Do you need maximum individuality in your sanding processes? Then you should pay close attention now. We are visiting WEMA Glauchau at GrindTec 2016. The machine tool factory promises made-to-measure suits instead of mass-produced suits. Anyone who can look back on 130 years of history is sure to have a lot to tell. We are excited and curious!

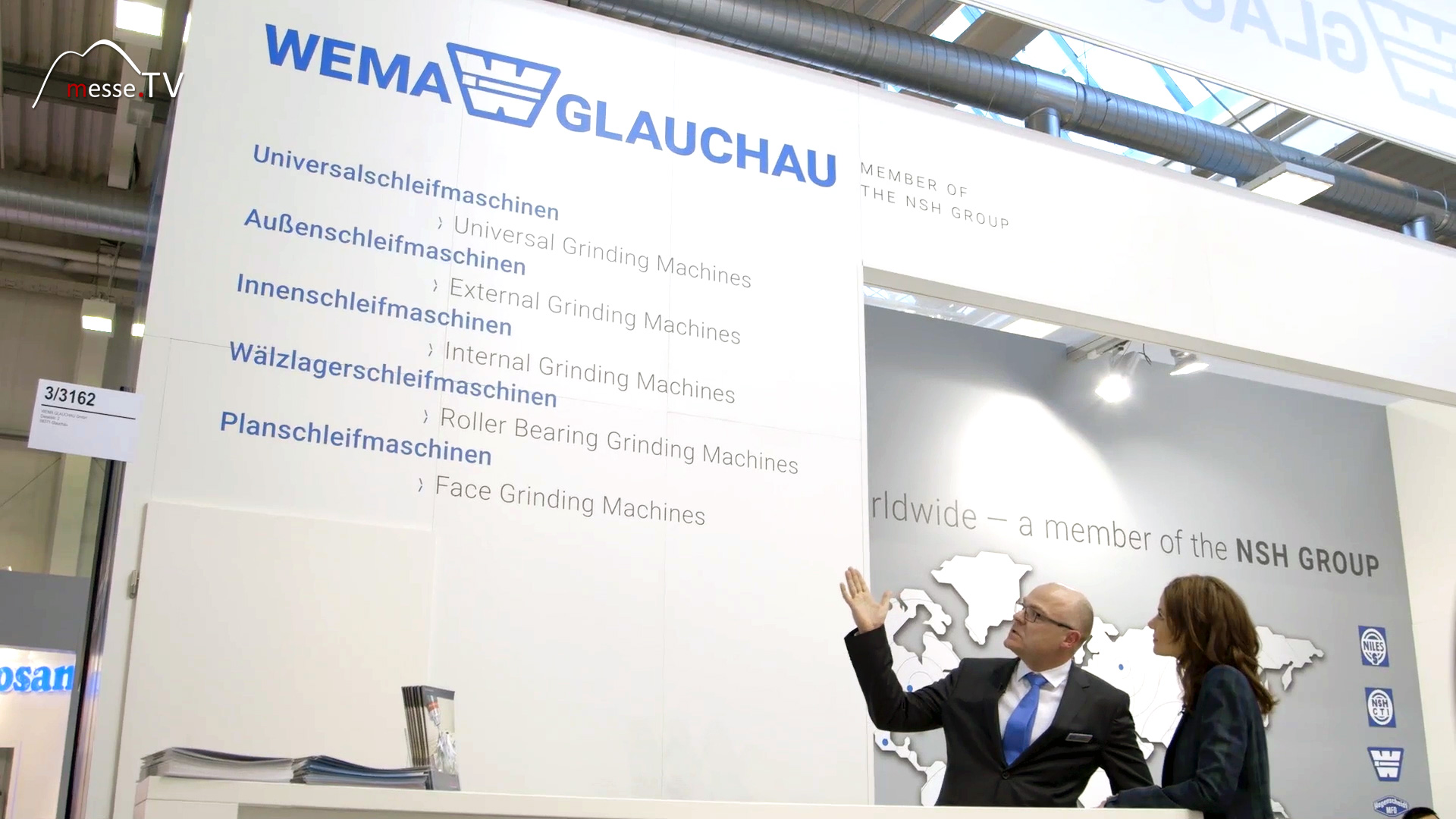

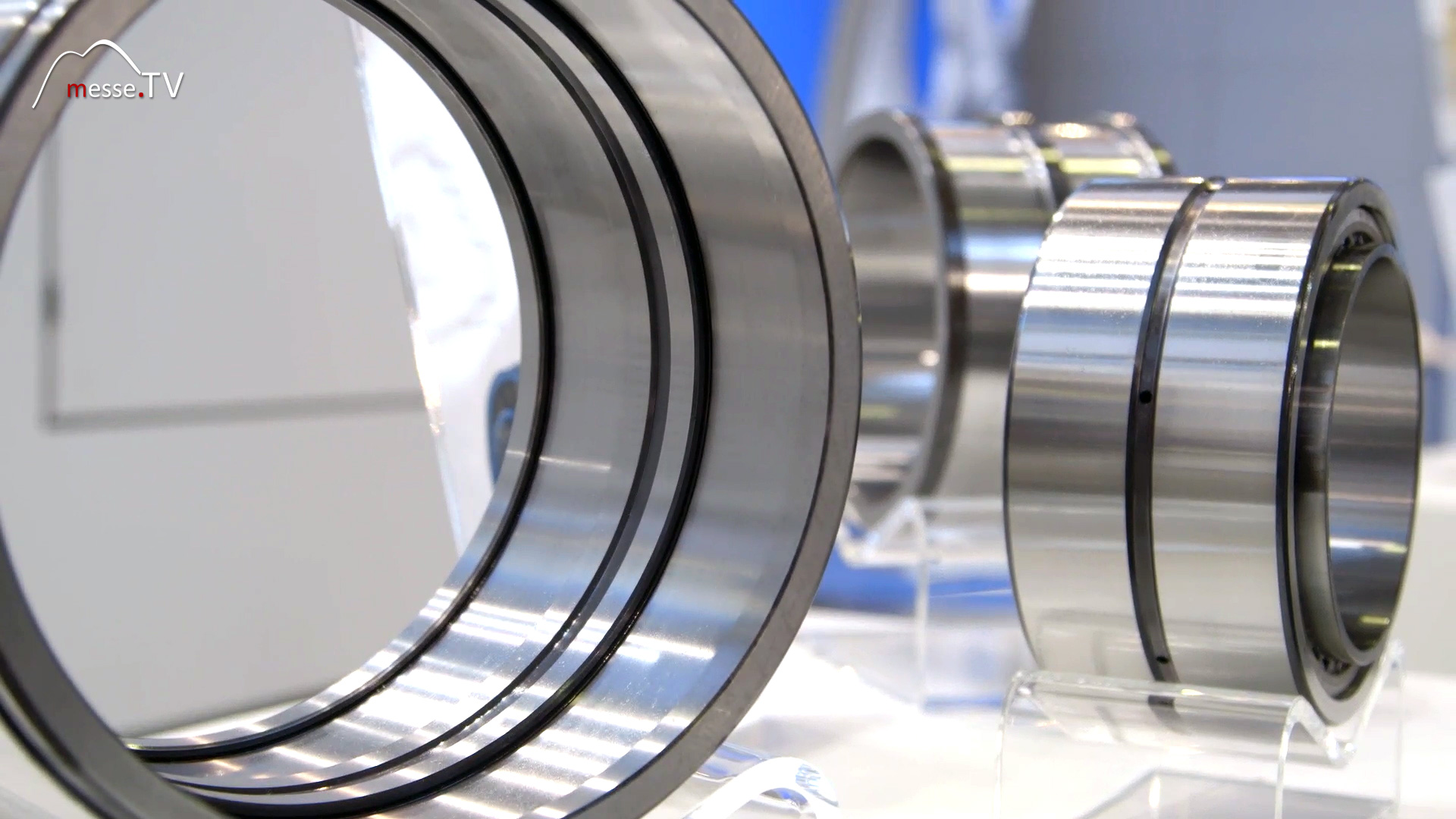

The company Wema Glauchau claims to offer made-to-measure suits and not mass-produced suits for a wide range of grinding processes. And let's find out whether these customized suits really fit. Simone Dericks: Yes, hello Mr. Krippendorf, we are now here at your stand at Wema Glauchau. What distinguishes your company? Ronald Krippendorf: Yes, a history that goes back a long way. More than 130 years - that's quite unique these days. We are characterized by a broadly diversified production spectrum as Werkzeugmaschinenfabrik Glauchau. In addition to universal machining, we also have external grinding machines and rolling bearing grinding machines, and at this point we can call customers such as SKF and Schäffler our own. As a company, we have been part of an internationally active group since 2013. This is the company NILES-SIMMONS-HEGENSCHEIDT. An internationally active group with many subsidiaries, including in China and the USA. We can use these branches to ultimately distribute our machines, our products, which are individually tailored to the needs of the customer, worldwide.

