The Cologne University of Applied Sciences spin-off Detection-X brings AI directly into industrial applications - without the need for programming knowledge. The software platform allows complex recognition models to be created using drag-and-drop and operated locally. It was developed out of the need to bundle all steps from data annotation to productive use in a standardized, intuitive environment.

Detection-X emerged from the Laboratory for Applied Artificial Intelligence at TH Köln. AI technologies were developed there in numerous projects, tested in specific use cases and brought to market maturity. This revealed a recurring challenge: many existing systems in the field of object recognition are fragmented - they require several software solutions, specific expertise and external specialist personnel.

The idea behind Detection-X was to combine all the essential steps in one application and make it accessible to users without a data science background.

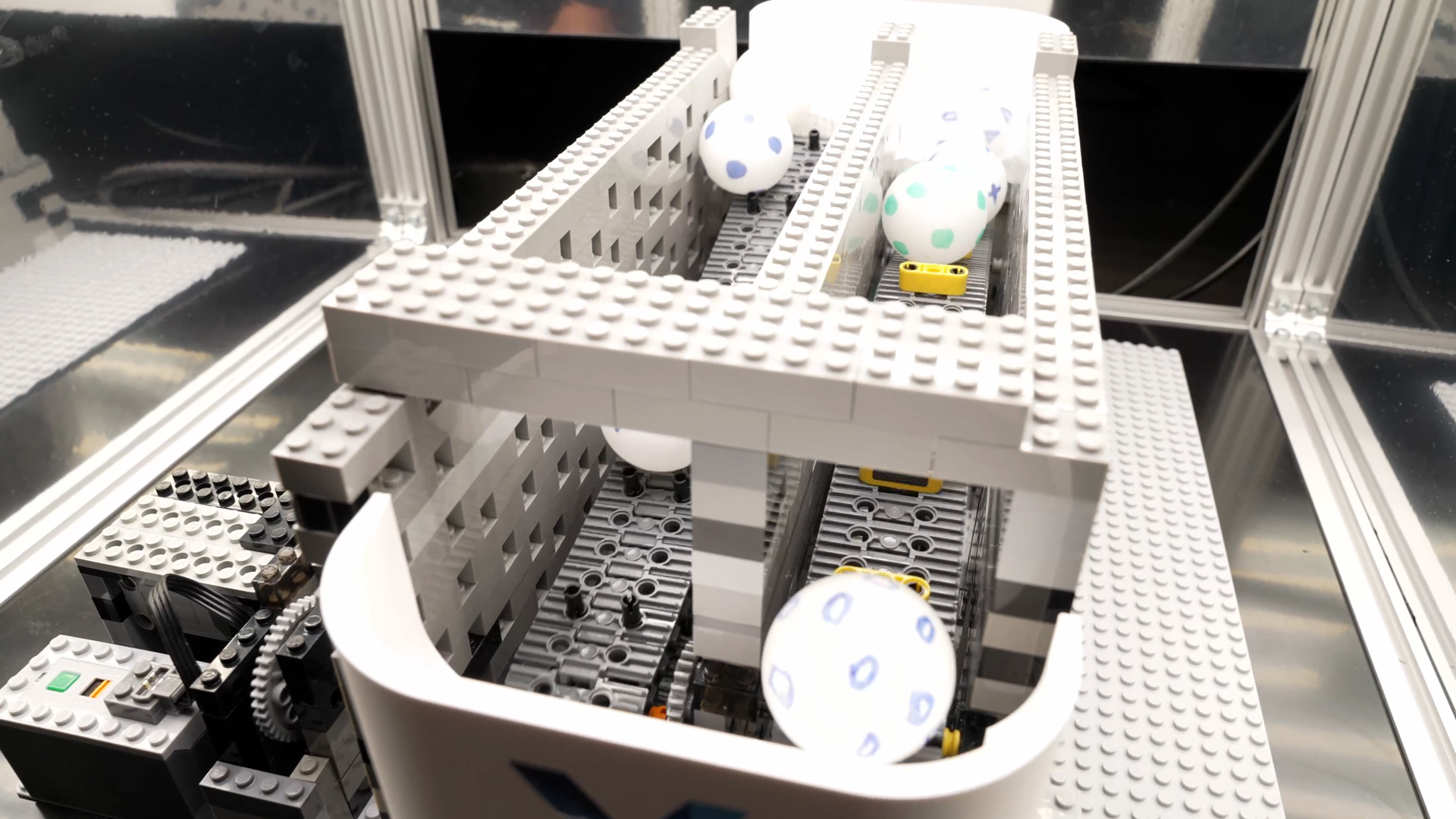

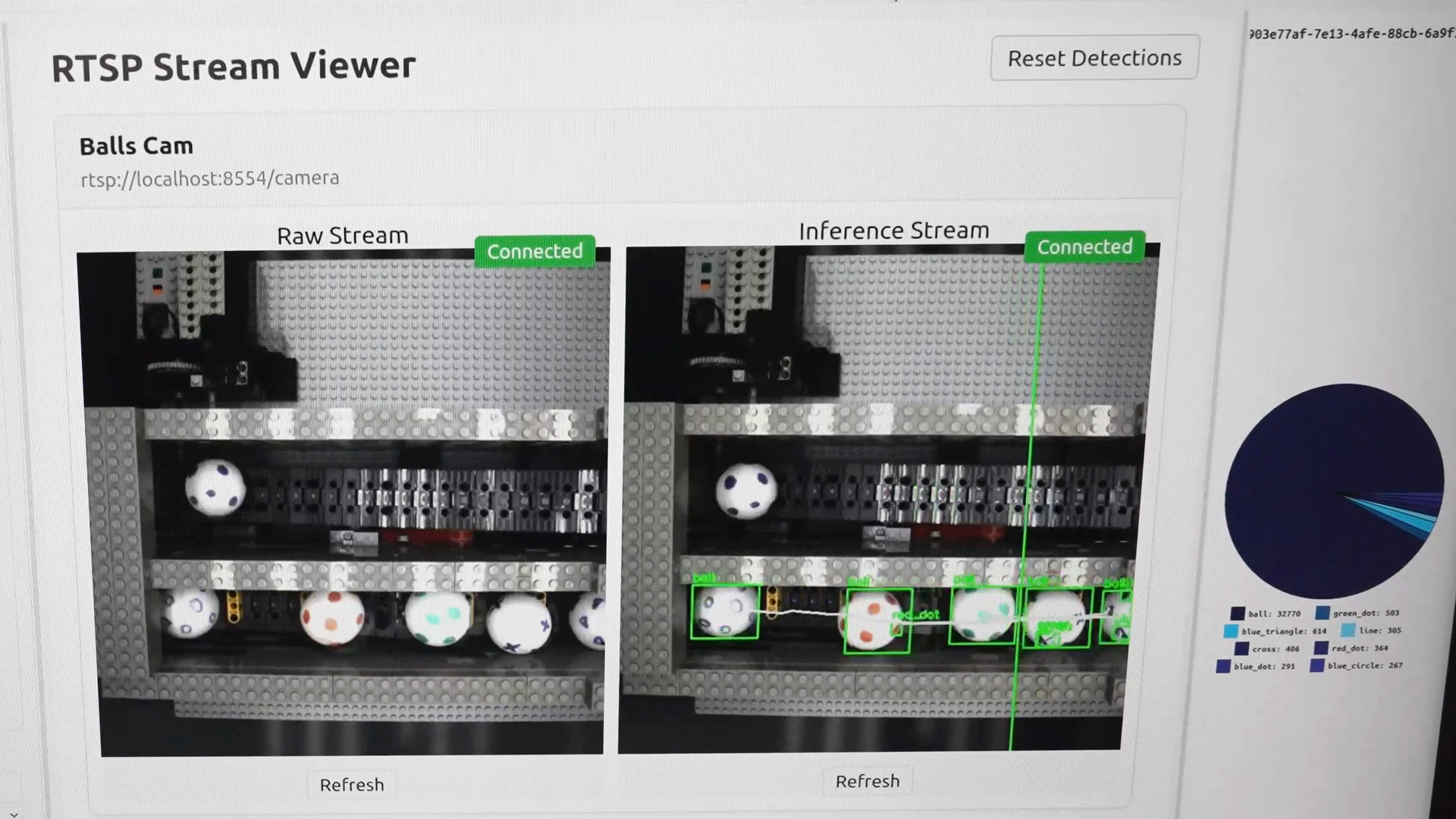

At the heart of the solution is a visual programming environment that can be used to logically link even complex AI models. Table tennis balls are recognized and analyzed on a demonstrator with a small conveyor belt - one model recognizes the balls, another identifies the painted objects.

Such modular systems can be combined into multi-stage recognition processes. The special feature: The entire logic can be represented graphically. The target group are specialists from industry, such as engineers or logisticians, who have no traditional programming experience.

A specific use case can be found at a large tire manufacturer. The “Stack-Scan” software is used there to automatically record stacks of goods. The solution counts products, reads barcodes, compares information and thus supports final quality control.

It is based on image processing models such as image segmentation, object recognition and text recognition (OCR), which are combined in a logical chain - without external programming, solely via the visual user interface.

The advantage of Detection-X lies in the low barrier to entry. Companies do not need their own data scientists, but can set up and operate AI applications internally. Many tasks can be automated, especially in logistics: detecting damage, reading out information or monitoring processes.

In one example, the system recognizes when a traffic jam forms on a conveyor belt - a task that was previously performed visually by an employee. With the software, a corresponding model can report independently as soon as a backlog forms.

For the developers, the focus is on a fundamental idea: AI is the first technology that is able to simulate human behavior. In this case, it is about visual perception - an area that is central to many industrial processes.

Humans are visual beings, and it is precisely this aspect that the software addresses. Whether goods carrier tracking, barcode analysis or process monitoring - all tasks associated with vision and recognition can be digitized with the solution.

Detection-X creates a practical approach to AI - without technical barriers. Thanks to the integration of all process steps and its ease of use, the platform enables companies to create their own detection models and use them productively. For medium-sized companies in particular, this opens up the opportunity to use AI specifically for their requirements - efficiently, comprehensibly and independently of external IT personnel.