Lanxess has been a major player in the specialty chemicals industry for many years and is a reliable partner to the international beverage industry. At drinktec 2025 in Munich, the company presented its trade fair presentation with focus on two key areas: Nagardo, a natural preservative that offers an alternative to conventional chemical solutions. Lanxess also presented its proven Velcorin cold sterilization technology, which has been established in the industry for four decades and is now complemented by modern dosing technology and digital networking.

One highlight of the trade fair presentation was Nagardo. The agent is extracted from a fungus and protects beverages from microbiological contamination – i.e., from yeast, mold, and bacteria. Nagardo is the first preservative of its kind that works on a natural basis, making it a true innovation. While previous solutions were mostly chemically produced, Lanxess is responding to consumer demand for shorter ingredient lists and fewer additives with Nagardo. For the industry, this means the possibility of preserving beverages without traditional chemical preservatives. Nagardo opens up new perspectives, especially in the non-alcoholic beer segment. Since alcohol is not present as a natural barrier against microorganisms, these products are more susceptible to contamination. Heat treatment is not an option for draft beer in the catering sector. Here, Nagardo offers a regulatory-approved solution to extend shelf life and reliably prevent contamination – an advantage for both breweries and catering businesses.

In addition to the new development, the focus was also on a classic: Velcorin. The substance has been used in the beverage industry for almost 40 years and is considered an “oldie but goldie.” Like Nagardo, Velcorin is effective against yeast, mold, and bacteria, but it is a so-called processing aid. It is added to the beverage via a dosing system immediately before bottling. Within a few hours, the substance decomposes completely into methanol and CO₂, so that it is no longer present in the final product. Consumers enjoy their beverage without residues, while the manufacturing process remains safe.

To illustrate the possible applications, Lanxess brought three sample products to the trade fair. A grapefruit lemonade was stabilized exclusively with Velcorin, as the carbon dioxide present provides additional protection. A lime lemonade, on the other hand, was treated only with Nagardo and also did not require any further additives. For iced tea—a still beverage and therefore more susceptible to germs—Lanxess combined both agents. This demonstrated that the combination of Nagardo and Velcorin also ensures reliable protection against contamination in particularly sensitive products.

