BrauKon has established itself as a specialist in brewery plant engineering for more than two decades. The Seeon-based company develops customized solutions for medium-sized breweries - from pubs to the upper mid-range. At drinktec 2025, BrauKon will be presenting a 40-hectoliter brewhouse for the Loscher brewery as well as innovative technologies and the close connection to the company's own brewery Camba Bavaria.

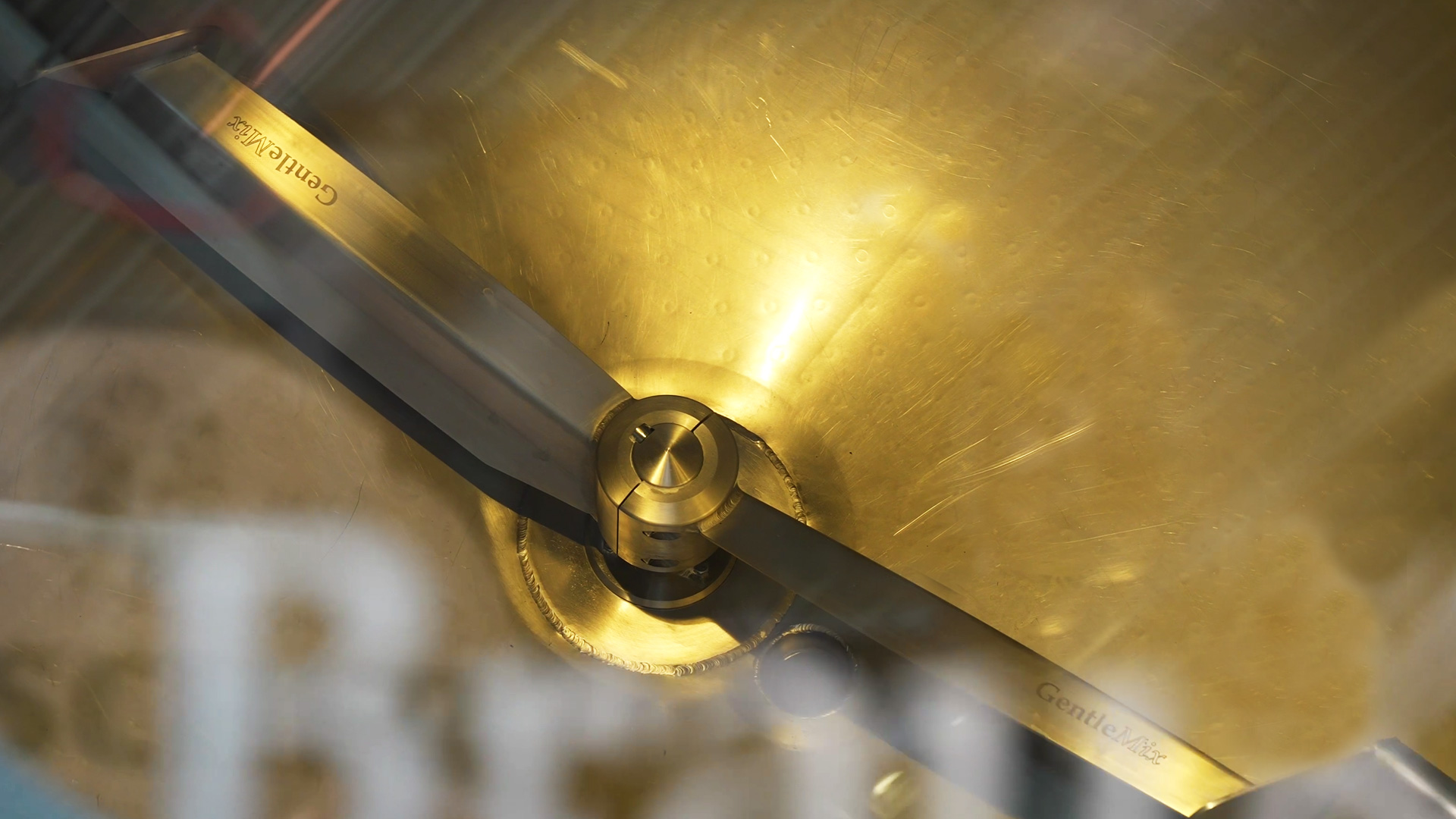

BrauKon's service portfolio ranges from small and pub breweries to larger medium-sized companies. One prominent example is Tegernseer Brauhaus, whose brewhouse was made by BrauKon. At the trade fair in Munich, the company will be demonstrating its expertise with a 40-hectoliter brewhouse built for the Loscher brewery. Two central vessels will be on display - the mash tun with Gentle Mix mill and AlloySius pre-mash as well as the lauter tun with modern technology for separating mash and husks. After the trade fair, the systems go directly to the customer, while the remaining components are completed in Seeon at the same time.

BrauKon operates internationally and supplies brewery systems not only to German-speaking countries, but also to Europe, Asia and Africa. Despite the global orientation, the home market in Germany remains central. Innovations are not only created in the design department, but are closely linked to the company's own brewery Camba Bavaria. This special feature allows new technologies and processes to be tested in practice before they are passed on to customers.

The in-house brewery Camba Bavaria is a unique selling point in brewery plant construction. It serves as a testing ground for new technologies and as a place where ideas are developed to market maturity. With over 120 beers brewed last year - from pale varieties to numerous special and customer creations - Camba Bavaria offers an enormous variety. Visitors to Seeon can tour the brewery, take part in self-guided tours and taste the wide range of products directly. This will also be visible at drinktec: BrauKon will be showcasing beers from its own production and from customers with twelve taps. This provides a hands-on experience of how innovative systems work in the finished product.