Simone Dericks: What is special about what you have for the customer? Ronald Krippendorf: With us, the customer gets a tailor-made suit, not a mass-produced suit. This means that the customer comes to us with a specific task, which is then evaluated. Based on this assessment, we offer the customer a machine tailored to their needs. Be it, for example, an internal grinding spindle, be it two, be it three, be it from that company or from another company, so that the customer's needs are always met. Simone Dericks: That means flexibility is also one of your great strengths. Ronald Krippendorf: That is one of the main strengths. Simone Dericks: You also brought a highlight to this trade fair! Ronald Krippendorf: Yes, I would like to present it to you now at our stand. Let's go around. I'll go first.

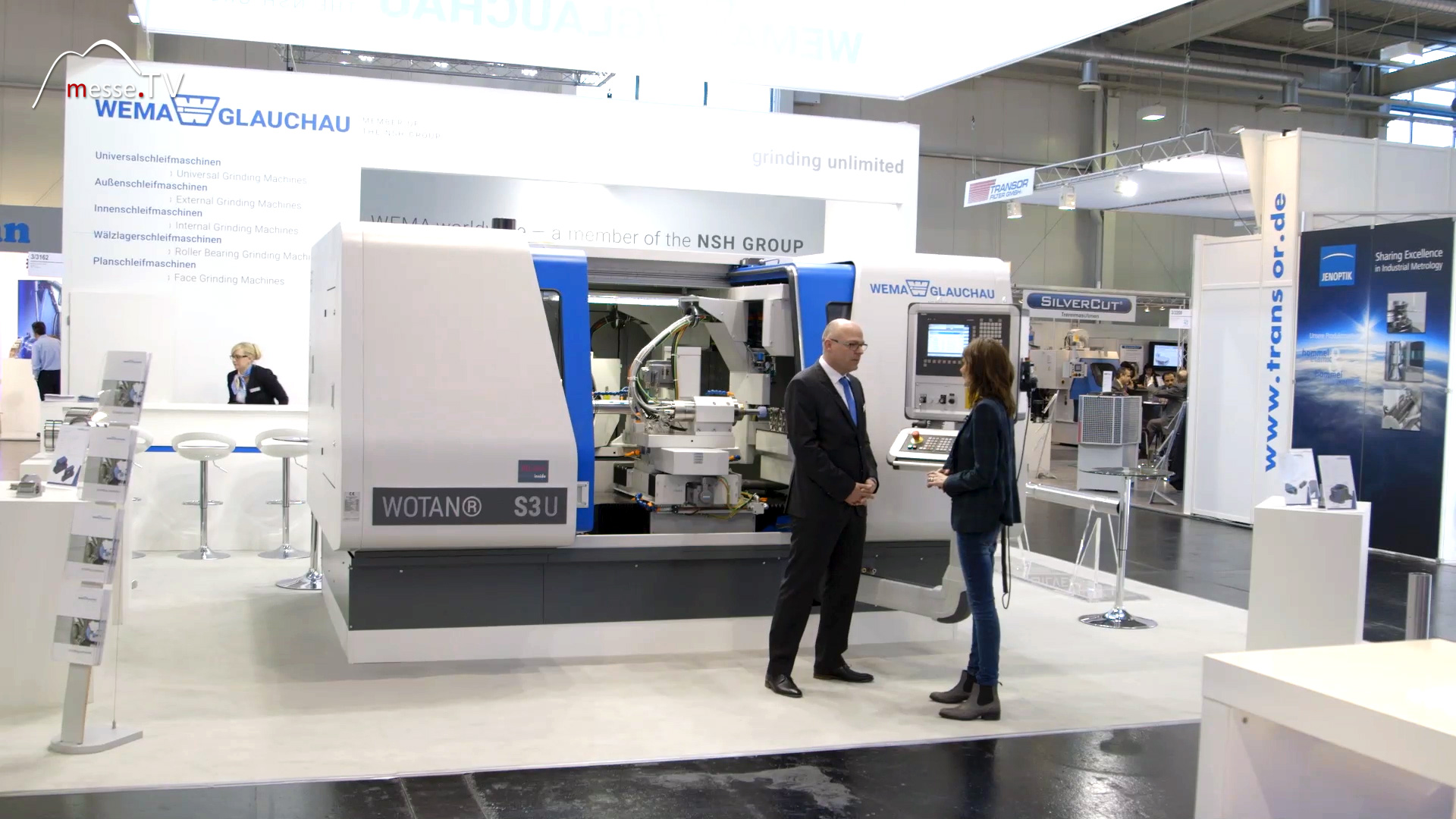

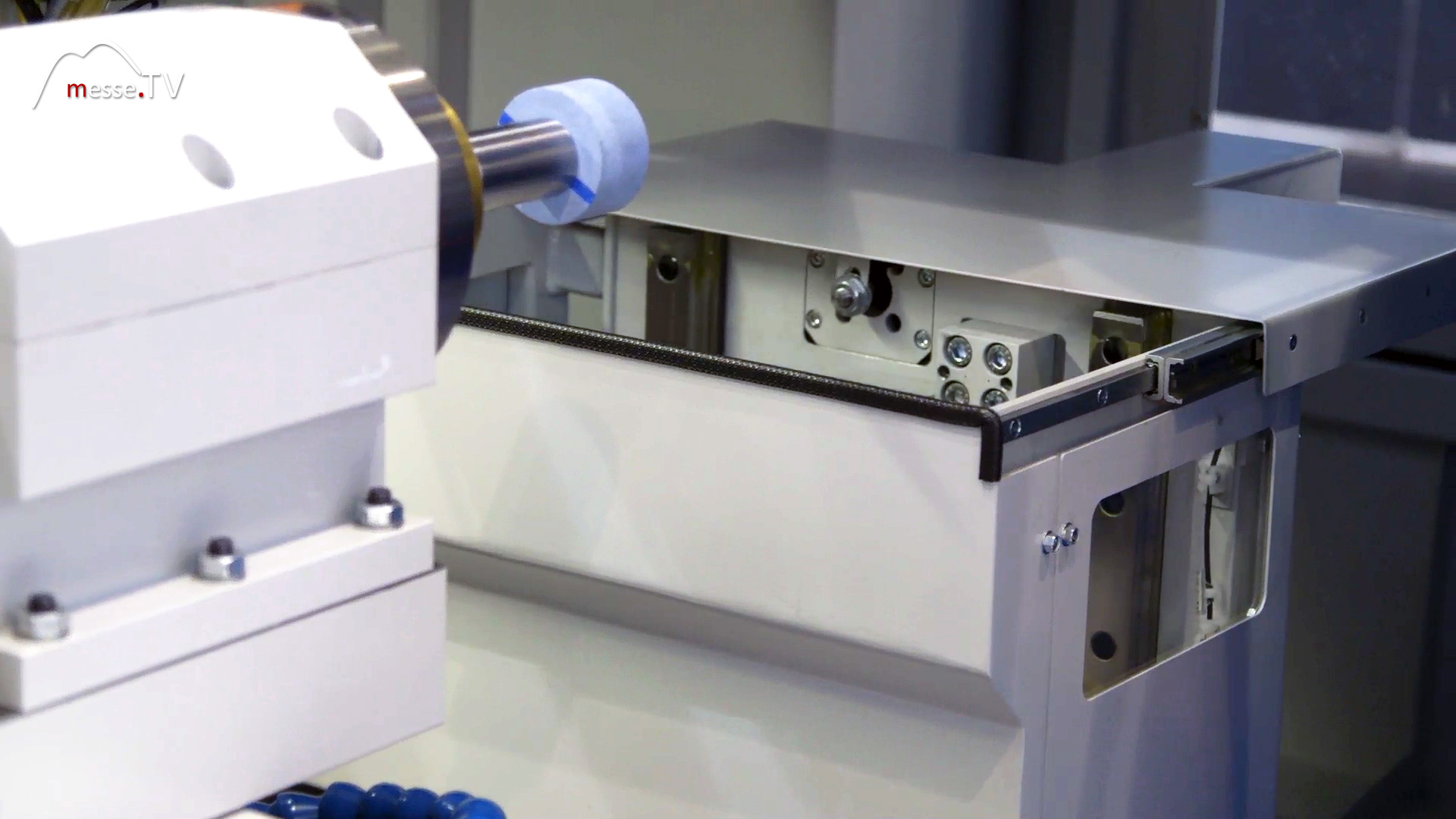

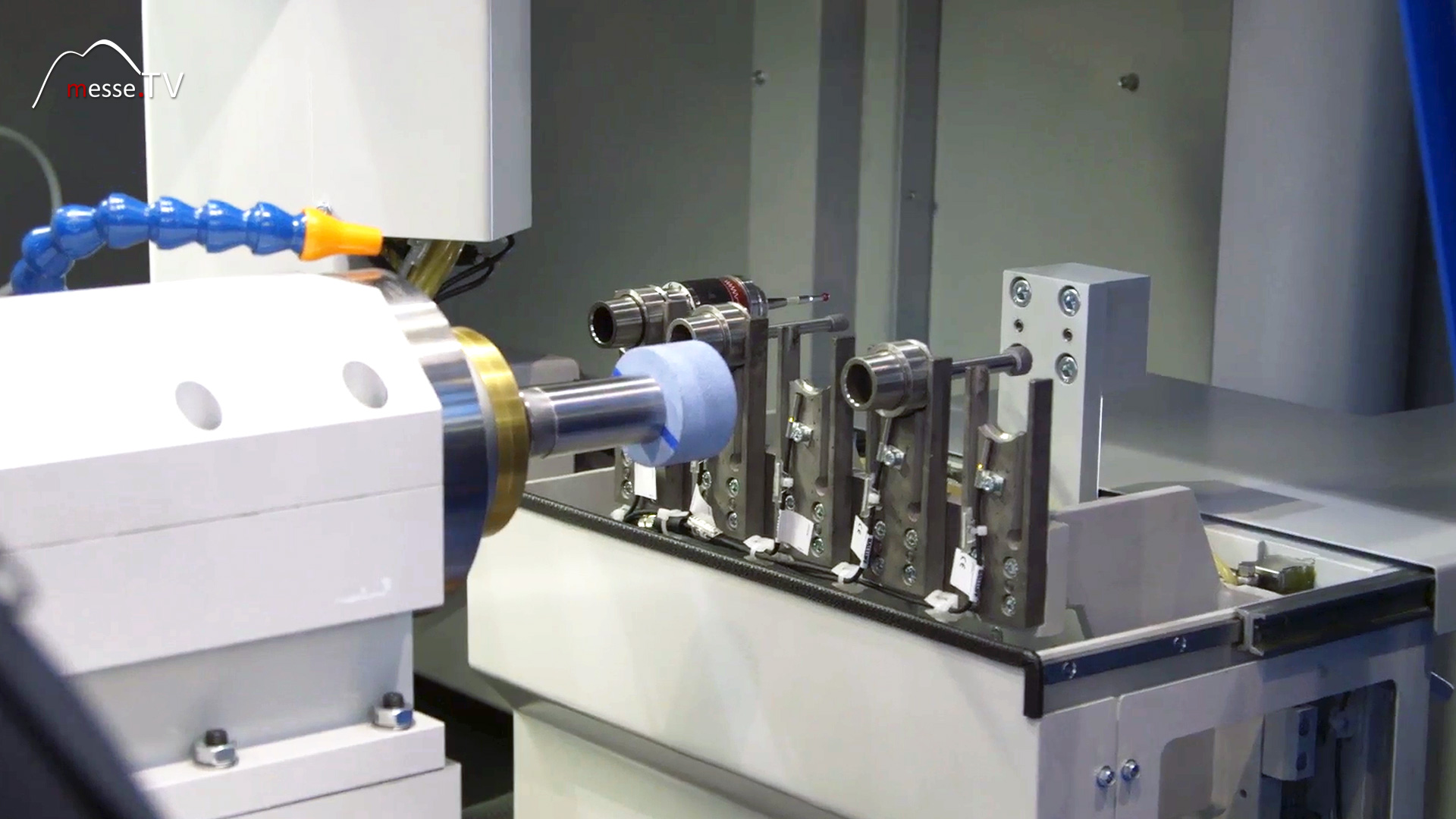

Simone Dericks: Yes, now we're standing here in front of your highlight. It all looks really spacey. What can this machine do? Ronald Krippendorf: It's not quite that spacey, but we'll explain a bit. Yes, our trade fair highlight is the Wotan S3U, which is a traditional name. Wotan, that's where the prehistory of our company comes from. And here at our trade fair, we have a machine with an integrated tool changer, so to speak, which means that we have significantly increased the number of tools available in order to be able to carry out complex machining processes in just one set-up. Simone Dericks: And this is very new, it doesn't exist in this form yet? Ronald Krippendorf: Well, we have done the following. We have already built a machine with 70 places for the tool changer and have also implemented this philosophy in the other machines, including the S3U. At that time it was an S6U where we implemented this for the first time.

Simone Dericks: How many tools can you use there? Ronald Krippendorf: Here we have the option of adding 5 more tools as part of our tool changer, which you can see here. As a result, we have now given the customer the option of implementing up to 7 tools in this machine, plus the tools that are attached to the external grinding unit. Previously, it was only possible to make 3 tools for internal machining and now we have 7, but this could also include tools for measuring, not just grinding. We have also implemented processes for machining. Drilling a small hole, for example.

