Innovative solutions in the field of grinding technology - that's what Kirner promises. The traditional company can look back on almost a hundred years of history and has established itself as a global leader with its 6-axis kinematics. Presenter Simone Dericks has Managing Director Martin Kirner show her the trade fair innovations at GrindTec 2016.

The six-axis kinematics - I'm sure the term means something to you. The Kirner company from Neustadt am Titisee has been a world leader in this field for many, many years. Now, here at Grindtec, they have brought something completely new with them. And I'm going to see what it is! Simone Dericks: Hello Mr. Kirner, I've landed with the boss himself. Tell me, what does your company actually stand for? Martin Kirner: Kirner stands for innovative sanding technology - for modern dressing concepts. We also manufacture dressing machines. We do all this at our site in Titisee Neustadt, in the Black Forest, and we are very pleased to be able to present this machine, the 366 CNC, here.

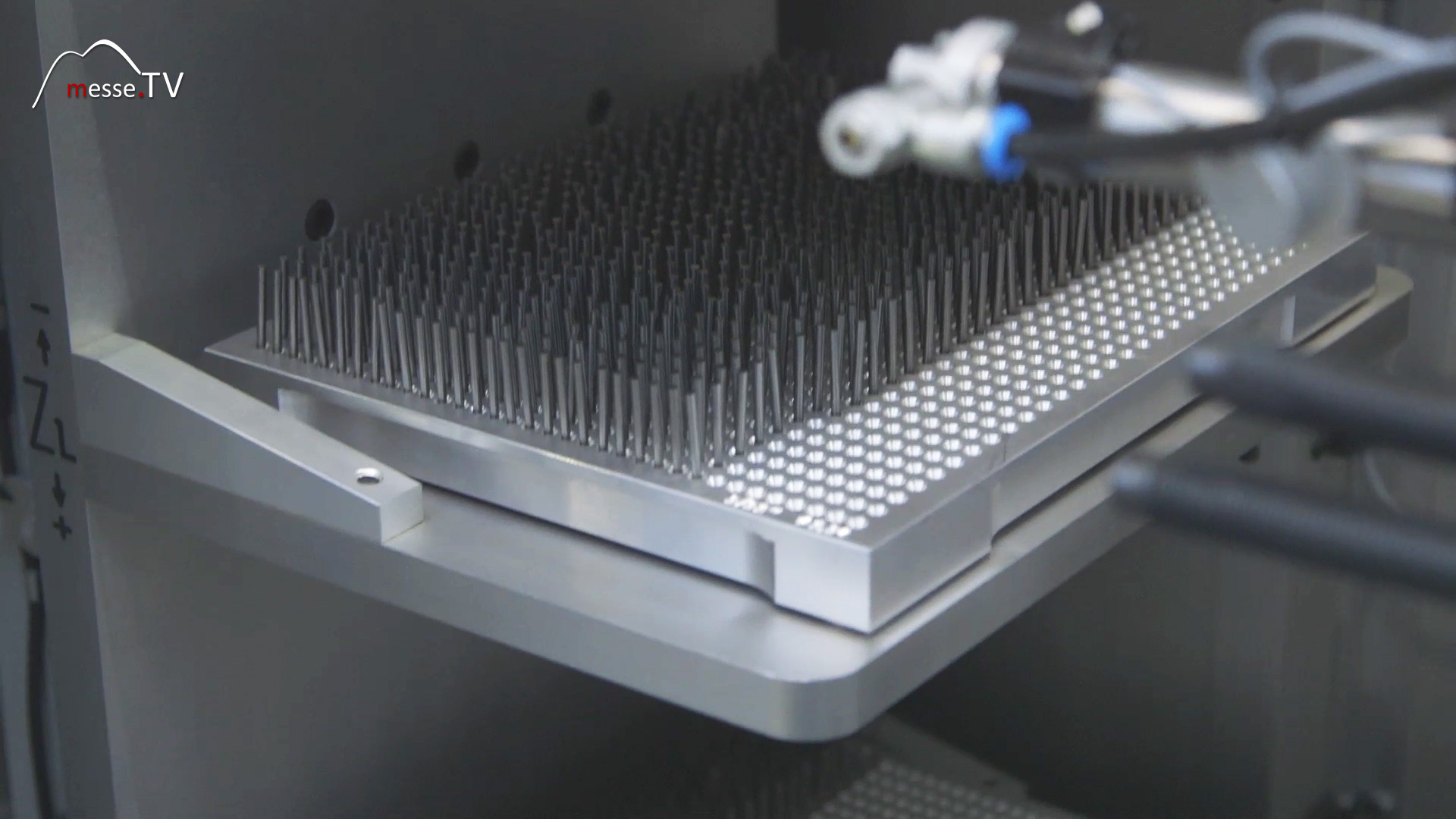

Simone Dericks: This is the machine behind us and what exactly does it do? Martin Kirner: We can use this machine to produce small milling tools for the dental industry or dental supplies. Let me show you! Mr. Kirner holds both metal pins (milled and unmilled) in his hand Simone Dericks: But it's very delicate. Martin Kirner: We have developed a special axis kinematics for this, but it's not entirely new, we've been using it for many decades. A workpiece like this is produced with 6 axes, and we have cylindrical grinding operations in a record time of just one minute. The actual grooving is all done on this machine in a single clamping operation. And we can stock this automatically. We also have a placement system here that you can see. Up to 2,000 workpieces can be stored here. Here we can see the blanks all clamped. The workpiece changeover time, i.e. the interruption of production, is only 7 seconds. This gives us a highly efficient machine that works around the clock.

