Digitalization is fundamentally changing logistics – and S2data is one of the companies actively shaping this change. With a powerful software solution for the holistic optimization of transport processes, the young company from Graz is enabling a new level of quality in supply chain management. The aim is to reduce transports, make better use of resources, and measurably reduce the industry's ecological footprint.

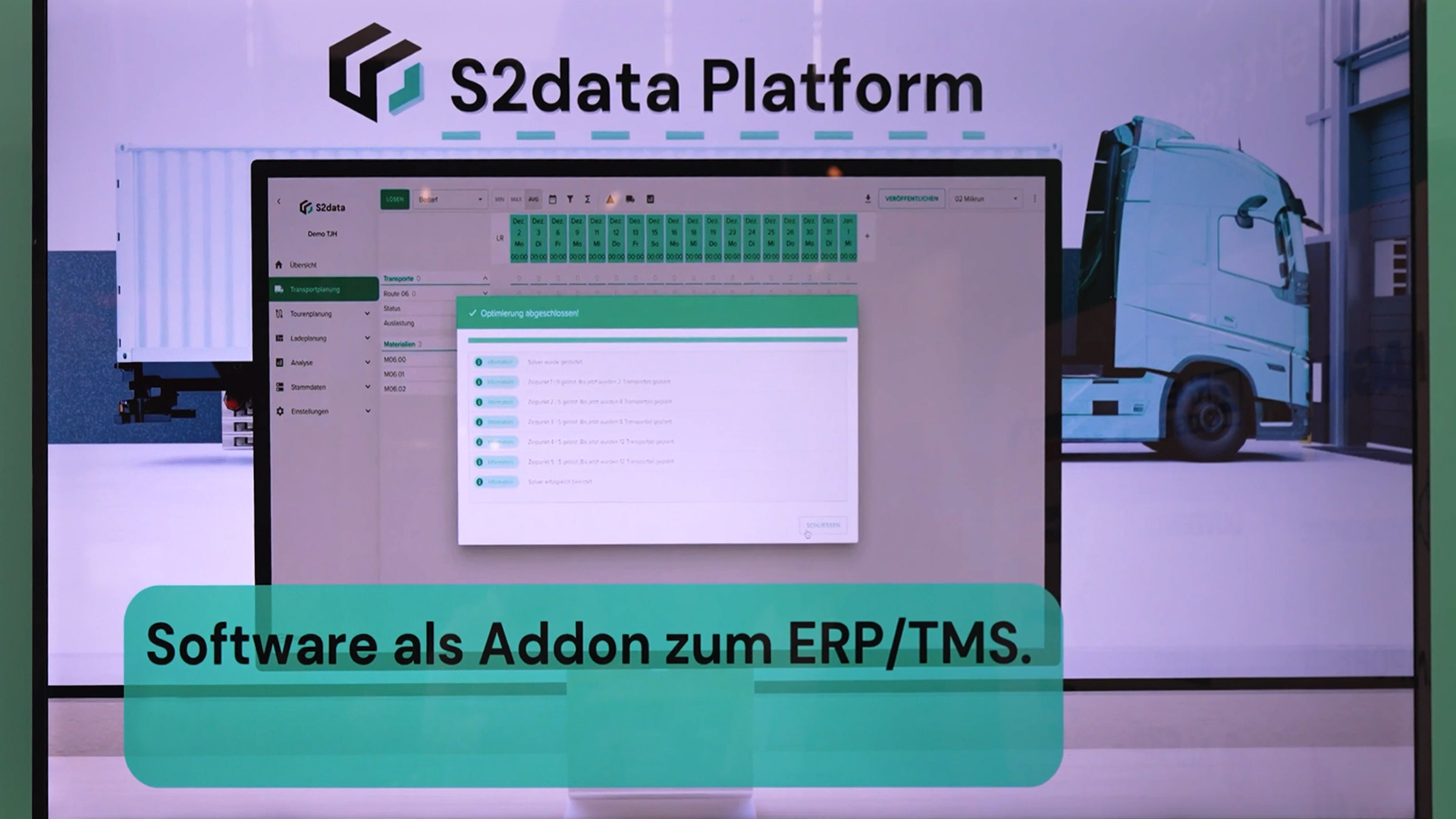

S2data relies on intelligent algorithms that evaluate all relevant data along the supply chain – from orders and packaging dimensions to 3D loading space planning. The software connects directly to existing ERP or TMS systems, analyzes transport orders, and then automatically plans optimized routes. Weight, loading meters, axle loads, and other logistical parameters are taken into account to maximize the utilization of transport resources.

A central approach is to make full use of every available centimeter of cargo space. S2data consolidates loads, bundles transports, and creates better transport plans on this basis – for shippers and carriers alike. This intelligent bundling not only saves trips, but also reduces the number of drivers required.

The solution is suitable for both short-term and long-term planning. While some customers need to adjust their requirements on an hourly basis, others – such as those in the industrial sector – can plan weeks in advance. The software already helps to identify which goods can be transported together, even if they are not required until later dates.

One goal of automated dispatching is to efficiently bundle as many orders as possible into as few trips as possible. Forward-looking planning saves both personnel and resources without compromising delivery reliability. The flexible planning approach makes the software particularly attractive for dynamic market conditions.

A particularly important area of application is the automotive industry. This is where S2data implemented its first projects and, according to its own figures, can save up to 20 percent of transport costs in the inbound sector – among other things through targeted planning of FTLs and milk runs. OEMs and suppliers benefit from optimized transport chains with better load space utilization.

Large logistics service providers such as Duvenbeck and Rhenus also use the software to continuously improve their processes. The application is not limited to specific company sizes: S2data supports both smaller suppliers with few partners and international corporations with complex delivery networks.

S2data's business model is scalable: those who have fewer transports pay less, while those who have greater requirements benefit from greater optimization. Even companies with in-house IT expertise are opting for the software-as-a-service solution, as the cost of in-house development and support often exceeds the benefits.

Thanks to proven implementations in 16 countries, the solution can be quickly integrated into existing processes. Its international use underscores the scalability and practical benefits of the system, regardless of the size or industry of the respective customer.

Many companies are currently facing fundamental changes, such as SAP migrations or the restructuring of logistics processes. The more digital these processes are, the greater the potential for optimization. This is exactly where S2data comes in: with cloud-based software that reduces the burden on operational activities and creates new scope for efficiency.

The goal remains clear: every truck saved means CO₂ saved. Through more precise planning, better utilization, and the elimination of unnecessary empty runs, the solution makes a measurable contribution to reducing the ecological footprint. This makes logistics not only more economical, but also more sustainable.