Automation has become indispensable for companies worldwide in order to counter the shortage of skilled workers, reduce costs and make production processes more efficient. HOLZ Automation develops individual special machines that are precisely tailored to the specific requirements of customers. Instead of relying on standard solutions, the company creates tailor-made automation technology that optimizes production processes and makes them competitive in the long term.

Every production environment has individual requirements that often cannot be optimally covered by standard machines. This is why every project at HOLZ Automation starts on a blank sheet of paper: together with the customer, technical requirements, space conditions and production targets are analyzed in order to develop a tailor-made automation solution. From small, compact manual workstations to large, two-storey systems over 25 meters long, HOLZ Automation offers highly flexible solutions for a wide range of industries. Whether miniature systems or complex production lines, the machines are precisely tailored to the respective production requirements and spatial conditions. One example is a specially developed testing machine for asthma sprays, which automatically shakes them and checks their functionality. Such high-precision special solutions illustrate how HOLZ Automation guarantees maximum efficiency and quality with individually designed machines.

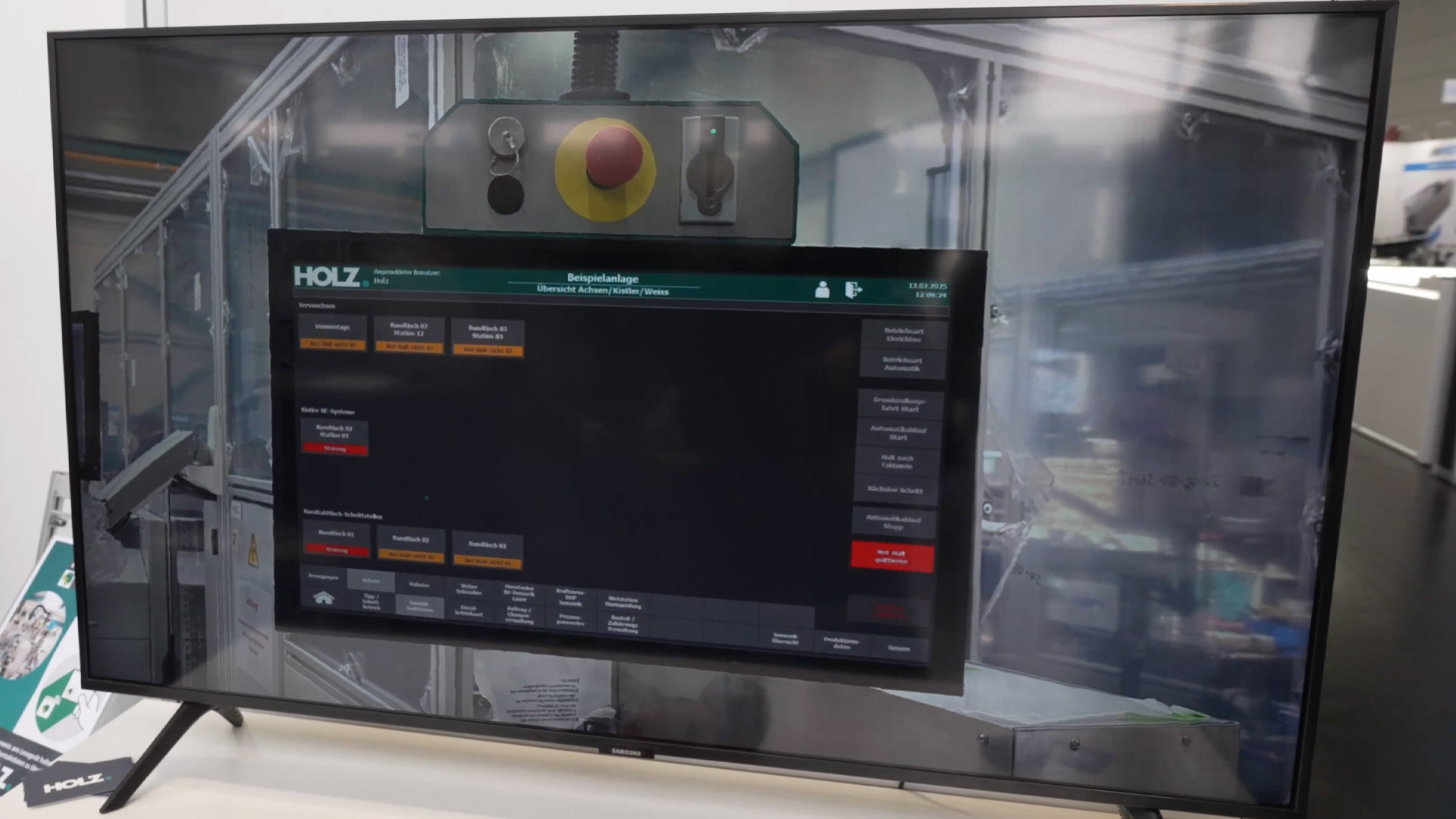

Intuitive operability is a decisive factor in modern automation. HOLZ Automation relies on its own software solution in collaboration with Siemens. The user-friendly HMI control system enables the operator to control and evaluate all relevant process parameters directly via an integrated display or even a mobile device. In addition, a host computer system with process data management is used to record and evaluate all production data. This allows the machines to be seamlessly connected to MES or SAP systems so that all real-time data can be accessed centrally. This technology offers companies a clear competitive advantage, as they can monitor the current production status at all times and react to deviations at an early stage. Production data such as output figures, process stability and quality parameters can be called up at any time and enable precise planning and optimization of the entire production process.

Unplanned machine downtime means lost production and high costs. HOLZ Automation is therefore increasingly focusing on preventive maintenance concepts (predictive maintenance). By permanently recording machine data, signs of wear and tear are detected at an early stage so that maintenance measures can be carried out in a targeted manner before a breakdown occurs. Another key element is automated quality assurance. Machines from HOLZ Automation can record and evaluate test data so that the customer is provided with a certificate of fault-free products at the end of a production cycle. This seamless documentation not only helps to reduce rejects and complaints, but also strengthens the end customer's confidence in the quality of the goods produced.

HOLZ Automation pursues a customer-oriented service philosophy: instead of concluding rigid maintenance contracts, the company relies on a needs-based service offering. Once the system has been installed, customers receive an individual recommendation for spare parts and inspection intervals, but can decide for themselves which measures are necessary. The annual inspection is not sold as a flat-rate service contract, but is individually adapted to the condition and actual use of the machine. This transparent and needs-based maintenance policy enables companies to save costs without having to compromise on reliable system availability.

HOLZ Automation does not offer standard solutions, but develops customized machines that are precisely adapted to the requirements of the respective production. The combination of flexible design, intelligent software integration and predictive maintenance ensures efficient automation that keeps companies competitive in the long term. Thanks to seamless connection to existing IT systems, predictive maintenance and intuitive operation, HOLZ Automation ensures that companies can efficiently control their production, reduce costs and sustainably improve quality.

HOLZ automation is an internationally active company based in Backnang, Germany, which specializes in plant engineering, special machine construction and automation technology. With many years of experience, the company develops customized solutions for various sectors, including automotive, industry, consumer goods and healthcare. The range of services extends from planning and design to the commissioning of complex automation systems. An interdisciplinary team of engineers and technicians works on the implementation of efficient and individual solutions.