KHS GmbH: Filling and packaging technology for the beverage industry

KHS GmbH is one of the world's leading suppliers of filling and packaging solutions for the beverage and food industry. Based in Dortmund, the company combines decades of engineering tradition with modern plant and process technology. KHS stands for integrated systems that combine efficiency, product safety, and sustainability and are used by beverage manufacturers on an industrial scale worldwide.

Historical development and market position

KHS was founded in 1868 and developed from a traditional machine manufacturer for breweries into a global system provider. Over many decades, the company has continuously expanded its expertise – from pure filling technology to complete line solutions including packaging, inspection, and process integration. Today, KHS has an international presence and serves customers in almost all relevant beverage segments, including beer, water, soft drinks, juices, milk-based beverages, and wine. A key factor in its success is its close cooperation with beverage manufacturers, which enables KHS to design systems precisely to specific production requirements. The focus is on process stability, hygienic design, and high system availability.

Technologies and system concepts

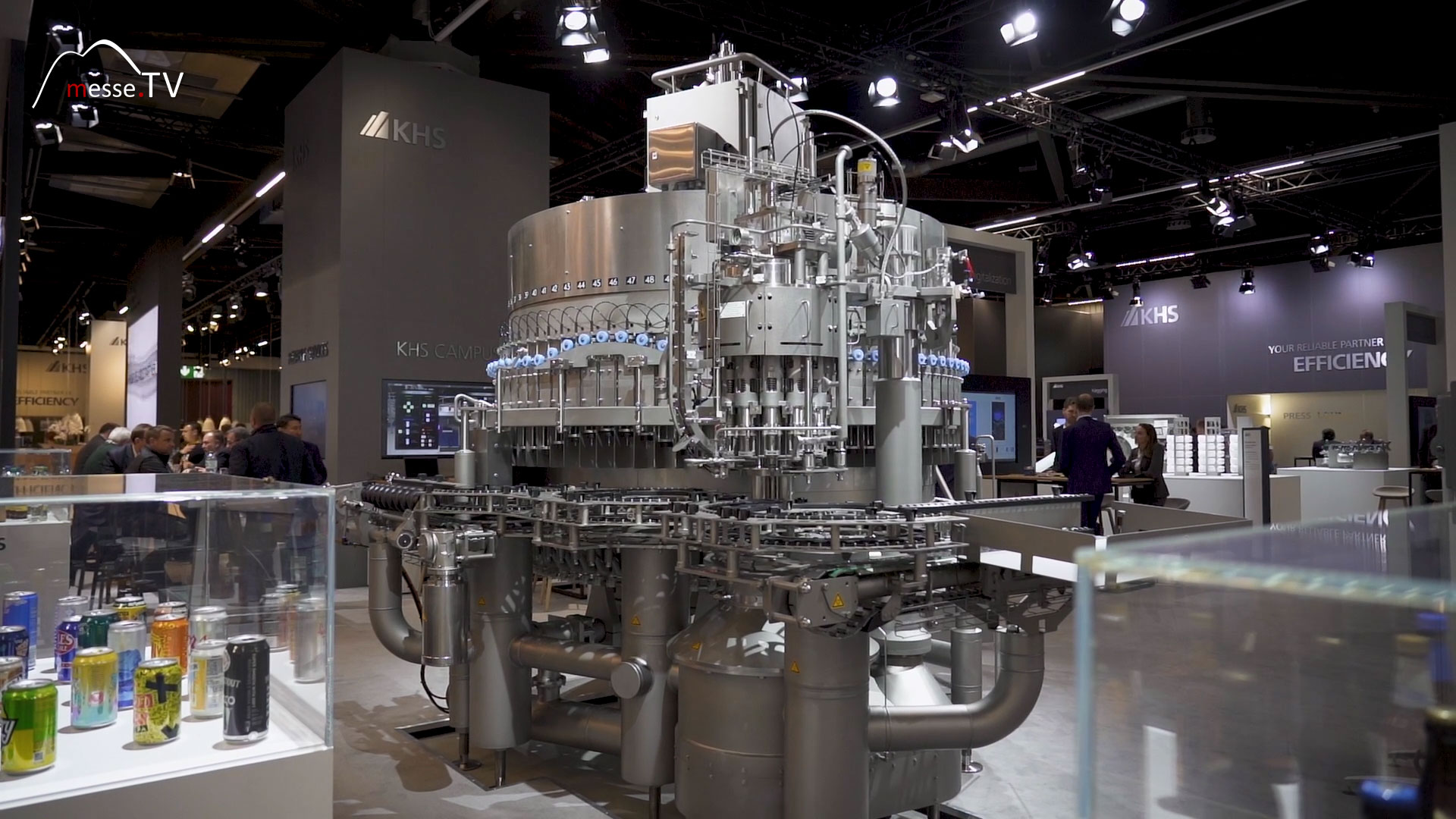

The KHS product and solution portfolio covers the entire filling and packaging process. This includes filling systems for glass and PET bottles, cans, and alternative container shapes, as well as labeling machines, packaging systems, and transport technology. A particular focus is placed on hygienic filling concepts that meet the increasing requirements for product safety and quality assurance. Typical areas of expertise at KHS include:

- High-precision filling systems for various types of beverages

- Table-less and hygienic filling concepts

- Flexible packaging solutions for different containers

- integrated line control and process optimization

Articles about KHS on Messe.TV

Modern beer fillers: hygienic design and energy efficiency

Beverage filling is one of the most sensitive stages of industrial production processes. Hardly any other area combines so many requirements at the sa... Beverage fillingSustainability and resource efficiency

Sustainability is a central component of KHS's corporate strategy. The development of energy- and resource-saving systems aims to measurably reduce water, energy, and material consumption in beverage production. An important focus is on packaging solutions with reduced material usage as well as recyclable and reusable concepts, especially in the PET sector. In addition, KHS supports its customers with systems for recycling packaging materials and with technologies that reduce CO₂ emissions along the production chain. Efficiency gains are achieved not only through new machines, but also through optimized processes and digital evaluation of operating data.

Significance for the beverage industry

KHS is regarded as a reliable technology partner for large and medium-sized beverage manufacturers worldwide. The combination of technical depth, a global service network, and a long-term plant strategy makes the company an integral part of modern beverage production. Through continuous research and development, KHS contributes significantly to making industrial filling and packaging processes more economical, sustainable, and future-proof. KHS thus plays a key role in the international beverage industry and has been shaping the technical development of filling and packaging solutions for generations.