At the trade fair, Siemens is presenting the MTR Machine Tool Robot, a solution that combines robot mechanics and control technology to create an industrial-grade machining unit. This innovative approach opens up new possibilities in industries such as aircraft construction and automotive, where maximum precision is crucial for large machining surfaces.

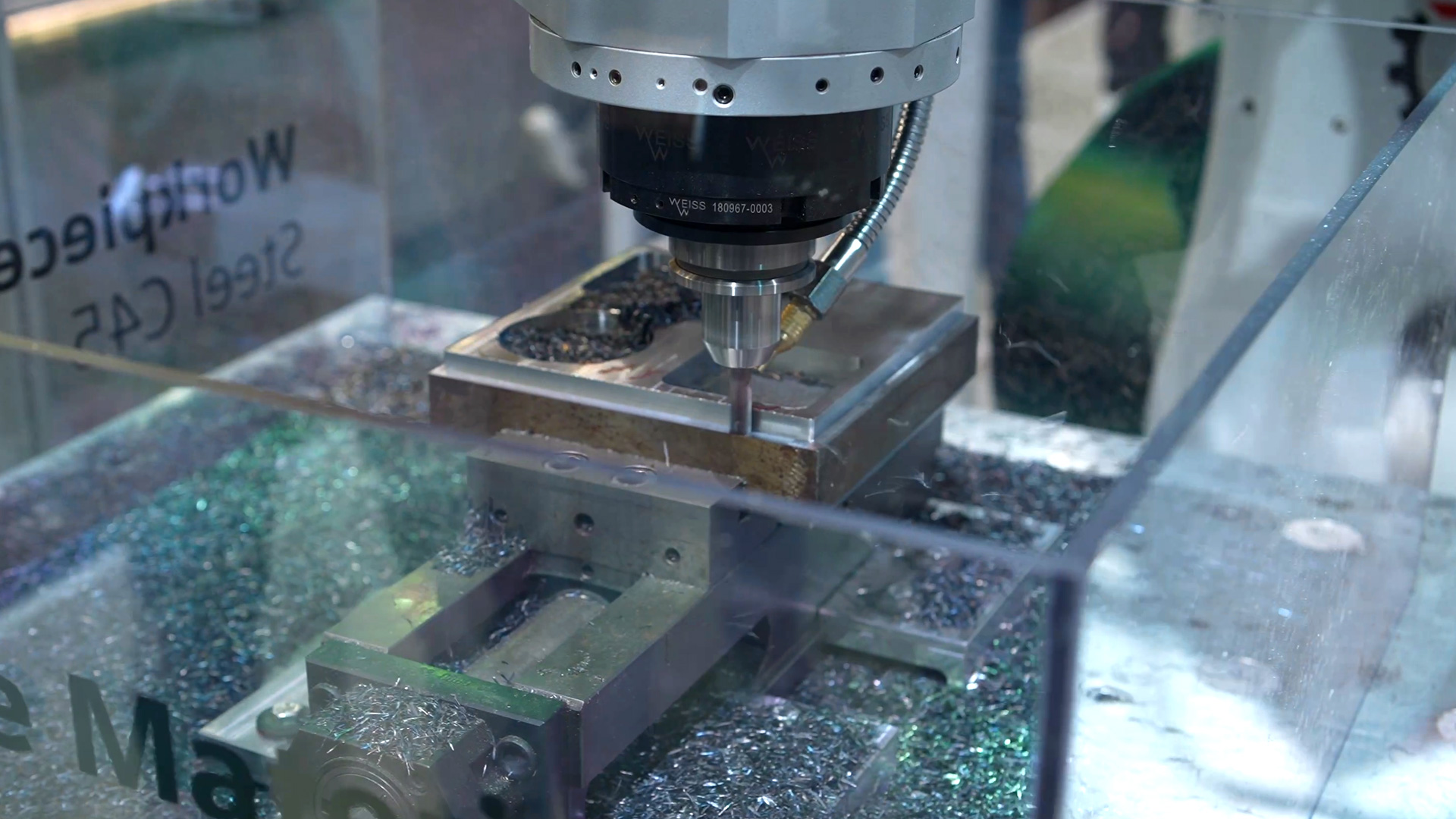

The MTR Machine Tool Robot is being developed in collaboration with partners from the automation industry. Siemens is responsible for control integration, while the mechanics are provided by leading robot manufacturers. This close collaboration has resulted in a system that not only enables automation, but also expands robots to include high-precision machining tools.