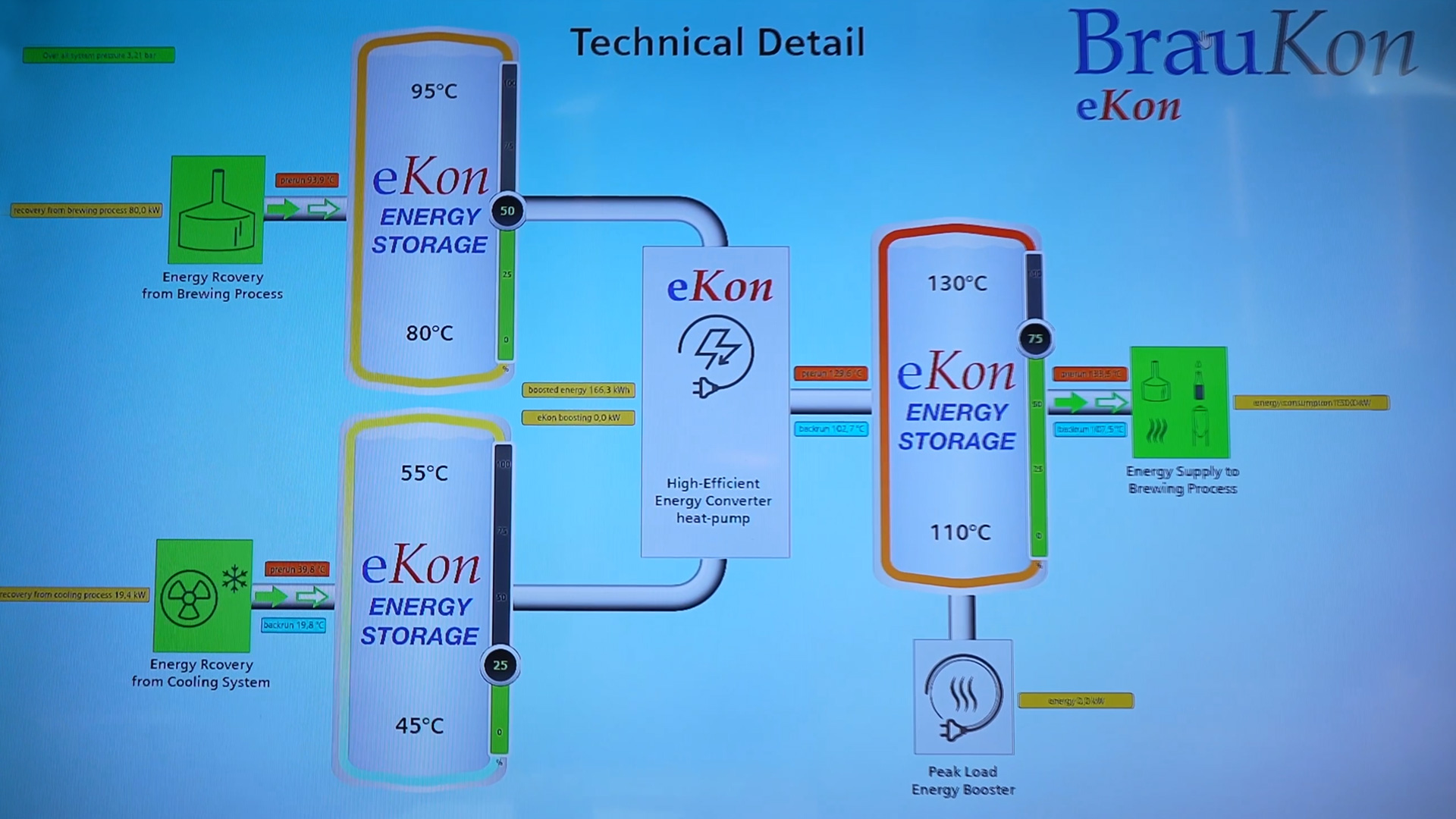

A technical highlight at the BrauKon stand is the patented eKon heat pump. It not only uses the waste heat from the brewing process, but also recovers energy from cold production - an approach that is unique in this form. Both energy sources are bundled in a pressure tank and heated up to 130 degrees. The stored heat flows directly back into the brewing process, making parts of the energy supply in the brewhouse self-sufficient.

For breweries, this means lower energy costs and a significant reduction in the carbon footprint. The technology therefore contributes to two key factors: Economic efficiency and sustainability. For medium-sized companies in particular, the heat pump opens up the possibility of cushioning rising energy costs and meeting ecological requirements at the same time. The eKon technology has a modular design, can also be integrated into existing systems and was developed by BrauKon specifically for the food sector. The patent underlines its innovative character and shows how strongly the company is driving forward practical solutions with sustainable added value.

Since its foundation, BrauKon has set itself the goal of providing medium-sized breweries with flexibility through technical innovations. Large breweries benefit from their efficiency and size, while smaller companies need customized solutions in order to remain competitive.

BrauKon supports them with modular brewhouses, new energy approaches and field-tested technologies from Camba Bavaria. Numerous well-known breweries in Germany are now customers, and the company's influence is also growing steadily internationally. drinktec 2025 underlines the fact that BrauKon combines plant engineering, the art of brewing and energy efficiency into a coherent overall concept - with tradition in Bavaria and projects worldwide.