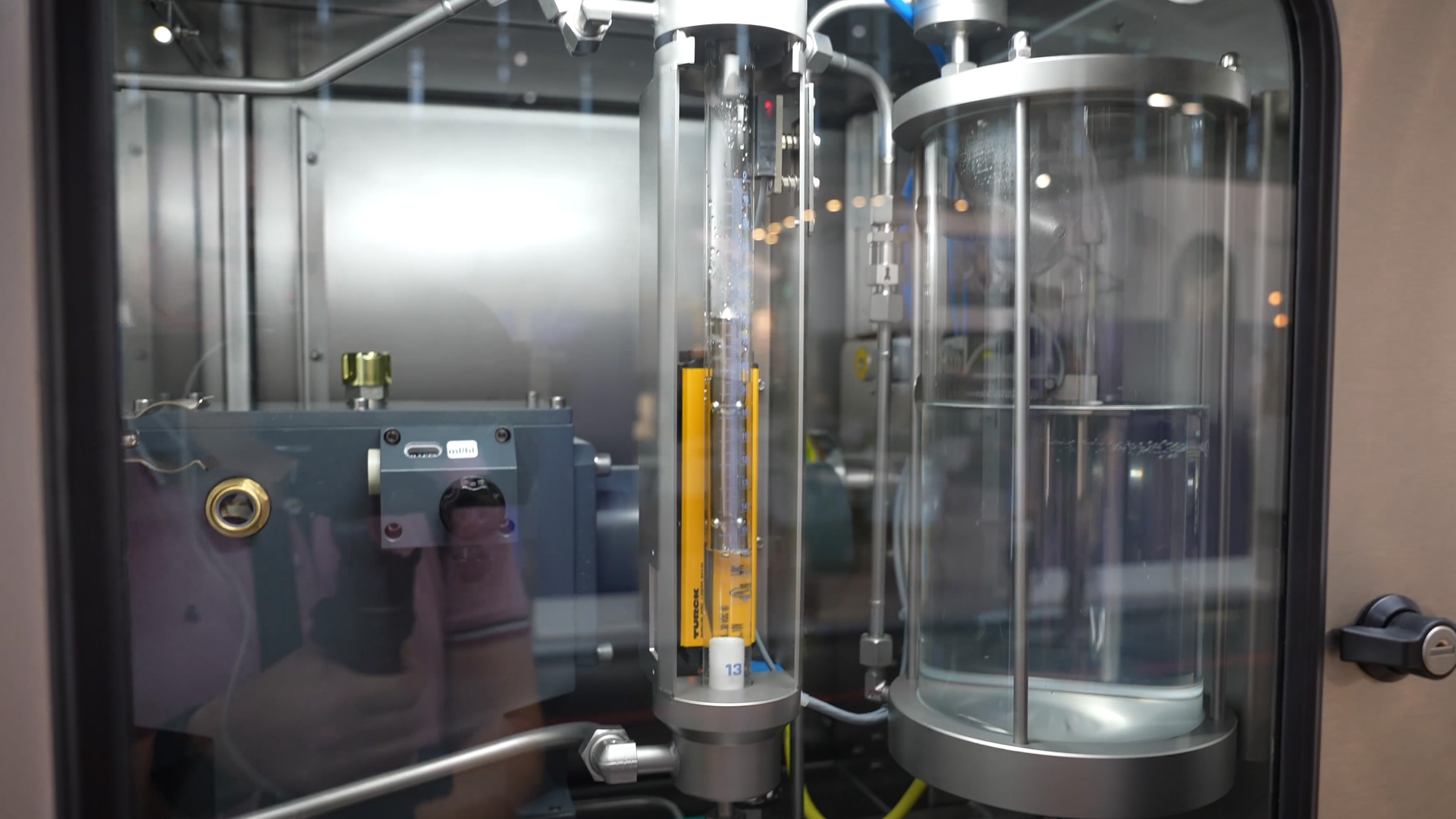

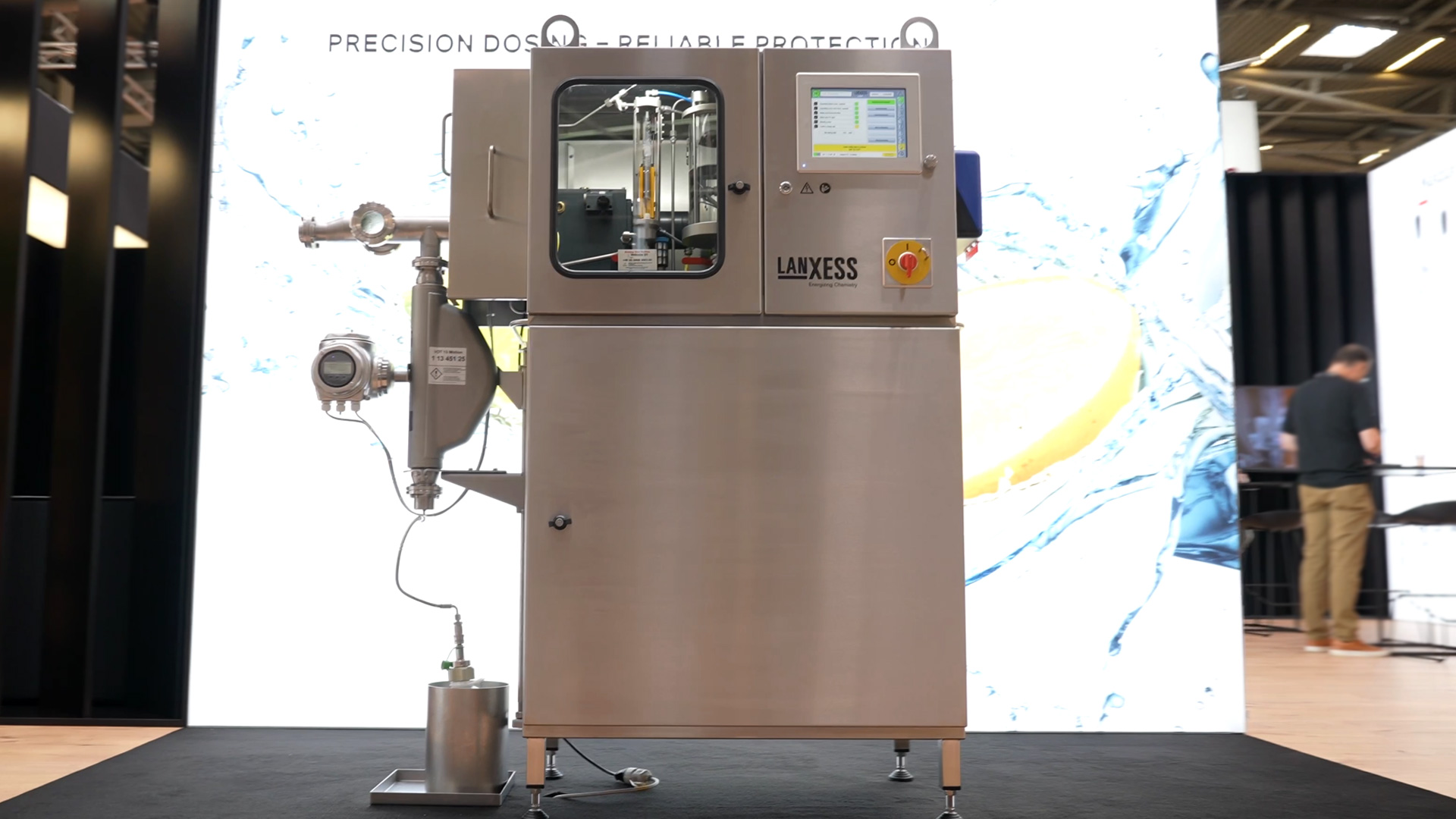

In addition to the products themselves, Lanxess also presented the latest generation of its dosing technology. The devices add Velcorin to the beverage shortly before bottling and have been established in the industry for decades. The main new feature is the digital interfaces: production data can be recorded and evaluated in real time and networked with the customer's machinery. A graphical visualization ensures that manufacturers have an overview of the dosing and process at all times.

Another detail is the new flow meter from Endress+Hauser, which has been integrated into the system. It opens up additional possibilities for diagnosis and data evaluation and ensures more precise process control. This underlines Lanxess' commitment to continuously modernizing its technology and adapting it to the requirements of the industry.

There are four years between each drinktec trade fair – time that Lanxess uses to work closely with customers to identify new requirements and wishes. These are regularly incorporated into the next generation of products and systems. The result will be evident again in 2025: With Nagardo as a natural alternative, Velcorin as a proven cold sterilizing agent, and modern dosing technology, Lanxess presents itself as an innovation partner for safe and high-quality beverages.