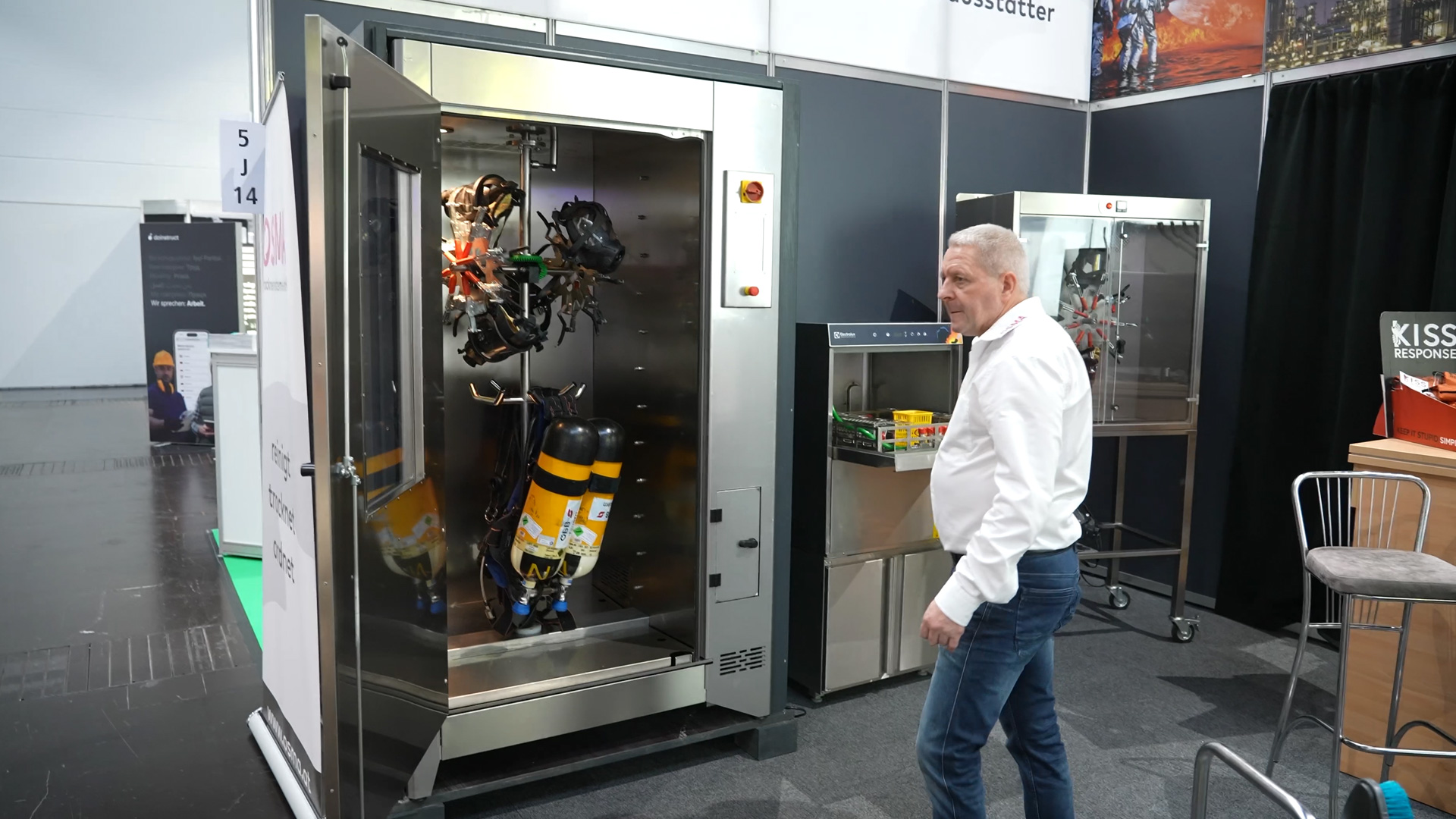

At A+A 2025, OSMA will present a new product for professional respiratory protection care: the Talent. The compact device takes care of all steps – washing, disinfecting, and drying – in a single automated process. Developed for fire departments and companies with respiratory protection technology, the Talent greatly simplifies reprocessing and saves valuable time. Its name says it all: the system is versatile and, in addition to masks, also processes other equipment reliably and gently.