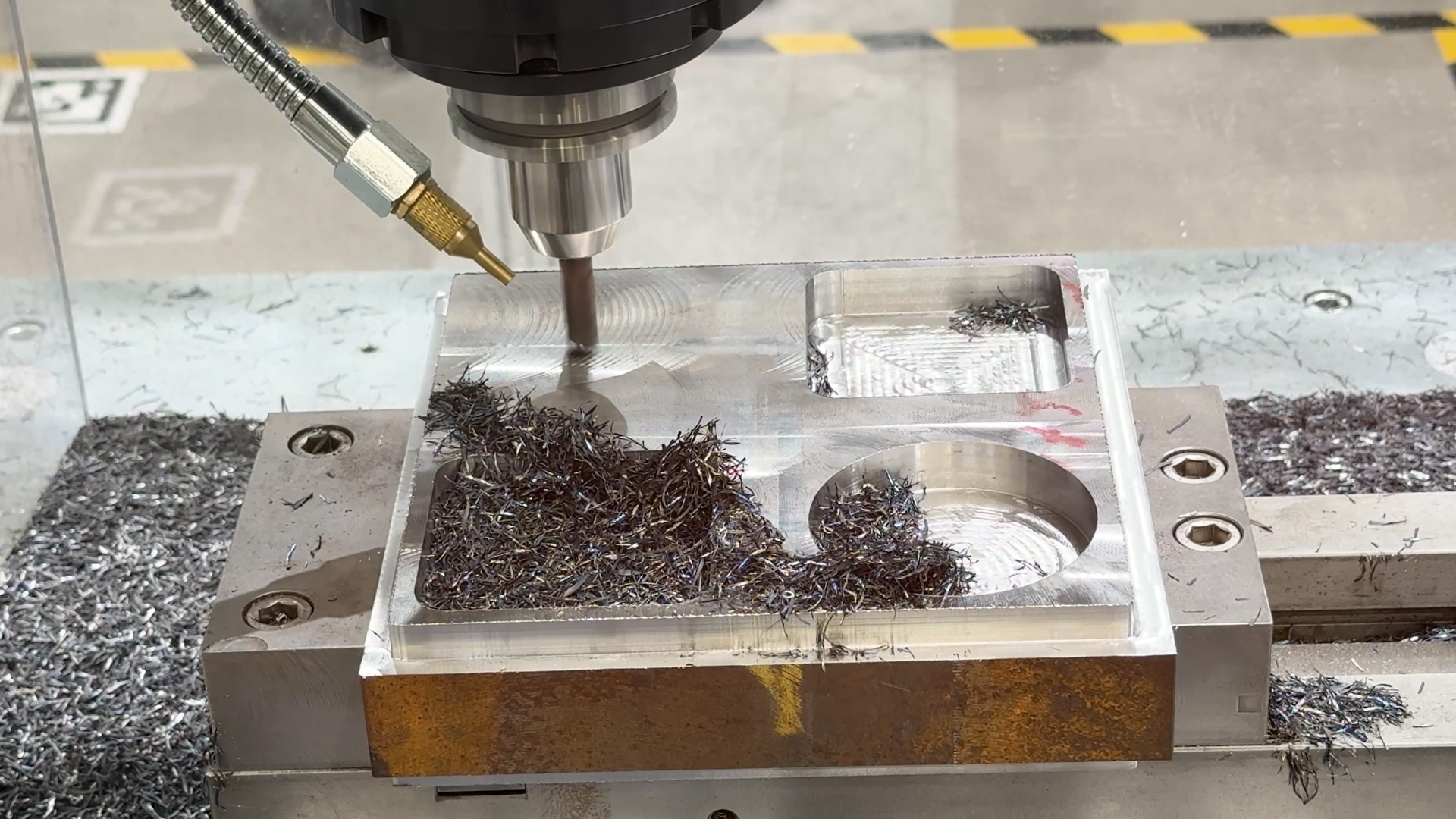

An outstanding feature of the Siemens MTR Machine Tool Robot is its precision: when milling C45 steel, it achieves an accuracy of up to 0.1 millimeters. These values are in the range of classic machine tools and clearly set the robot apart from standard industrial applications. For users, this means new freedom in material processing and complex manufacturing processes.

The solution offers particular advantages in the aerospace and automotive industries. Where large-scale components with complex geometries need to be machined, the Siemens MTR Machine Tool Robot delivers the required precision. The ability to mill car body or structural components in a large machining area using CNC-controlled robot technology pushes the boundaries of conventional manufacturing processes.

The solution does not replace a machine tool in the traditional sense, but it is a valuable addition. The Siemens MTR Machine Tool Robot opens up new options, especially in flexible manufacturing cells or hybrid production systems. Users benefit from a combination of robust robot kinematics, intelligent control software, and high process stability, which can have a significant impact on manufacturing strategies for the future.