The manufacturer of film packaging machines BVM Brunner is showcasing innovative shipping solutions at LogiMAT 2016 - with a special focus on the e-commerce sector. Dietmar Brunner explains the special features to Messe.TV presenter Klas Bömecke. The range of services extends from packing tables to complete shipping lines and high-end solutions. We also found out what a barcode replicator is and what it is used for. See for yourself!

E-commerce has been booming for years and with it, of course, the mail order business. Now, every product that is shipped must also be suitably packaged. And it is precisely in this area that BVM Brunner is breaking new innovative and efficient ground. Klas Bömecke: Mr. Brunner, great stand. There's a lot of technology to see here, but what do you do in particular? Dietmar Brunner: Well, we are a manufacturer of film packaging machines and we supply everything from packing tables to complete shipping lines, right up to high-end solutions. Klas Bömecke: Okay, and here at LogiMAT - which target group are you addressing? Dietmar Brunner: Well, it's mainly eCommerce, but also automotive, media - everything that's needed for online shipping at the moment.

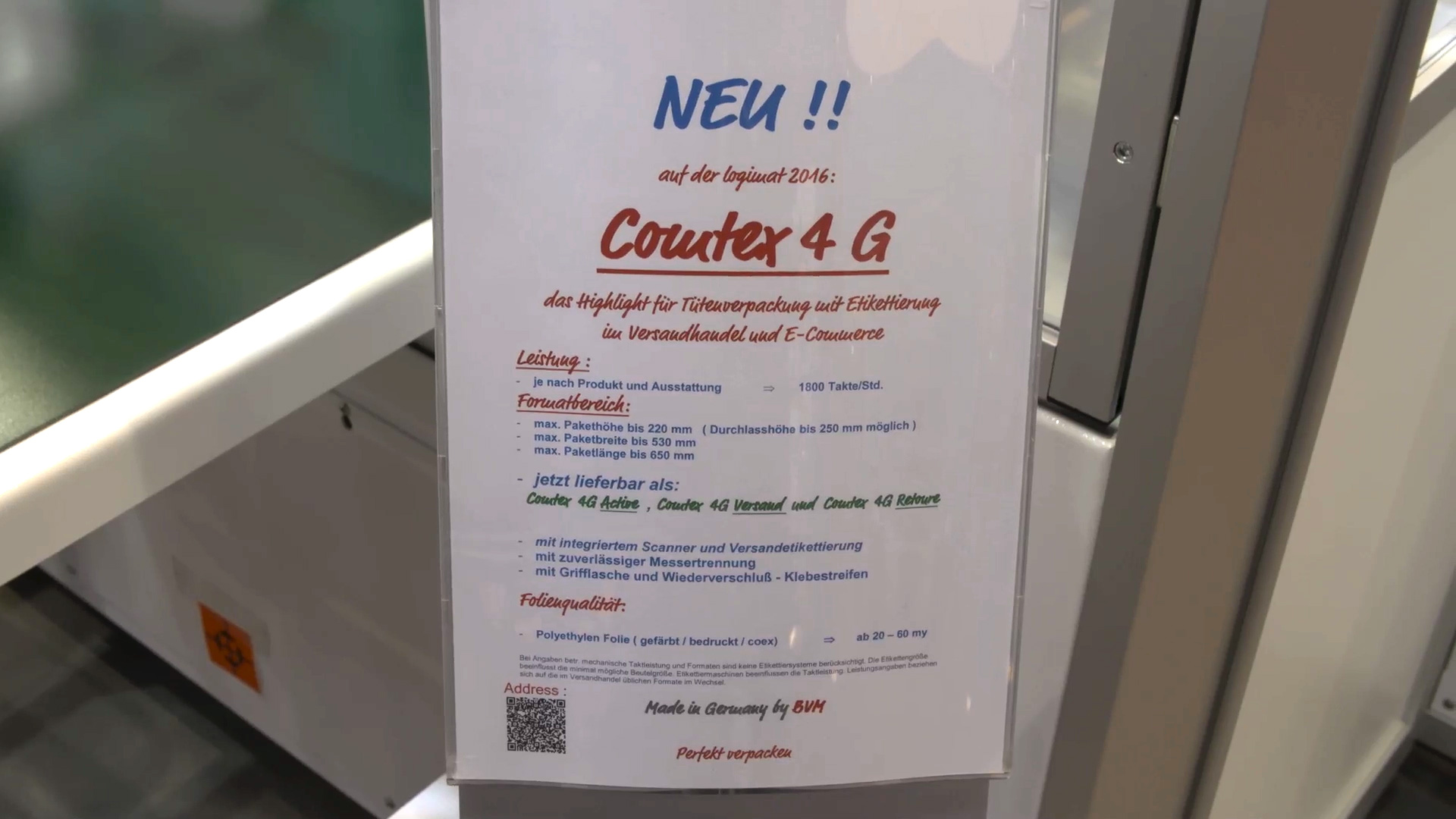

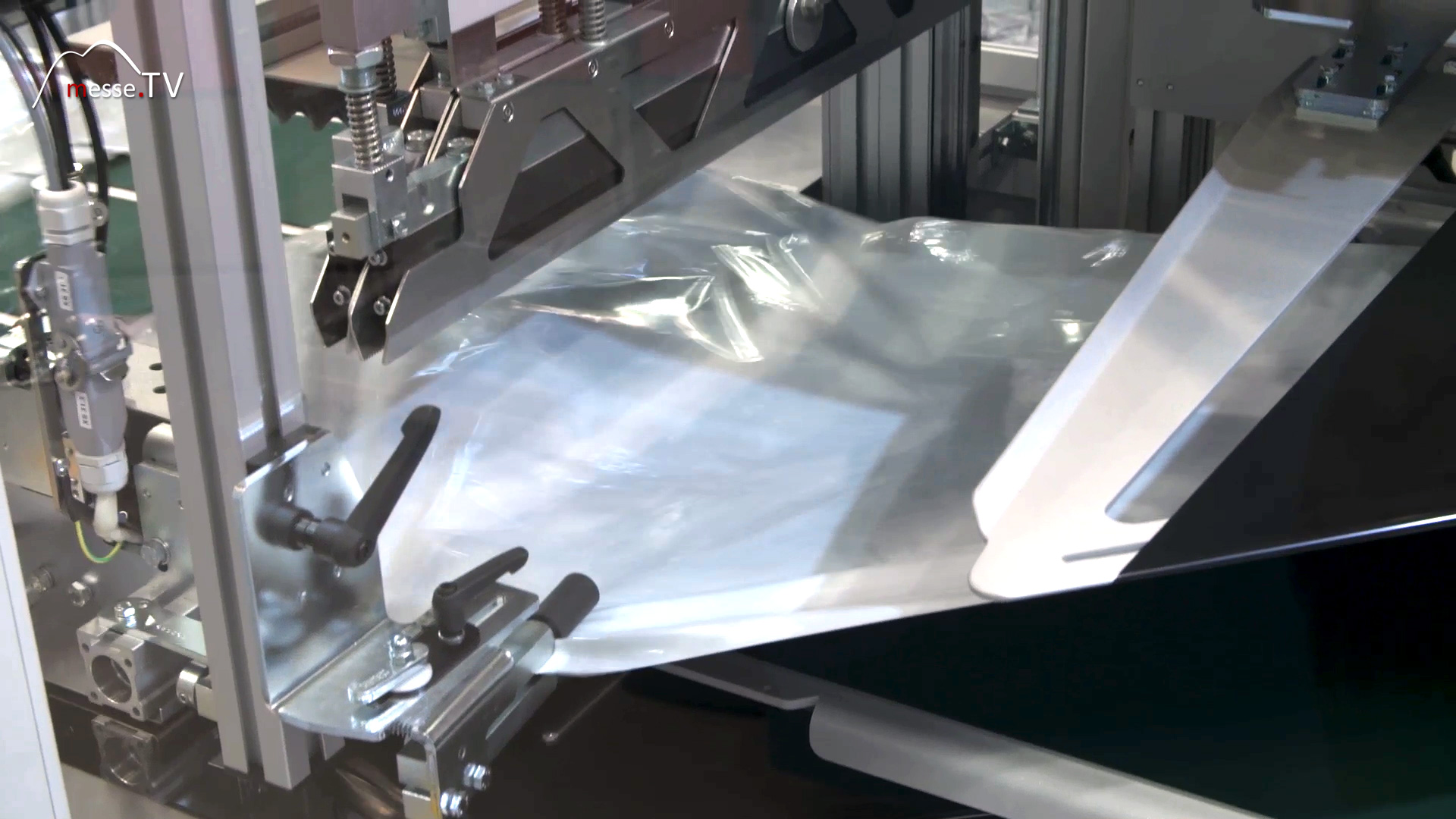

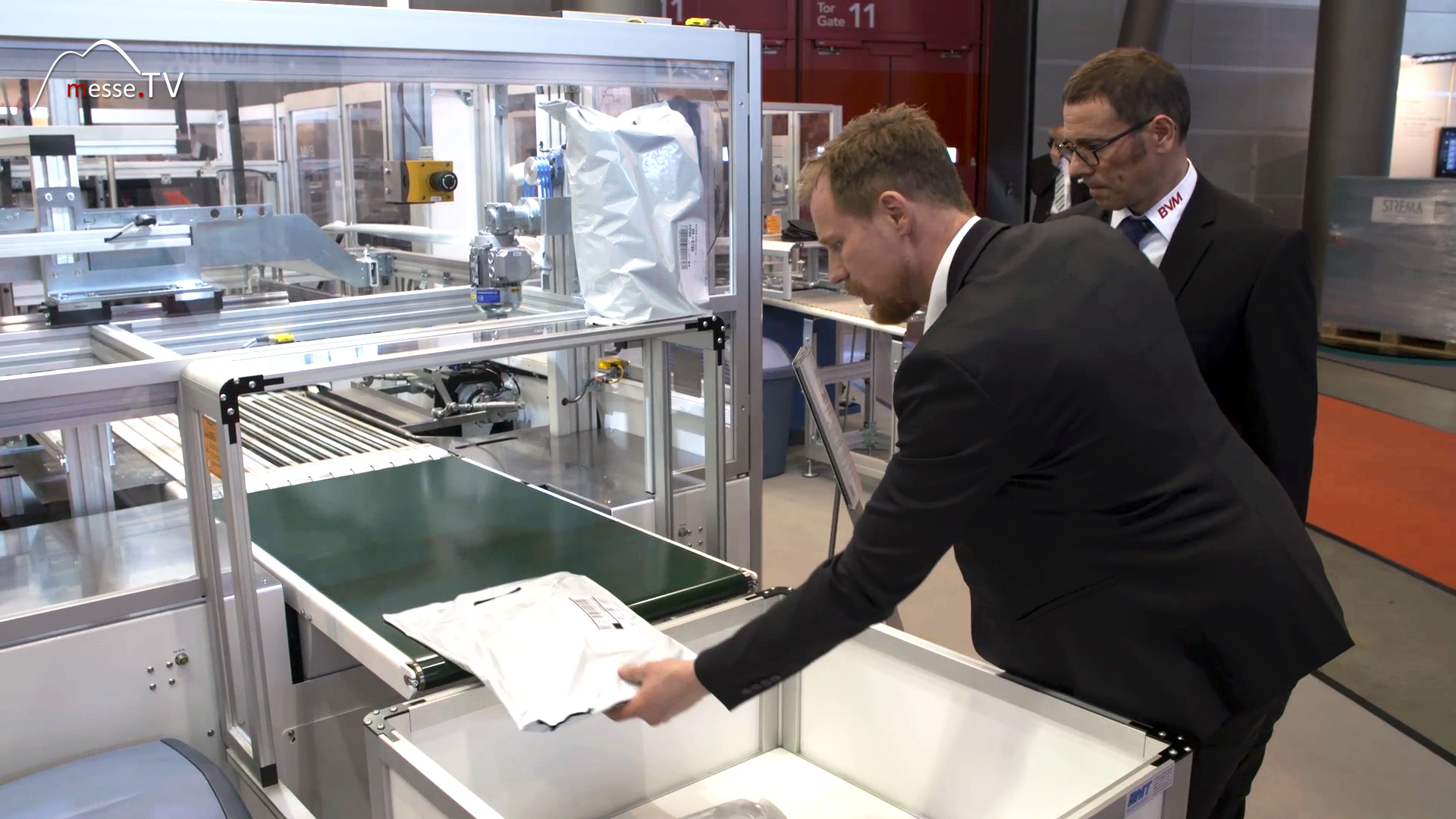

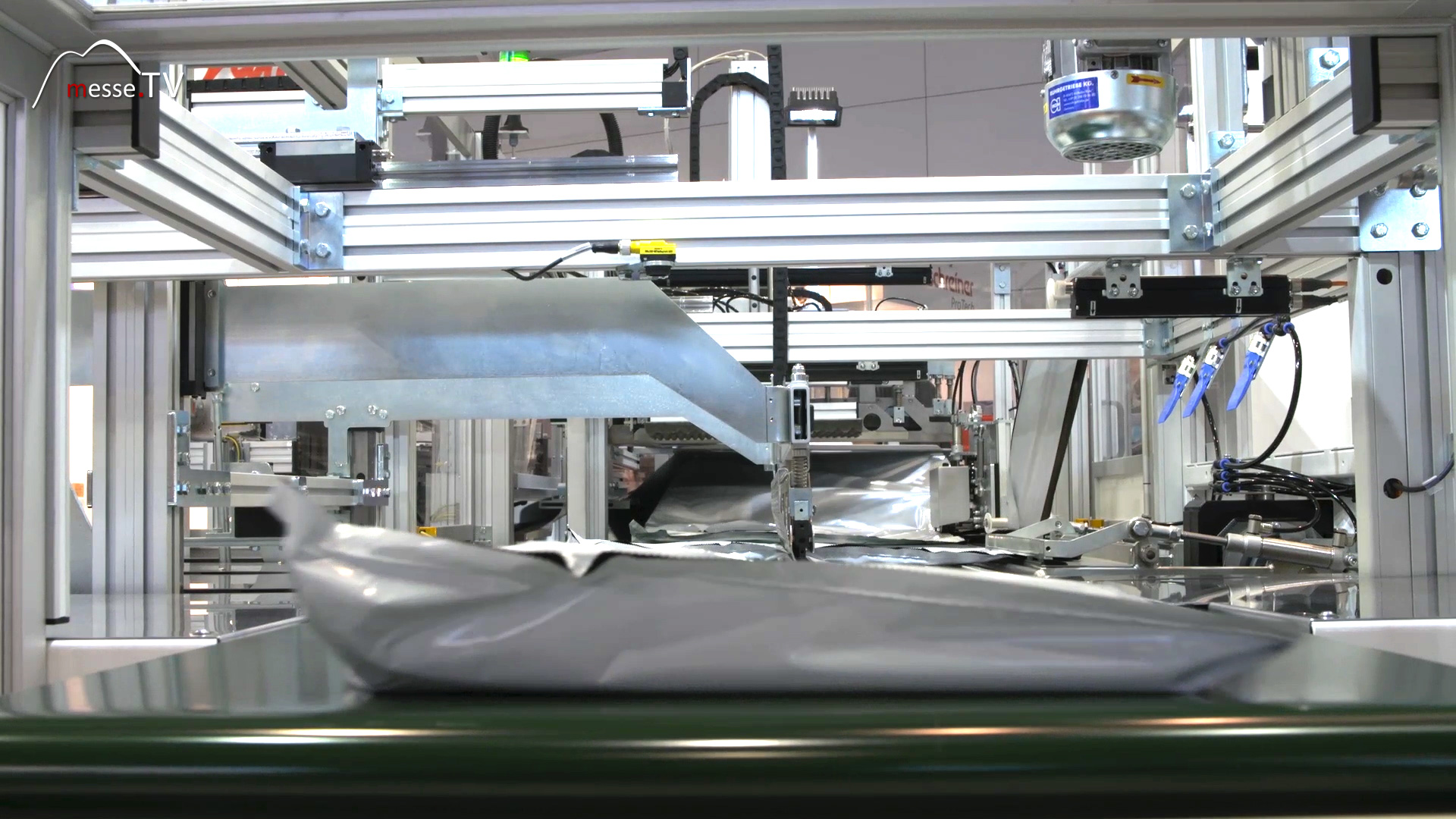

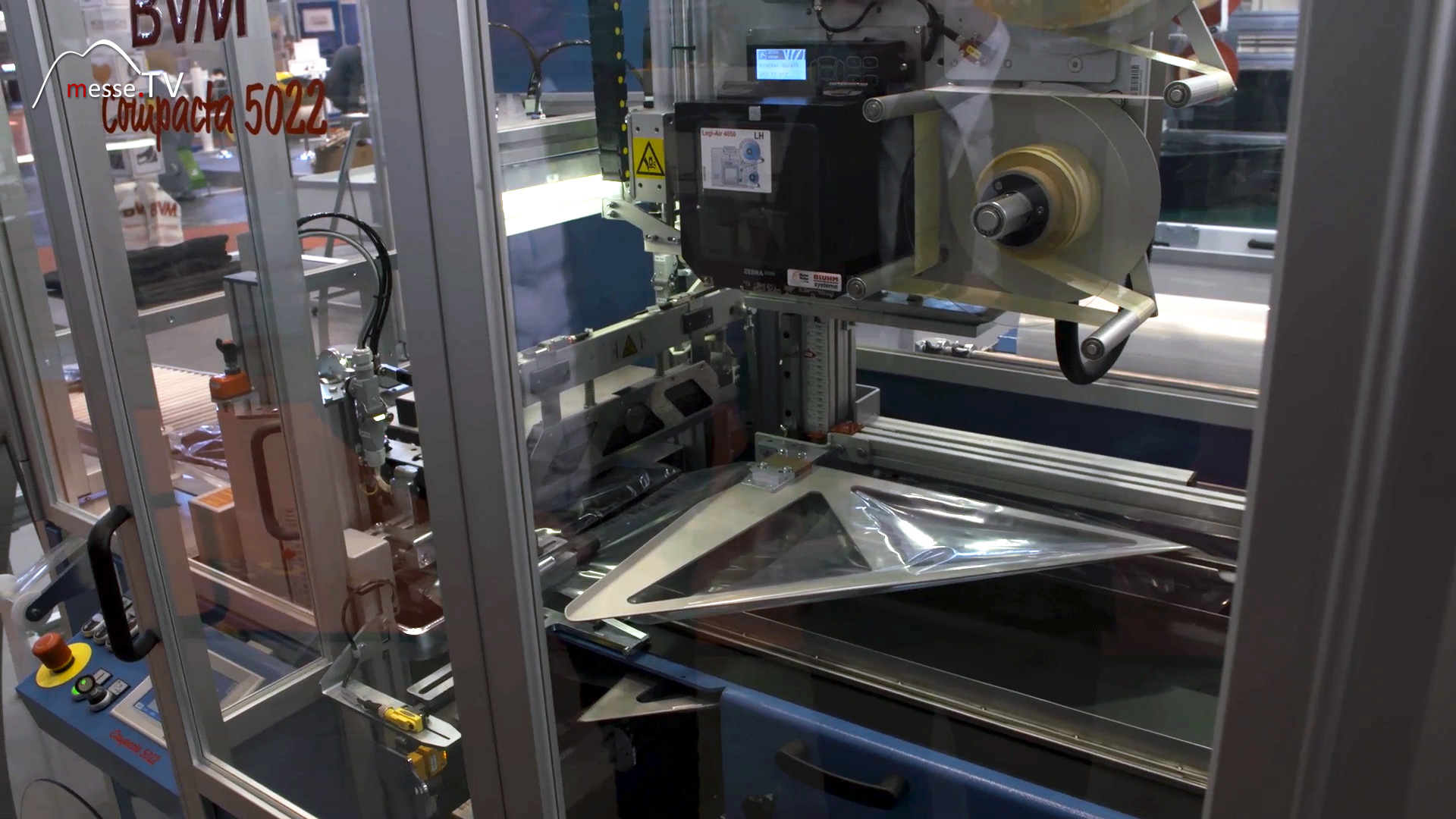

Klas Bömecke: And what is this great machine here? Dietmar Brunner: Well, we have a Comtex 4 G here. This is a dispatch line. The machine was originally developed as a returns machine for mail order companies. There, returns are repackaged right at goods receipt so that they can be sent out again as quickly as possible. We have developed the machine further as a dispatch machine. We work with colored film and labeling so that we can also apply an address label with a wide variety of carriers. Klas Bömecke: And do I always have to stack all the parcels on it in the same size? Dietmar Brunner: No. The machine can process different formats chaotically in alternation without the machine having to be specially set up for this. Klas Bömecke: Can you show me how the machine works? Dietmar Brunner: Yes, of course. So we place the delivery bill here and then the goods on top. (Mr. Brunner first places the note and then the goods on top - both continue on the conveyor belt) Klas Bömecke: And then it goes in there. The rest happens automatically in here. The label goes on there. (The foil is cut off and an address label is stamped on it)

Dietmar Brunner: Exactly, we drive through the machine flush right and always make a bag as wide as possible. Klas Bömecke: So it comes out the back here ready packed. Even with a handle flap. Dietmar Brunner: With a grip tab - always in the middle of the bag.

