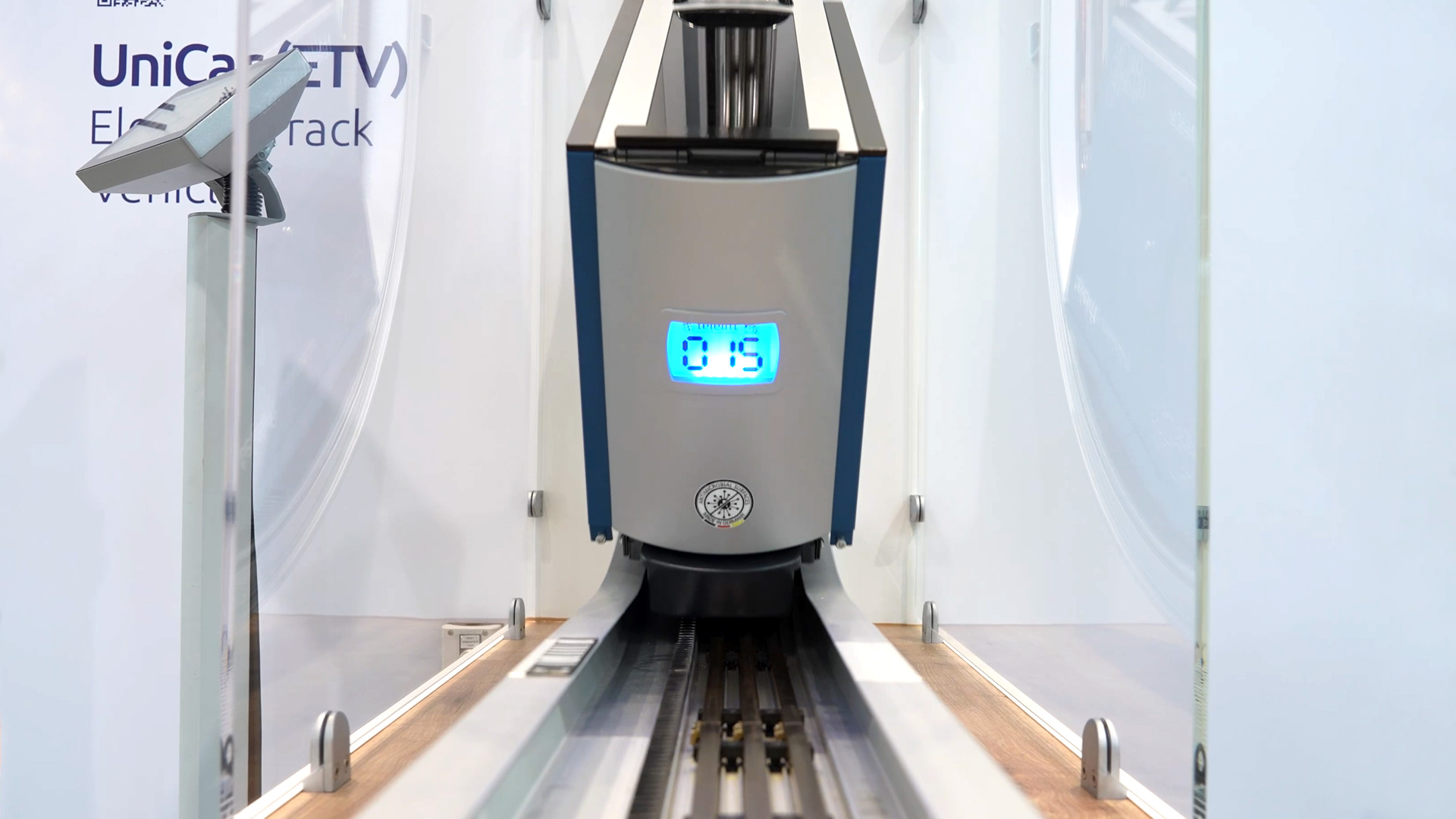

At this year's MEDICA, the focus is on a system that is set to fundamentally change intra-hospital transport: the complete solution for hospital logistics with the UniCar system at its core. The combination of modular components, versatile installation options, and a three-dimensional rail concept enables goods transport that can cover large parts of daily operations. Particularly interesting is its ability to carry out transport automatically, in a space-saving manner, and almost without interruption.

