The trade fair presentation at Compamed shows how ideas for infusion bags, blood bags, catheter systems, and bioprocess bags are turned into complete production lines. Development always starts with the product and leads through precisely defined processes to durable machines that operate reliably for many years. This combines medical requirements with industrial vertical integration.

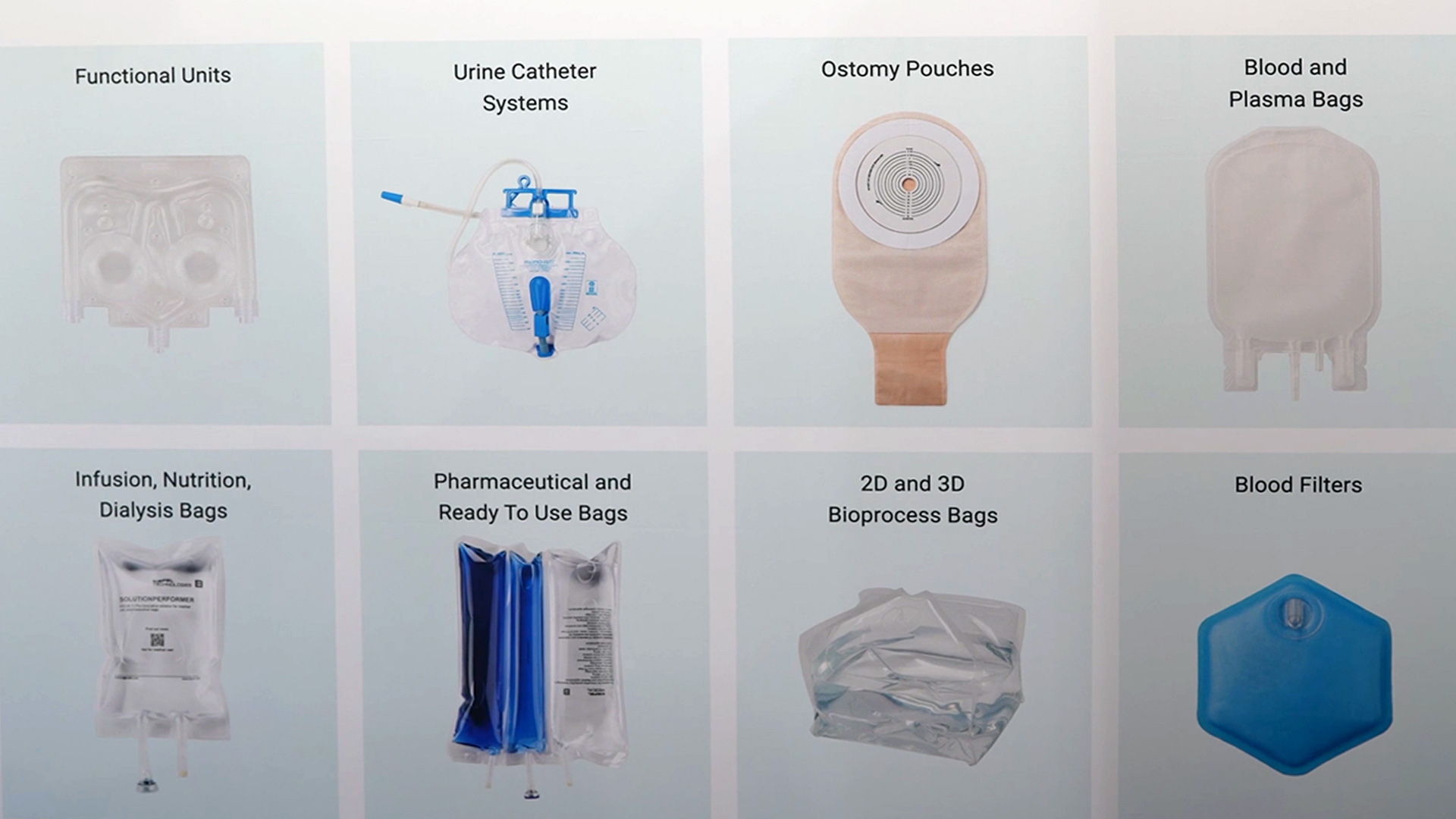

The starting point is always the final medical product, which serves as the basis for all further steps. Infusion bags, blood bags, ostomy solutions, catheters, and custom-made products form a broad spectrum with significantly different requirements. What they all have in common is flexible packaging as the technical core component. Additional functional units are often added, such as integrated valves, pumps, or sensors, which simplify everyday clinical use or enable more precise dosing.

In this early development phase, material composition, weldability, barrier properties, and interfaces are determined. This is not only about the final function, but also about which process steps are technically feasible. Only when the product profile has been fully defined can the further production process be determined. This initial step is crucial because every property—from film thickness to port geometry—has an influence on the subsequent machine solution.

In the field of infusion and pharmaceutical bags, barrier properties, port systems, and filling solutions are the main focus. Products containing active ingredients require additional material layers that ensure chemical resistance, light protection, or diffusion barriers. Each of these requirements influences the subsequent process control and the design of the system. Once the products have been defined, manufacturing processes are developed that enable high volumes to be produced reliably over long periods of time. Welding processes, material feeds, and handling steps are coordinated in such a way that they remain reproducible and also meet demanding quality specifications. Only when this process is in place does the technical implementation of the machine begin.

The machine solution is developed step by step from the defined process. The design follows the previously defined processes and is designed to operate stably over very long operating phases. Systems are commissioned, tested, delivered, and then maintained throughout their life cycle. Tool changes enable the implementation of further product variants without changing the basic machine.

In the transfusion sector, bag sets are produced that connect several components. These include solutions for plasma separation, secure connection systems, and material structures that can withstand the mechanical stresses of everyday clinical use. The manufacture of such bags requires precisely coordinated processes across several production steps.

Due to their diversity, catheters are a product area in their own right. They require customized geometric shapes, stable connection points, and both primary and secondary packaging. The combination of shaping, filling, and packaging is created in well-thought-out process chains that are tailored to the respective medical requirements.

Large-volume flexible containers are becoming increasingly important in biopharmaceutical production. Bioprocess bags replace rigid stainless steel containers, eliminate cleaning costs, and prevent cross-contamination. Their single-use nature significantly reduces the consumption of cleaning media. Machines for three-dimensional bag structures expand the production spectrum in this segment.

There is a wide variety of options in the ostomy sector. Open, closed, and convex bags are produced on highly flexible systems that can handle numerous products. Tool changes allow for additional variants without having to adapt the entire infrastructure. The product examples show typical market solutions, while customer-specific developments remain inaccessible for confidentiality reasons.

Multi-chamber bags allow different solutions to be stored separately. They are only connected to each other shortly before use by means of roller presses. This allows amino acids, lipids, electrolytes, vitamins, and trace elements to be safely combined in a single dose. Material layers, weld seams, and chamber divisions must therefore be designed with particular precision. Some of the developments can be shown at trade fairs—such as standard infusion bags, dialysis bags, or selected ostomy products. Many other solutions are created on behalf of individual customers and are subject to contractual confidentiality. This mixture of openly accessible examples and non-visible special projects characterizes the field of flexible medical packaging and the associated machine solutions from Kiefel.