At EMO in Hanover, EMAG will be presenting a wide range of manufacturing technologies and innovations in Hall 17. Visitors will gain insights into the latest machines, applications, and turnkey solutions developed for efficient industrial production. The company will demonstrate how digitalization, automation, and service will be interlinked in the future.

The portfolio at the trade fair stand ranges from classic processes such as turning and grinding to gear hobbing. Various machines and applications from the group's entire product range will be on display. These include innovations in the turning and gear cutting sectors that specifically address the increasing demands in component manufacturing. The exhibition is complemented by innovative clamping concepts developed in cooperation with partner Sterman. These enable the safe machining of even critical and thin-walled components.

A central highlight of the trade fair is the VT 200 twin-spindle horizontal turning machine. In combination with a robot cell, it demonstrates how complex workpieces such as a differential housing can be completely manufactured in a single setup. In addition to machining, measuring, marking, and automated handling are also integrated. This turnkey application shows how EMAG designs processes to be fully automated and efficient at the same time.

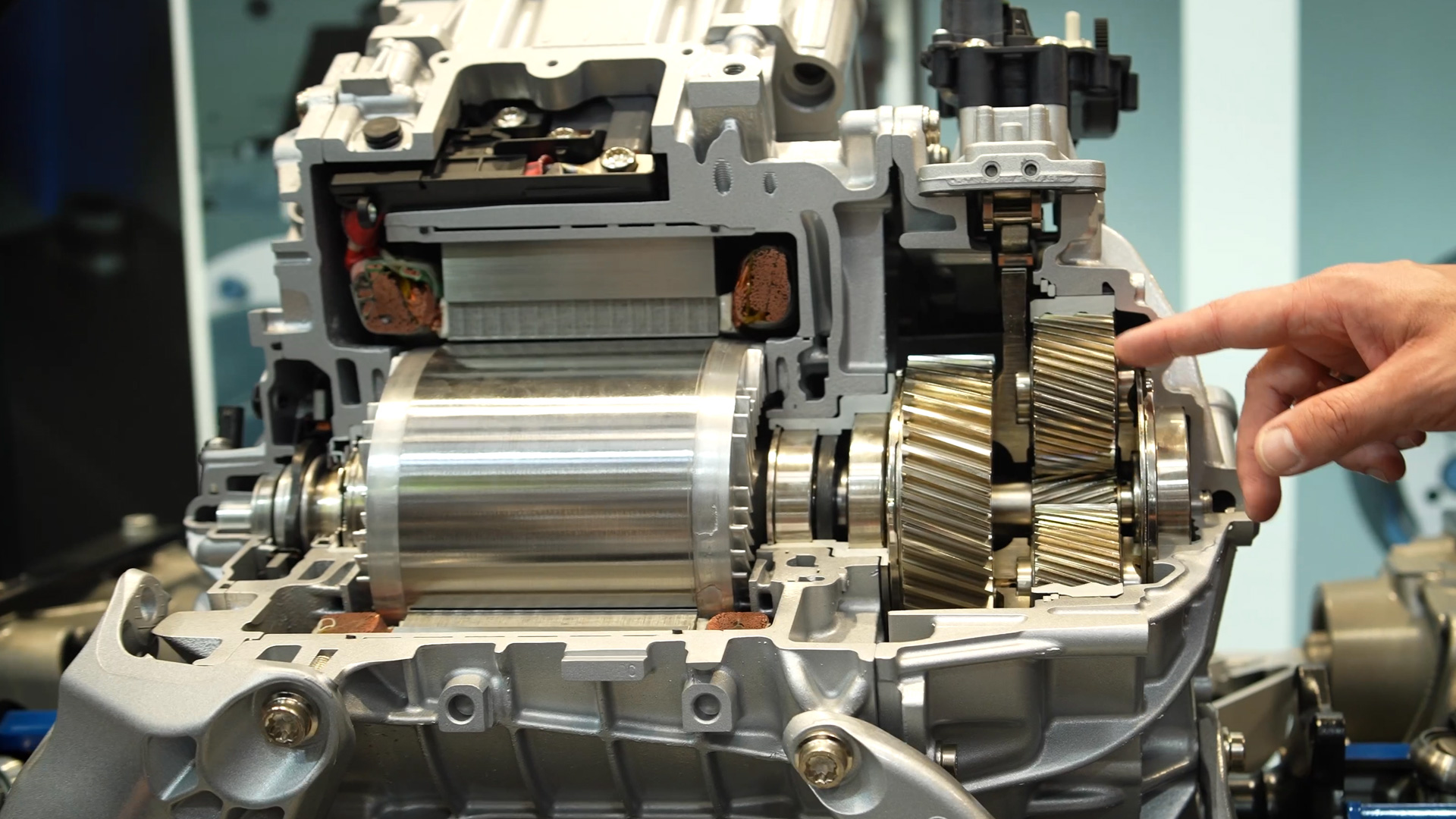

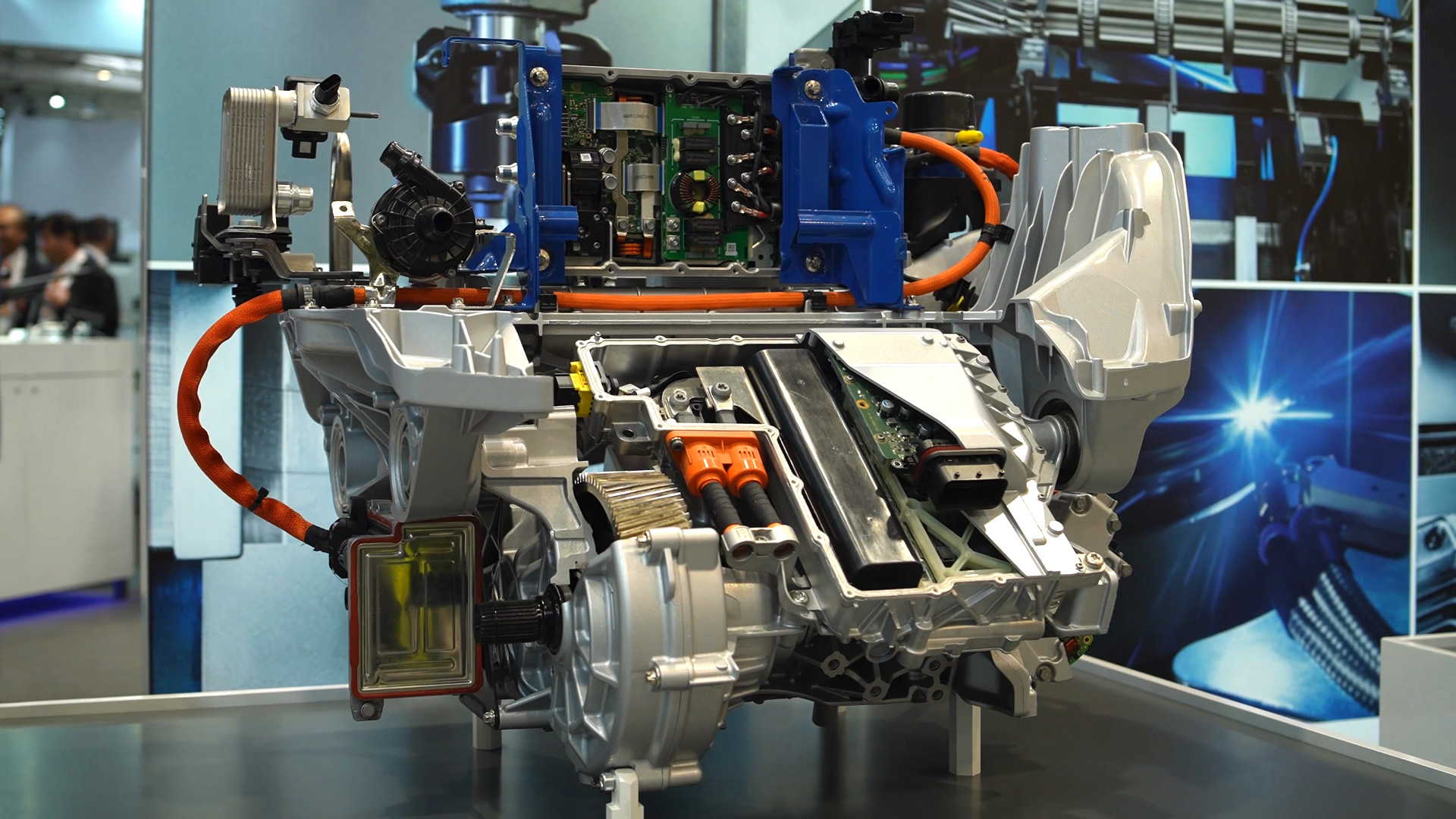

Special attention is being paid to new developments in the field of gear hobbing, which are crucial for modern transmission applications. By combining these developments with innovative clamping solutions, even complex components can be manufactured with precision. EMAG is thus taking the combination of mechanical engineering and clamping technology to a new level and addressing key challenges facing the industry.

In addition to machines and technologies, EMAG is focusing on the future topics of service and digitalization. A 24/7 service offering is designed to ensure that systems remain available at all times. Digital tools are to be integrated more closely: optimized tool monitoring, shorter downtimes, and intelligent automation are key objectives. This approach is intended to help shorten cycle times and make processes more stable.

Looking ahead, it is clear that EMAG wants to move beyond its role as a traditional machine manufacturer. The focus is on responsibility for complete turnkey projects in which mechanics, automation, and digital support work closely together. The company is thus signaling that competitiveness in the future will be determined not only by machine quality, but also by comprehensive system solutions.