Heidenhain is presenting the TNC7 in various versions at EMO with the new generation of its motion controllers. The portfolio is complemented by the vTNC7, an innovative programming system that generates NC programs from 3D models. The combination of proven operating elements and new, intuitive functions underscores the company's commitment to making manufacturing processes even safer, more efficient, and more intelligent.

At its booth, Heidenhain will be showcasing the TNC7 in all available configurations – from 16 inches to 19 inches to the largest version with 24 inches. The operating panel combines a full-size keyboard with a modern touch concept and the new OC310 override controller. This makes it easier and safer to run NC programs by setting breakpoints directly in the user interface. Vibration signals indicate when breakpoints have been reached, allowing the operator to keep their hand on the controller and their eyes on the work area. The intuitive full-touch operating concept in particular highlights Heidenhain's focus on ergonomics and precision.

The Override Controller OC310 replaces the classic potentiometers with a haptic, vibration-supported control element. The system signals when breakpoints are reached and ensures that programs can be continued in a controlled and efficient manner. For the user, this means a noticeable improvement in safety, ergonomics, and efficiency when running new programs. In addition, the new black potentiometer with a clear 100% detent provides quick orientation, even without visual control. This results in increased safety and speed, especially during longer run-in processes, which directly increases productivity in production.

Despite the numerous innovations, Heidenhain attaches great importance to continuity. Users will find the key assignments of familiar controls, such as the iTNC 530, in the same familiar locations on the TNC7. This means that long-established operating routines remain unchanged, while new functions such as the full touch concept make operation even easier. The combination of familiar and innovative features makes the transition to the TNC7 particularly user-friendly and reduces training times.

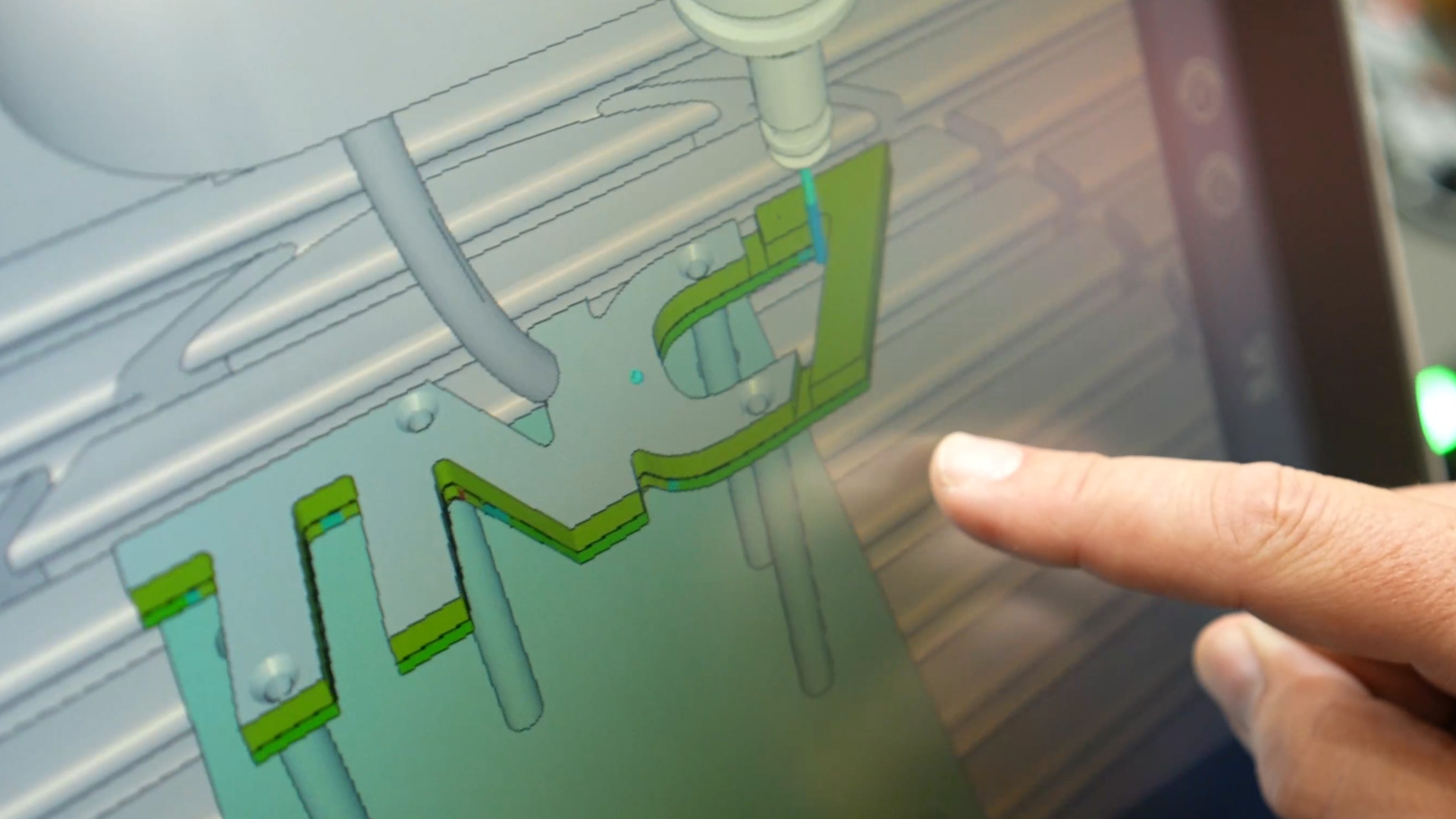

In addition to the controls, Heidenhain is presenting the vTNC7, a powerful programming system. This system quickly generates NC programs for 2.5D components from 3D models. Feature-based programming ensures easy handling, while plain text is generated in the background. This makes the programs compatible with older path control systems. A plain-text converter also enables output for existing systems, allowing the vTNC7 to bridge the gap between the latest developments and proven controls. The system saves time in work preparation and helps companies flexibly adapt their manufacturing processes to current requirements.

With TNC7 and vTNC7, Heidenhain is consistently focusing on a combination of ergonomic operation, proven plain-language programming, and modern features for smart manufacturing. The motto “Empower Manufacturing” is made tangible by the solutions presented—from control technology to the programming environment.