Logistikbude offers a digital solution for load carrier management in logistics, which for the first time provides end-to-end, cross-company digital transparency for pallets, crates, and mesh boxes. Based on the approach of digital transparency for pallets, crates, and mesh boxes through Logistikbude, the software combines process understanding, automation, and system integration into a practical solution. In this way, Logistikbude creates measurable efficiency, clear responsibilities, and a reliable database for modern logistics processes.

The name Logistikbude says it all. “Logistics” stands for the team's professional background: the four founders – now joined by a larger team – come from the research department at the Fraunhofer Institute for Material Flow and Logistics IML in Dortmund. There, they spent years working on customized solutions for managing packaging materials, loading aids, and packaging. The word “Bude” refers to the company culture: down-to-earth, approachable, and solution-oriented, with a dash of Ruhr region mentality.

Instead of rigid systems, the software is based on real processes. Experience gained from numerous customer projects has been directly incorporated into the current product. The aim was to create a flexible system that can be easily adapted to existing processes – not the other way around.

Whether Euro pallets, mesh boxes or plastic crates – modern logistics would be unthinkable without these transport aids. Nevertheless, their management is often neglected. While everything revolves around the so-called “full goods,” empty load carriers often remain invisible. Yet they not only represent a considerable material value, but are also a prerequisite for functioning supply chains.

If it is not clearly documented where which load carriers are located, who uses them, or who they belong to, deficits quickly arise: missing items, repeat purchases, and production stoppages are the result. This is exactly where Logistikbude comes in – with a platform that creates overviews, documents exchange processes, and clearly maps responsibilities.