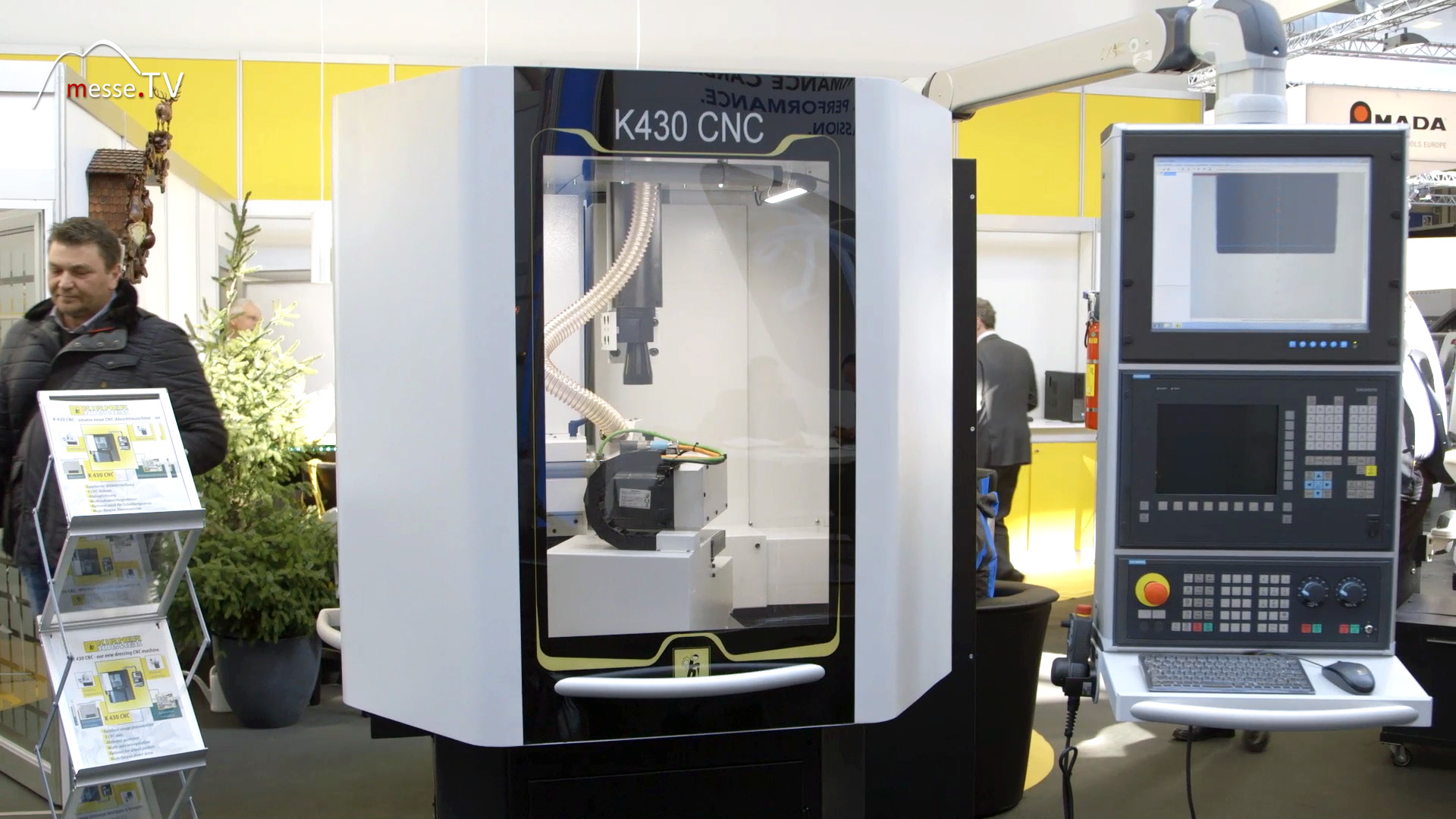

Simone Dericks: What is so special about the Kirner machines? What do customers get from you that they don't get elsewhere? Martin Kirner: At Kirner, you get optimum support. This means that we have a tradition of very close customer contact for many, many decades. We do a lot from within our own company. That means we also visit our customers worldwide. We have the entire core competence here on site, which means we have the grinding technology, the automation technology and the actual design. It's all united under one roof. Simone Dericks: You have also brought a highlight to the trade fair this year. What is it exactly? Martin Kirner: It's a CNC dressing machine. Perhaps we can take a look at the machine.

Martin Kirner: Nothing is actually produced on this machine per se, grinding wheels are dressed on the machine. This means that a diamond grinding wheel, for example, which is used on a tool grinding machine, wears out and we have to correct this wear. In other words, our customer does this by dressing or profiling a certain contour. This is used synonymously. This gives them a sharp wheel that can then be used for grinding again. Simone Dericks: So this machine simply takes the work out of the process. Martin Kirner: Yes, it is essential that you always have a good wheel, a good tool, when grinding tools. And you also need a good dressing machine. In this case, the 430 CNC, which we are presenting here for the first time at the trade fair. It can be used for semi-automated CNC dressing. This means that the CNC program for the movements via the motorized axes is no longer manual. We also have a direct drive in the central axis. This means that it carries out all the movements with practically no or very little wear, which gives us a very fast result. And this machine is equipped with a camera monitor system. High end.

Simone Dericks: Is there anything else coming up in the next few years? Martin Kirner: We have something up our sleeve, it's a ZIM-funded project that we are carrying out together with the Schwenningen branch of the university. I can reveal this much: it's about laser dressing. Simone Dericks: That's great. Then I'm curious to see if you'll be here at Grindtec next year with the "new" device. Martin Kirner: We'll give it a try. Then again next year.

Simone Dericks: Or the year after next! For now, I wish you every success and thank you for a great trade fair! Martin Kirner: Thank you and goodbye.