensive manufacturing expertise is reflected in reproducible structures, durable circuits, and process reliability, which is crucial in this field of application. The combination of material knowledge and miniaturized technology forms the basis for implantable sensor solutions that work reliably over the long term.