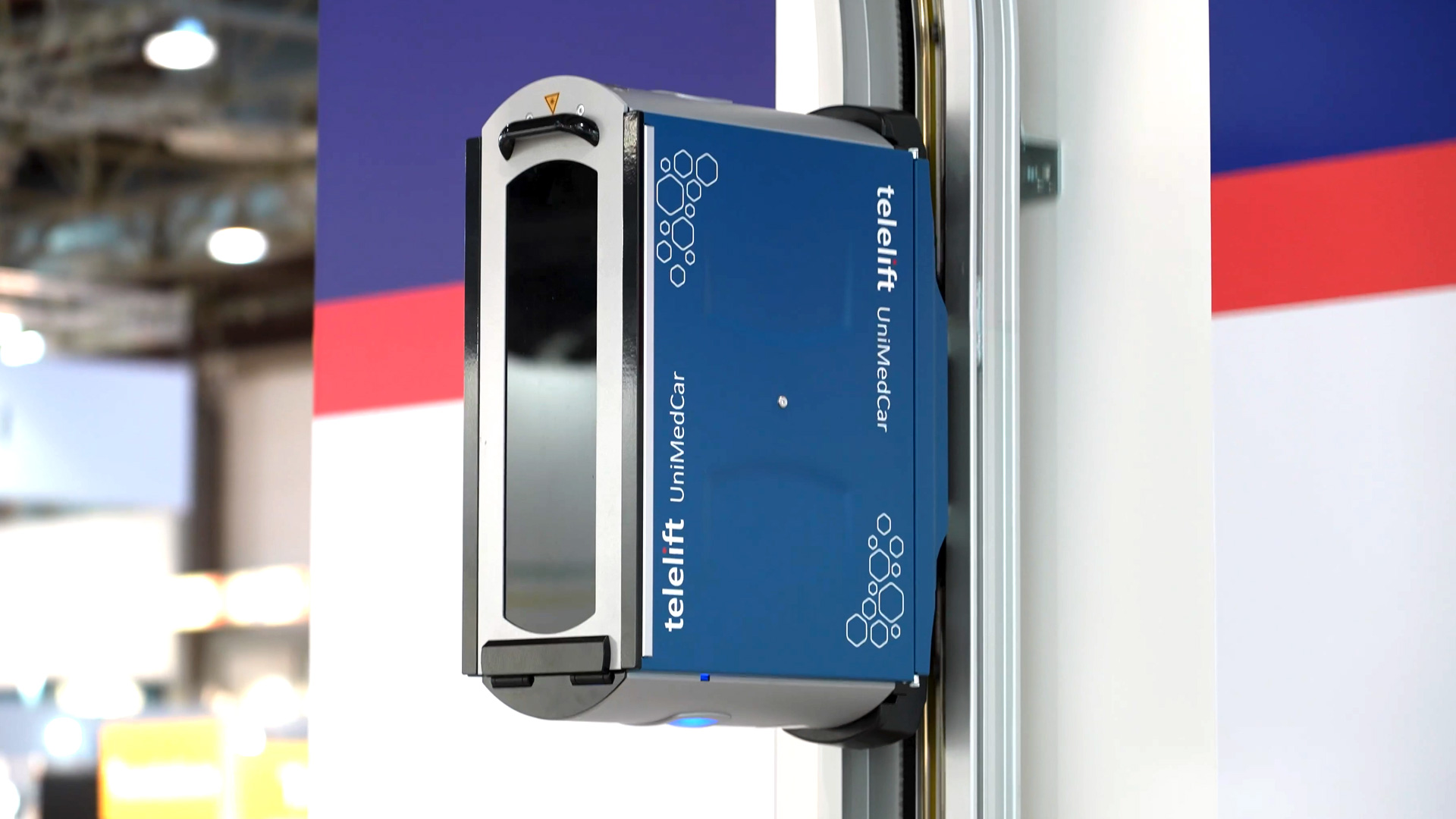

The UniCar system is based on a rail-bound transport technology that can be installed horizontally, vertically, and in freely combinable axes. The modular design allows for adaptation to both existing and new buildings. A key feature is its suspended operation under the ceiling, which keeps the floor free and avoids bottlenecks in corridors. The system thus integrates into processes without blocking spatial resources.

Typical transport goods range from laboratory samples and medications to daily consumables such as gloves or disposable sterile goods. As a rule of thumb, anything that fits into two shoe boxes is suitable for the system. For larger goods, additional solutions from the same product range are available, covering all relevant types of transport in a hospital.

Hospitals that want to demonstrate their technical openness deliberately leave the system visible – for example, along certain visitor areas. Others opt for concealed installation under suspended ceilings, which is very common in Germany. Both variants offer identical functionality. Small systems are also possible, for example for fast transport from the emergency room to the laboratory. In large clinics, on the other hand, there are routes many kilometers long on which numerous vehicles are in operation at the same time.

Since the vehicles operate in stationary mode, in vertical transport, and in suspended mode, the transported goods must be kept stable. There are two approaches to this: padded inserts or a swivel container that keeps the load horizontal at all times using a counterweight. The system is designed for up to fifteen kilograms, and the vehicles reach speeds of up to 0.8 meters per second – sufficient for fast yet safe transport.

Assembly, quality assurance, and commissioning are carried out entirely at the Maisach site near Munich. Quality standards are a central component of the system, as intra-hospital transport processes must function reliably at all times. Installation is also usually carried out by our own team to ensure a seamless transition from setup to operation.