Herrenknecht AG is one of the world's leading technology providers in mechanical tunnel construction. The company develops tunnel boring machines and special technology for complex infrastructure projects where precision, reliability, and geological adaptability are crucial. Areas of application range from traffic and railway tunnels to supply lines and demanding mining projects. A characteristic feature of Herrenknecht is the high degree of customization of its machines: hardly any two projects are alike, so the technology and design are precisely tailored to the respective ground and project conditions.

The company was founded in Schwanau in 1977 by Martin Herrenknecht. Within a few decades, the early developments for smaller tunnel boring projects gave rise to a globally active technology group. Today, Herrenknecht AG is represented in numerous countries with branches, service centers, and project offices, and is involved in tunnel construction projects on all continents. The international breakthrough came with large-scale projects in transport and railway construction, in which tunnel boring machines were used for the first time in dimensions that had previously been unfeasible. References such as long Alpine crossings, urban metro systems, and underground supply tunnels have contributed significantly to the company's technological leadership. At the same time, Herrenknecht is closely involved in the planning and construction processes and often works with builders and engineering firms in the early stages of projects.

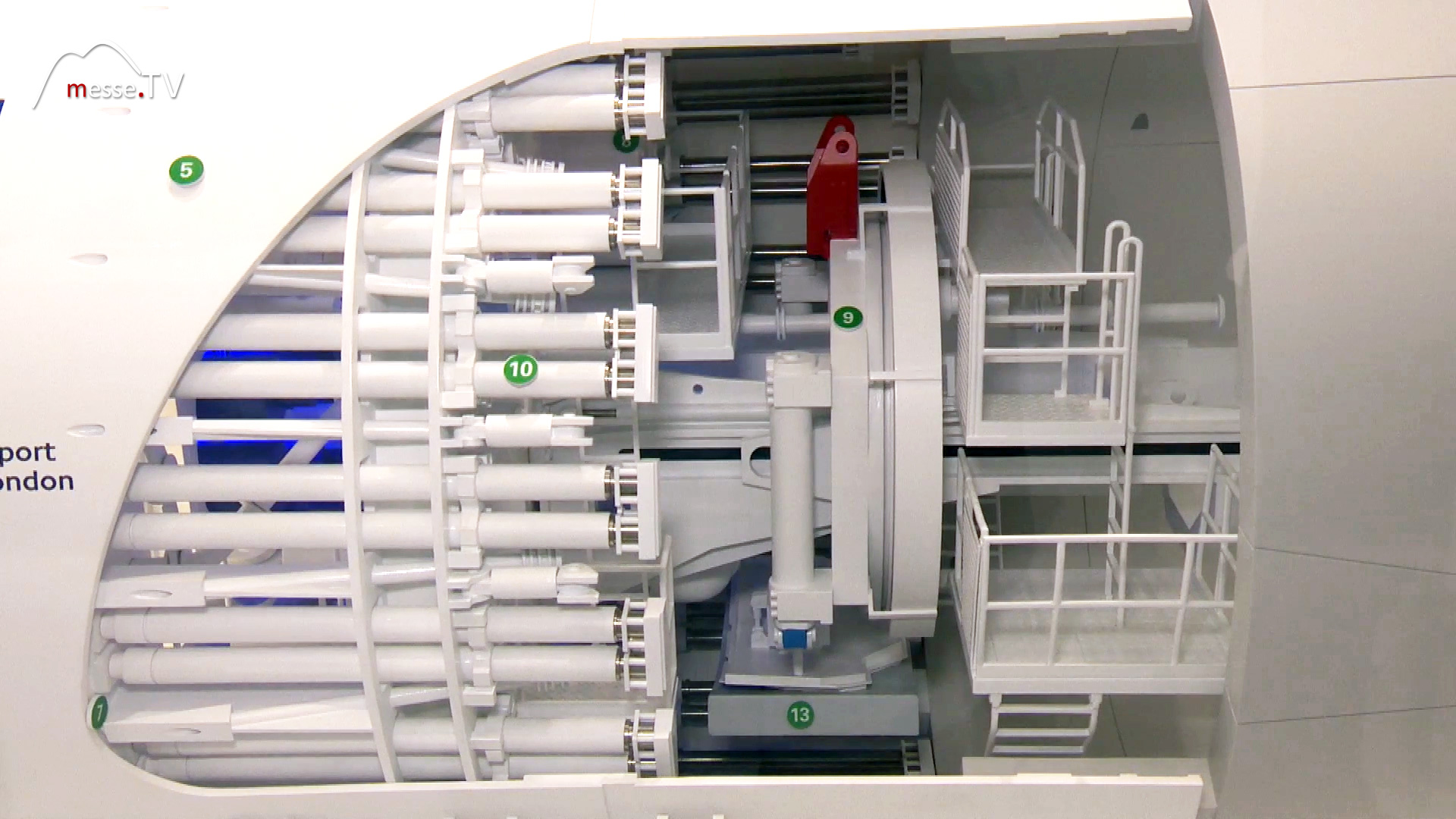

Herrenknecht's product portfolio covers almost all forms of mechanical tunnel and shaft construction. The focus is on tunnel boring machines, which are designed differently depending on the ground conditions, diameter, and area of application. In addition to the actual machine, the complete package also includes logistics systems, conveyor systems, segment assembly, and digital monitoring solutions. Typical machines and areas of application are:

Herrenknecht Tunnel construction

Messe.TV presenter Jürgen Groh in conversation with Achim Kühn from Herrenknecht at InnoTrans 2016 in Berlin. As a result of the trend that rail and m... Herrenknecht Tunnel constructionHERRENKNECHT Mining

When it comes to tunnelling technology and tunnel boring machines, there is no getting around Herrenknecht. We visit the global market leader at bauma... Tunnel boring technology and tunnel boring machinesHerrenknecht does not see itself exclusively as a machine supplier. Its range of services also includes consulting, engineering, commissioning, and service and training concepts throughout the entire project. The availability of technology plays a central role, especially in large-scale projects. Maintenance concepts, spare parts supply, and digital monitoring systems that analyze and optimize tunneling in real time are therefore equally important. Another focus is on the further development of automated processes. Sensors, data analysis, and digital twins are used to make tunnel driving more efficient, safer, and easier to plan. This reduces downtime and allows construction processes to be controlled more precisely.

Sustainability aspects are also becoming increasingly important in underground construction. Herrenknecht is investing specifically in technologies that reduce energy consumption, optimize material use, and reduce emissions. These include more efficient drive concepts, optimized cutting tools, and methods for recycling excavated material. In addition, precisely controlled tunnel boring machines enable a more gentle construction method, especially in urban areas. Lower vibrations and controlled ground movements help to protect existing infrastructure and buildings.

Large-scale projects in the transport and utilities sectors are hardly feasible without mechanical tunnel construction. Herrenknecht has established itself as a technological trendsetter in this field. The combination of engineering expertise, project-specific development, and international experience makes the company an integral part of complex infrastructure projects. This means that Herrenknecht is not only a manufacturer of tunnel boring machines, but also a key partner for the planning and implementation of underground structures – wherever infrastructure is being built under challenging conditions.