Klas Bömecke: That was quick. How many parts can you make in an hour? Dietmar Brunner: Yes, a maximum of 1500 packages. Klas Bömecke: How does the user benefit from using such a system? Dietmar Brunner: Firstly, of course, you save on shipping costs because the volume is much lower than if you send the goods in a box. And of course you don't have to keep different box sizes because you unwind everything from the film and cut the bag to the size of the product. Klas Bömecke: And the bag is always just as big as it needs to be? Dietmar Brunner: Correct! Klas Bömecke: That's great, of course! Both change the stand to a new machine.

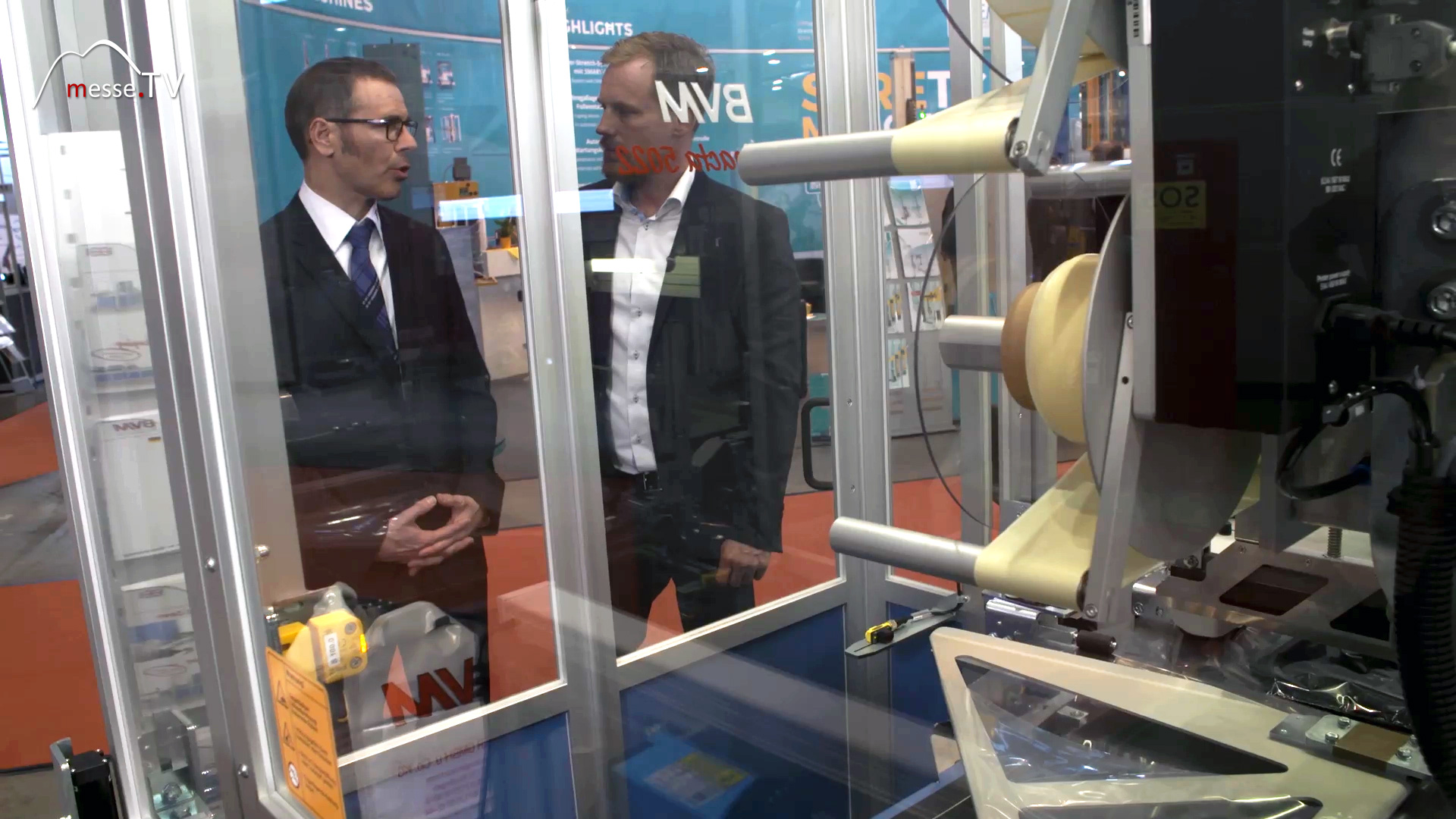