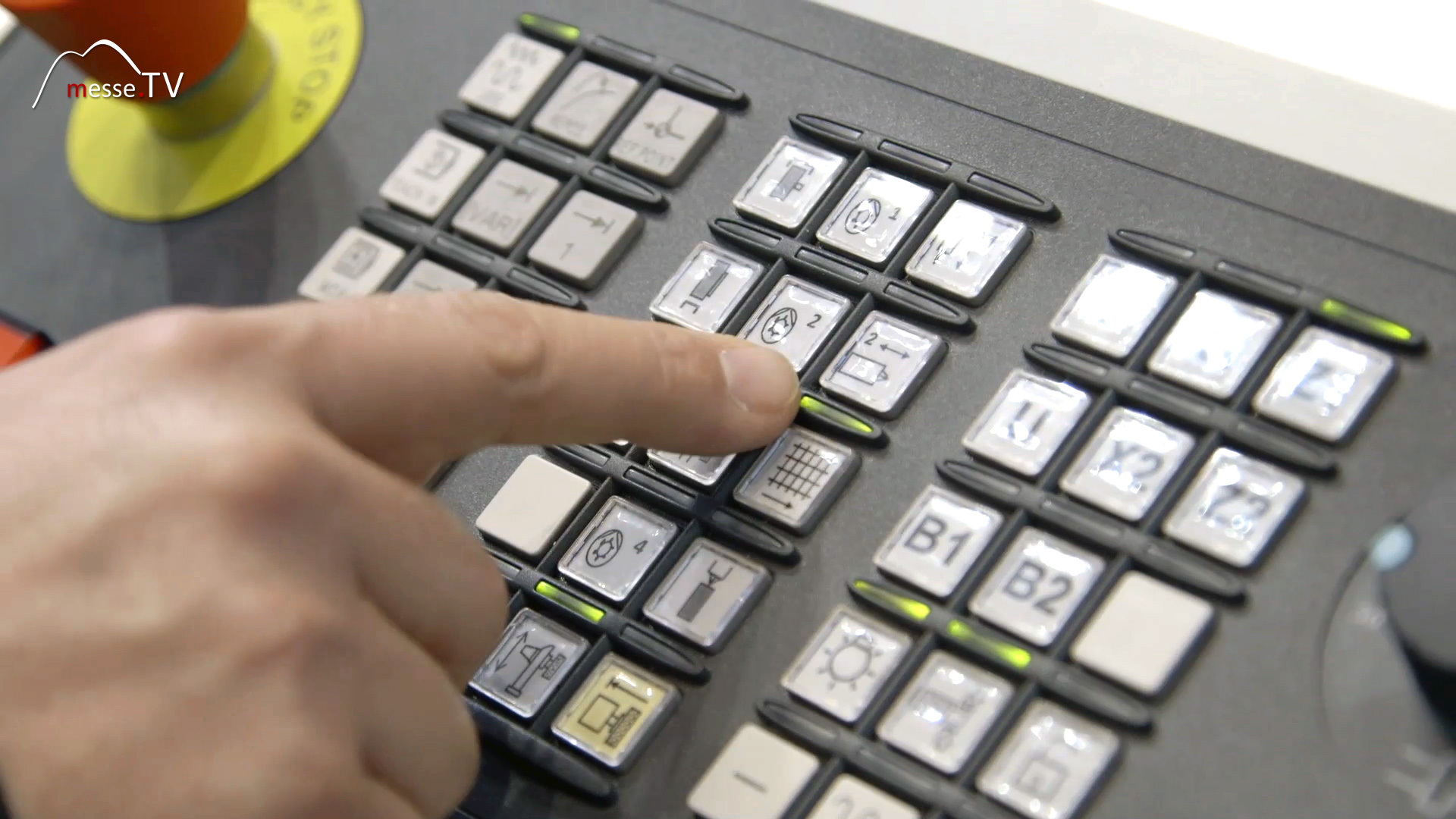

Mr. Krippendorf presses the button on the S3U and the tool attachments move up. Ronald Krippendorf: Here you can now see the range of tools that can be implemented. There are 5 slots here. We need one slot for changing tools and the others can then be used accordingly. This is - it's fair to say - a major innovation at this trade fair, which no grinding machine has implemented to date. Simone Dericks: And in what sizes do you have the Wotan machines? So what is available from the small parts to the large ones? Ronald Krippendorf: We can machine components in a so-called two-series with a swing diameter of up to 200 millimetres. All the way up to the 6 series, where we can create orbital diameters of up to 600 - 700 millimeters.

Simone Dericks: And since this is so new, we don't want to talk about the future, but let's just do that now. Where do you see yourself in 1-2 years' time? Do you think there will still be innovations that you can present then? Ronald Krippendorf: Yes! We will still see key points, especially in this area of Industry 4.0, which will play a major role. We are already holding the first talks with end users, well-known users in the field of factory storage technology, and we will see great leaps in this area. Simone Dericks: Thank you for talking to us. Ronald Krippendorf: Thank you very much! Have a nice day!