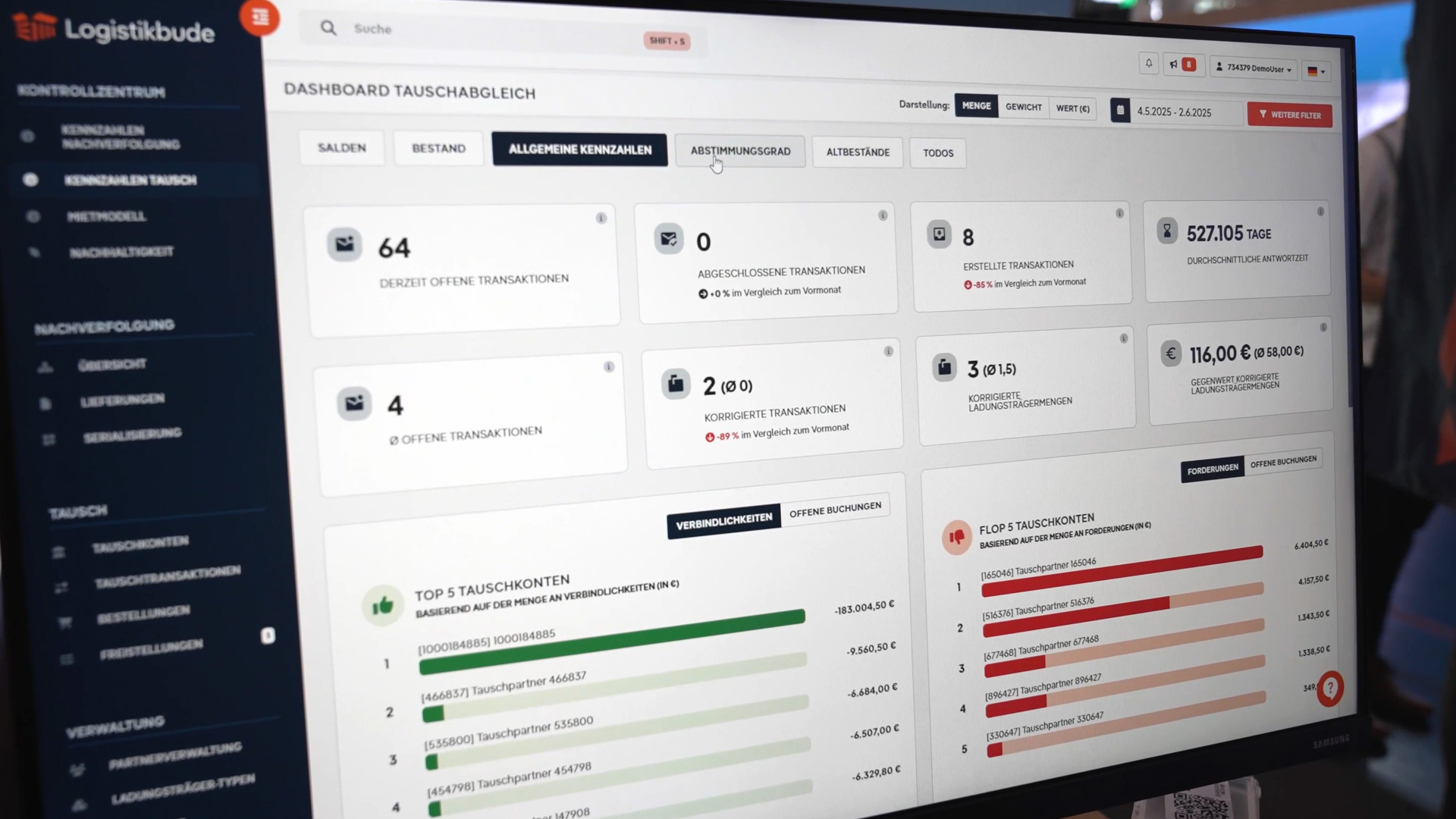

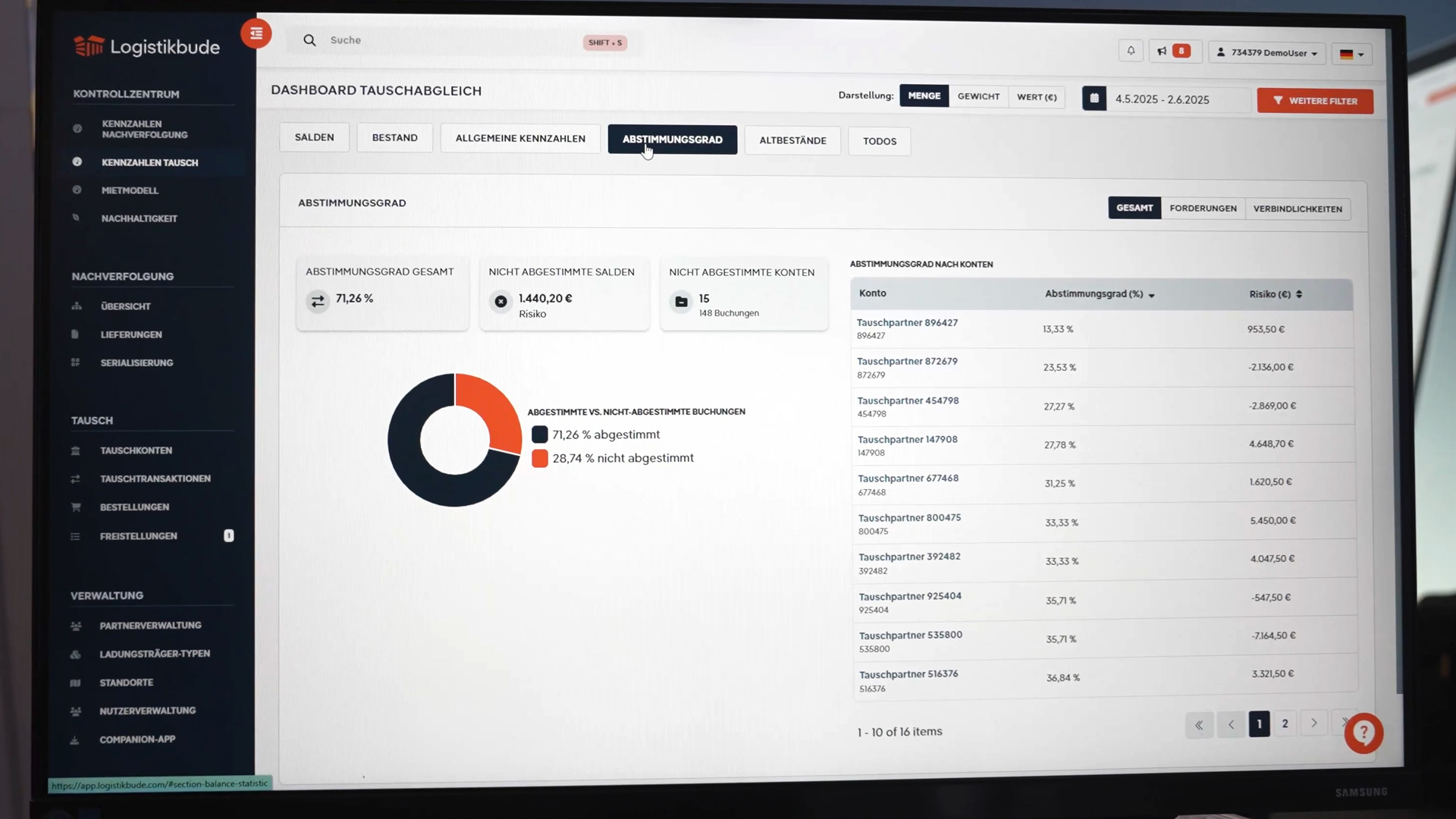

At the heart of the software is automated management of load carrier movements. The first step is to track where which units are located and which exchange partners are involved in which movements. Customers receive key figures on the degree of coordination with partners and can evaluate processes.

Where manual bookings were previously necessary – for example, in so-called pallet departments – the software reduces the workload through digital workflows. The application can either be used as a greenfield solution to completely replace Excel lists or connected to existing systems such as TMS, WMS, or SAP via interfaces. This creates a continuous flow of information along the supply chain. Existing data is fed into the system and made usable. The result: real-time transparency in operations and the basis for step-by-step automation.

Not every carrier is equally valuable – and not every carrier needs the same technology. For high-value transport racks such as window racks, which can cost four-figure sums, Logistikbude works with sensor solutions in cooperation with partners such as Bosch and Deutsche Telekom. This allows the location of each individual carrier to be tracked live.

For less expensive load carriers such as Euro pallets, the focus is on the exchange process. The system documents the quantities exchanged between the partners, thus ensuring that no inventory is “lost.” RFID and BLE technologies are also available. The specific variant used is always determined based on the specific use case and in close consultation with the customer.

The software is suitable for all players involved with load carriers: manufacturing companies, logistics service providers, medium-sized freight forwarders, and retailers. Even a glance at a vegetable counter shows how widespread the issue is: there are often green or black reusable crates that can be managed via the system.

Currently, more than 30 companies are already actively working with the platform. Its use ranges from simple entry-level applications to integration into existing IT structures. The modular design allows the solution to be rolled out step by step – from the visibility of individual inventories to complete process automation.

The cost of the software is based on the annual load carrier throughput. During the initial consultation, the team analyzes how many carriers are in use, what movements take place, and how much effort is required for administration and coordination. Based on this, a suitable package is put together that leaves enough buffer to avoid reaching limits even as the business grows.

The solution is offered as Software-as-a-Service (SaaS) and is therefore flexibly scalable. The aim is to make it as easy and economical to use as possible – so that companies can organize their load carrier management not only more efficiently, but also more sustainably.