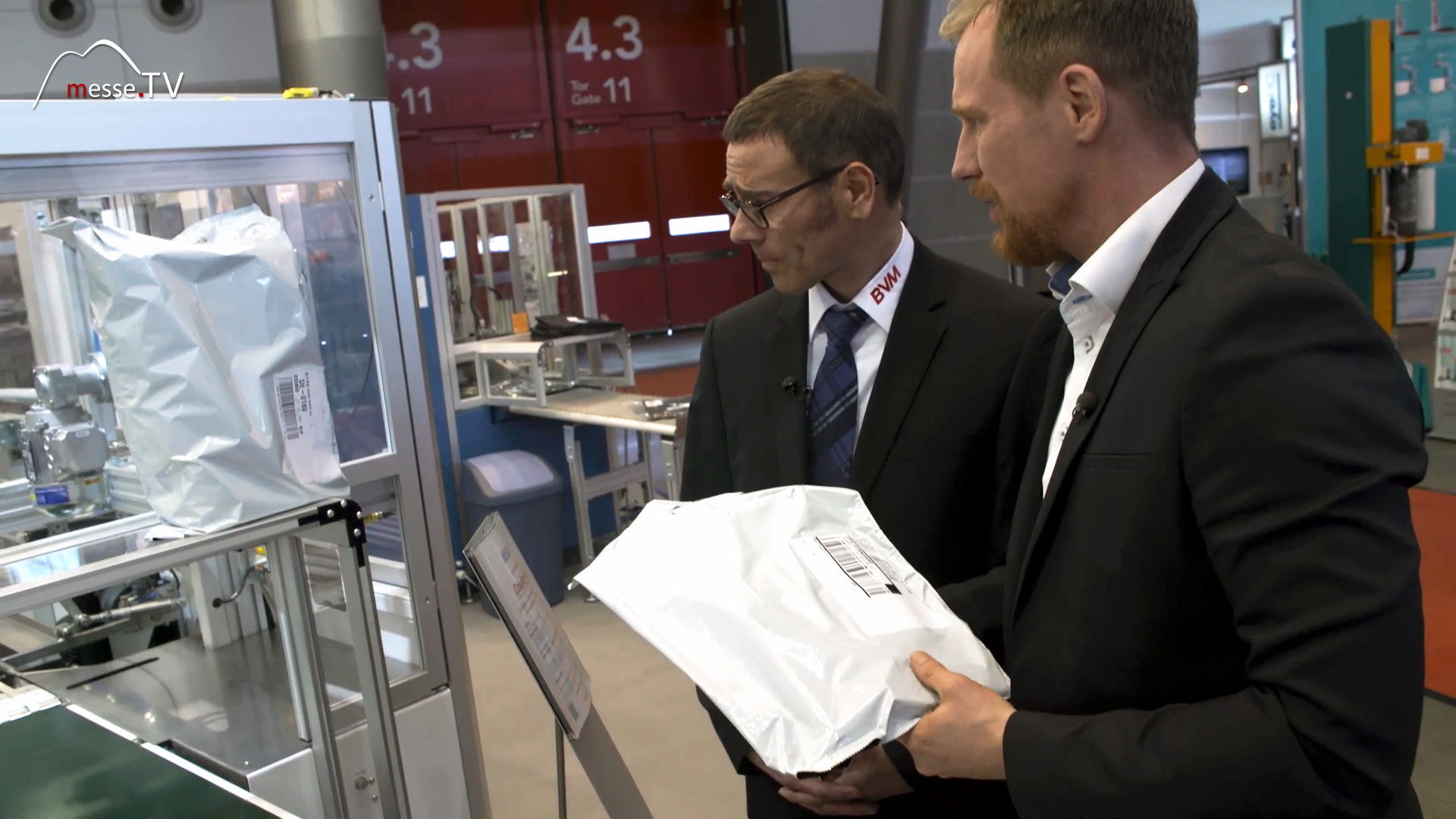

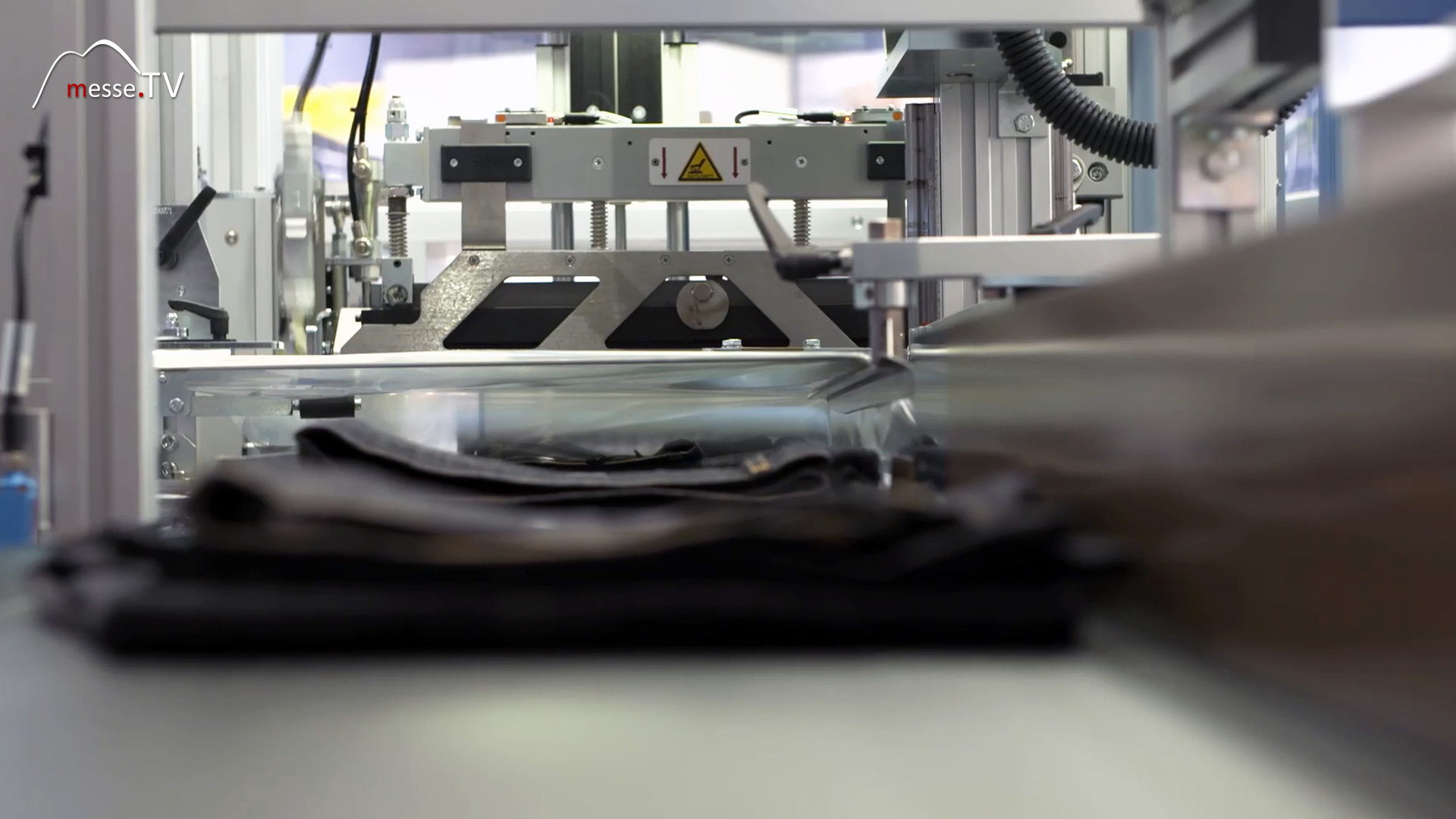

Klas Bömecke: What is that? Dietmar Brunner: So here we have a Compacta. A packaging machine with a barcode replicator. As a rule, goods come directly from overseas - in containers - and they have to be packaged. This means that there are already barcodes on the products, but they now have to be applied to the outside of the packaging so that the products can be stored ready for dispatch and also shipped. Klas Bömecke: So now there's a pair of jeans here. Is that how they arrive - with a barcode attached? Dietmar Brunner: Yes, this barcode is on the outside of the jeans and we need it on the outside of the packaging. That's when they are placed on the conveyor belt here and now we attach the barcode to the outside of the bag.

Klas Bömecke: And here it comes out perfectly packaged. This barcode is exactly the same as that? Dietmar Brunner: Exactly the same. Klas Bömecke But what's next in the future? Dietmar Brunner: Well, the plan for the future is to merge the invoice, delivery bill and goods in the line and ship them directly. Klas Bömecke: That means that when we meet here again in a year's time, I might see a modified machine that can do the same. Then I wish you lots of fun and success with the development and a great trade fair. Thank you very much Mr. Brunner. Dietmar Brunner: Thank you too.