At EMO 2025 in Hanover, Grob will present a wide range of machines that address current developments in the industry. The focus will be on compact milling and turning centers as well as large-format solutions for automotive production, where lightweight construction and CO₂ reduction play a central role.

Grob is presenting the single-spindle, four-axis G400 in Europe for the first time. The machine expands the portfolio of precision machining solutions and is aimed at users who require high productivity in a compact space. With flexible machining and an optimized concept, the G400 primarily addresses the need for efficient, modern manufacturing processes.

In addition to the G400, Grob is presenting a milling-turning machine with hydraulic clamping. It combines milling and turning in one workspace, enabling complex machining operations with greater efficiency. The range is complemented by the GMP300, a system for additive manufacturing. Grob is thus emphasizing that, in addition to classic machining, future technologies such as 3D metal printing also play an important role in its portfolio.

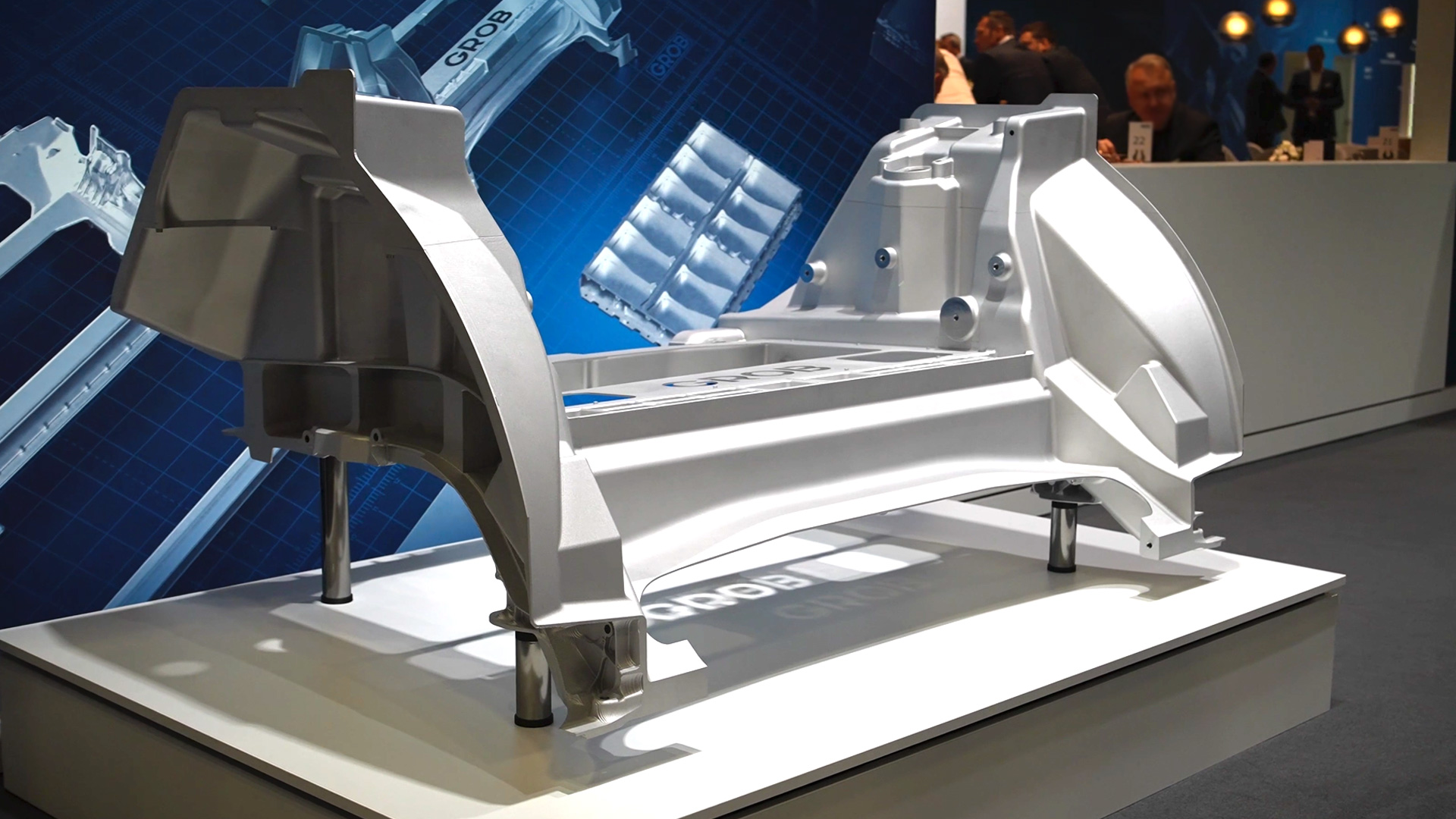

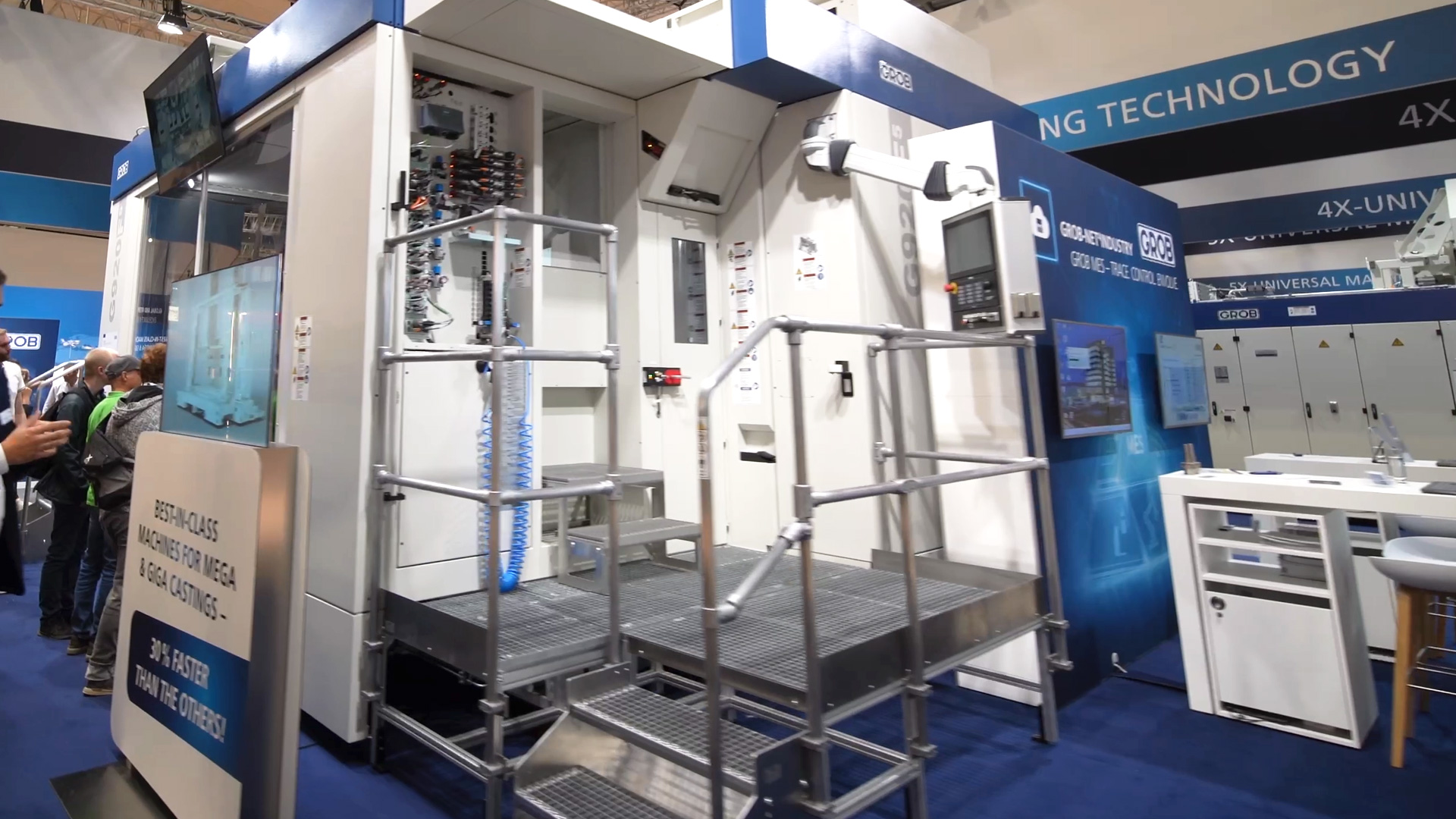

The focus of the trade fair is on the G920F5 – the largest machine currently in Grob's range. It was developed specifically for mega and giga castings, which are becoming increasingly important in the automotive industry due to the trend toward lightweight construction and CO₂ reduction. The machine sets standards in terms of dynamics, stability, and machining quality. The horizontal spindle concept gives it high rigidity, while the optimized design ensures optimum performance and shorter cycle times.

A particular advantage of the G920F5 is the option of twin-spindle machining. This allows up to 90 percent of processes to be performed twice – either simultaneously on two components or synchronously on one workpiece. This significantly increases productivity and reduces throughput times. Customers benefit from a machine that combines speed and precision.

Grob emphasizes that development is not complete with the current generation. The company is already working on an advanced version that will offer even greater dynamics and a larger working space. The goal is to machine two components simultaneously in the working space, thereby further increasing productivity. Grob is thus responding to the growing demands of international markets and focusing on sustainable further development.