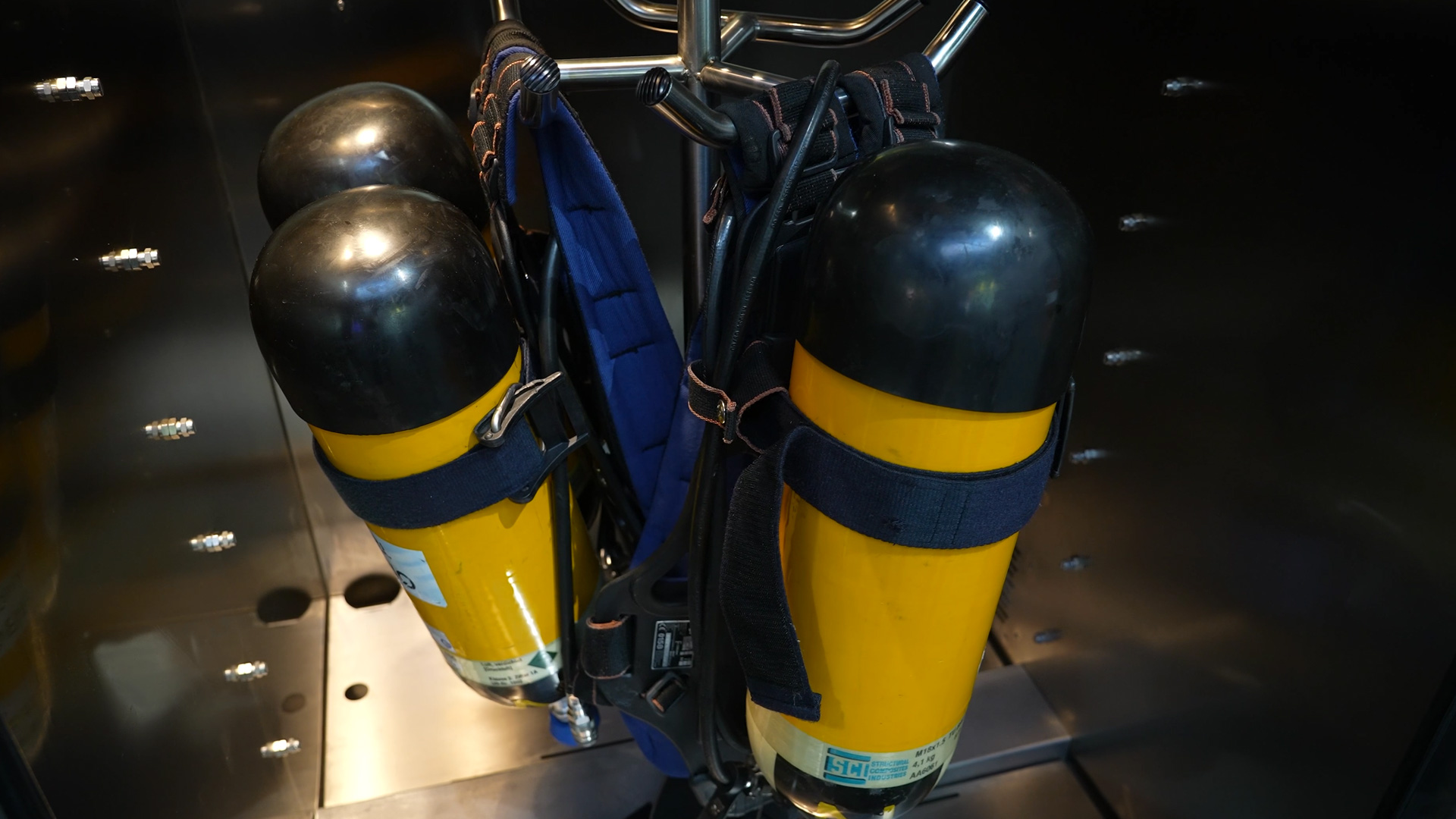

Whereas previously several devices and work steps were necessary, the Talent combines everything in a single cycle. The respiratory masks are attached to a turntable, inserted into the device, and the process is started. The sequence follows a precise order: first, a pre-rinse, then cleaning with detergents, followed by a final rinse and disinfection. The drying process then starts automatically. In about three hours, up to 38 masks can be completely cleaned, disinfected, and dried—a closed process that ensures consistent quality and eliminates the need for manual post-processing.

The most notable technical feature of the OSMA Talent is its drying technology. Conventional cleaning devices usually only manage the washing and disinfection process – but not complete drying. The Talent uses a rotating mechanism that distributes the air evenly, reaching even hard-to-reach areas inside the masks. This ensures that folds, valves, and seals are dried evenly without risking damage to the material. Residual moisture, which could otherwise cause germ formation or odor problems, is reliably removed. The result is dry masks that are ready for immediate use and of consistent quality.

Fire departments in particular benefit from this development. Until now, respiratory protection technicians had to move the masks several times, transferring them from the washing machine to the dryer and finally checking them manually. The Talent reduces this process to a single step. Masks are stretched, inserted, program started – and the result is fully reprocessed masks, ready for inspection and packaging. This means a significant reduction in workload, especially for volunteer fire departments, where cleaning is often done on a voluntary basis. Plant fire departments and service providers can also use the device to reprocess large quantities of equipment in a standardized, safe, and efficient manner.

During the development process, it became apparent that the Talent can do much more than originally planned. In addition to respiratory masks, carrying straps and other textile equipment can also be cleaned, disinfected, and dried – all in one wash cycle. OSMA is thus opening up new possibilities for the standardized care of a wide variety of operational materials. To the best of our knowledge, there is no other device on the market that combines all three processes – cleaning, disinfection, and drying – in one system. The OSMA Talent thus sets a new standard in respiratory protection reprocessing.

With the Talent, OSMA is launching a practical solution that significantly simplifies routine work and ensures hygienic safety. The combined washing, disinfection, and drying process eliminates the need to transfer items between devices, saving time, energy, and personnel resources.