At IAA Mobility, Magna is putting the spotlight on sustainability. The company is presenting a broad portfolio of materials and technologies that focus on resource conservation, recyclability, and new manufacturing processes. These solutions are complemented by developments in energy storage systems and vehicle structures that are specifically designed for electric drives.

Magna has observed that automotive manufacturers are increasingly using sustainability as a differentiating factor. That is why the company is presenting components at IAA Mobility that contribute to this goal. A seat concept made of monomaterial illustrates the approach: the car seat is made entirely of one material and can be easily shredded after use and reused for production. This creates a closed material cycle – an old seat becomes a new one.

Magna is also focusing on the circular economy for drive components. Transmission housings are made from recycled material or refurbished to make them usable again. Old housings thus serve as the basis for new products, while refurbished transmissions are reused in current vehicles. This reduces energy consumption and raw material requirements. With the Aural 5 and Aural 2 alloys, Magna showcases recycled aluminum materials that are processed in high-pressure die casting. A front-end component with 25 percent recycled content demonstrates that sustainability and high quality standards are not mutually exclusive: there are no visual or structural limitations.

In addition to metal, Magna also relies on renewable raw materials. A door carrier, the Sustainable Door Carrier, is made from hemp. The material is 20 percent lighter than plastic and four times as impact-resistant. Another example is the Roof Rack Inner, the interior of a roof rack, which also contains hemp. Here, the natural fiber content is ten percent. Such solutions show how weight can be reduced while increasing stability.

With embedded eco-design, Magna is demonstrating an approach that goes beyond the choice of materials. Even in the development phase, the focus is on the question: How can a component be dismantled and recycled at the end of its life cycle? This engineering approach is designed to ensure that products are not only produced efficiently, but can also be recycled efficiently.

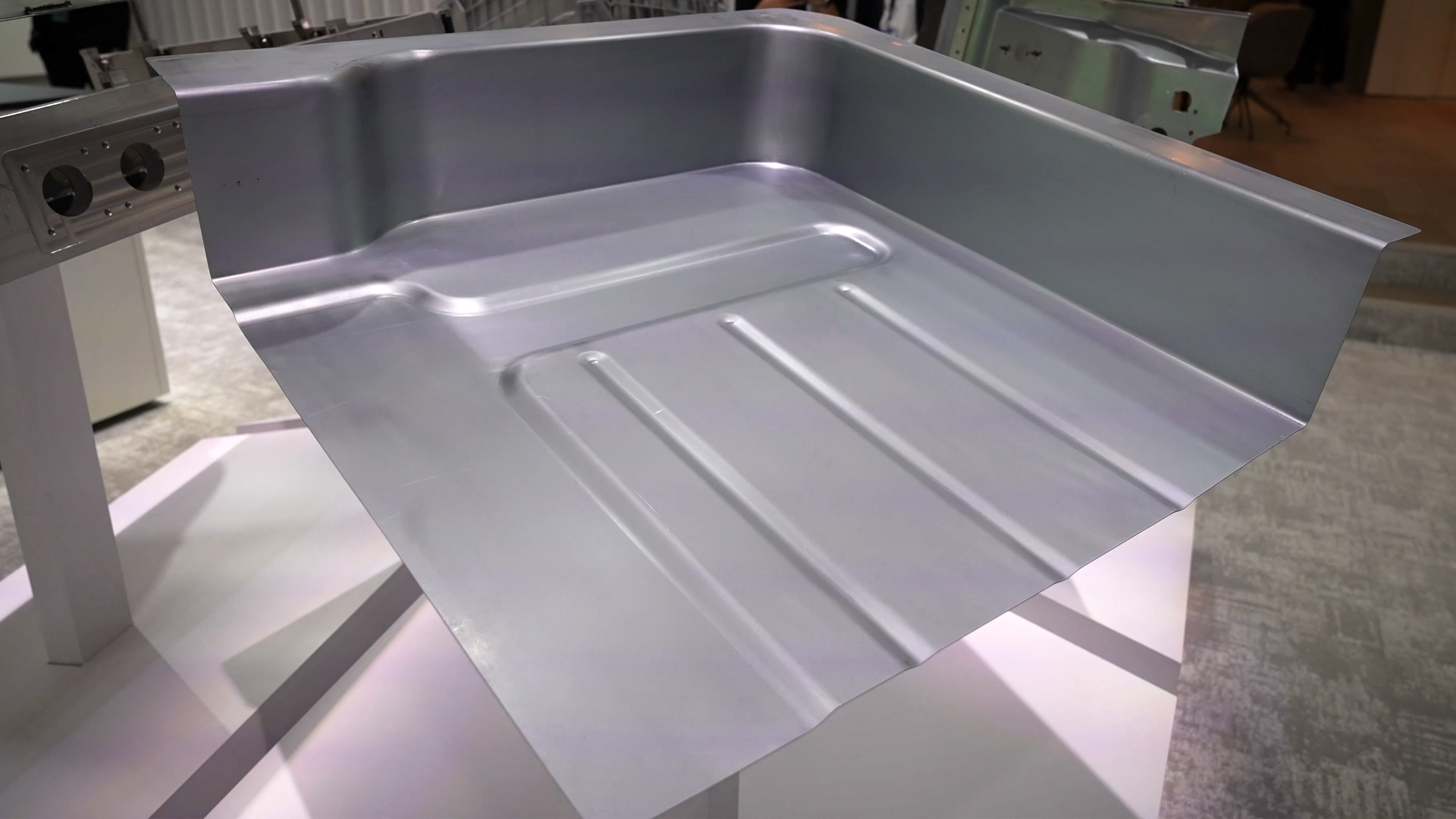

A second focus is on energy storage systems. Magna is presenting various battery trays, including a hybrid tray made of cast aluminum and a multi-material tray that is also designed for structurally relevant applications. The Optiform process creates a battery carrier made of sheet metal that eliminates sealing problems and creates additional space for battery cells thanks to steep walls and sharp radii. The portfolio is complemented by trays with integrated reinforcements that meet the increasing demands for stability.

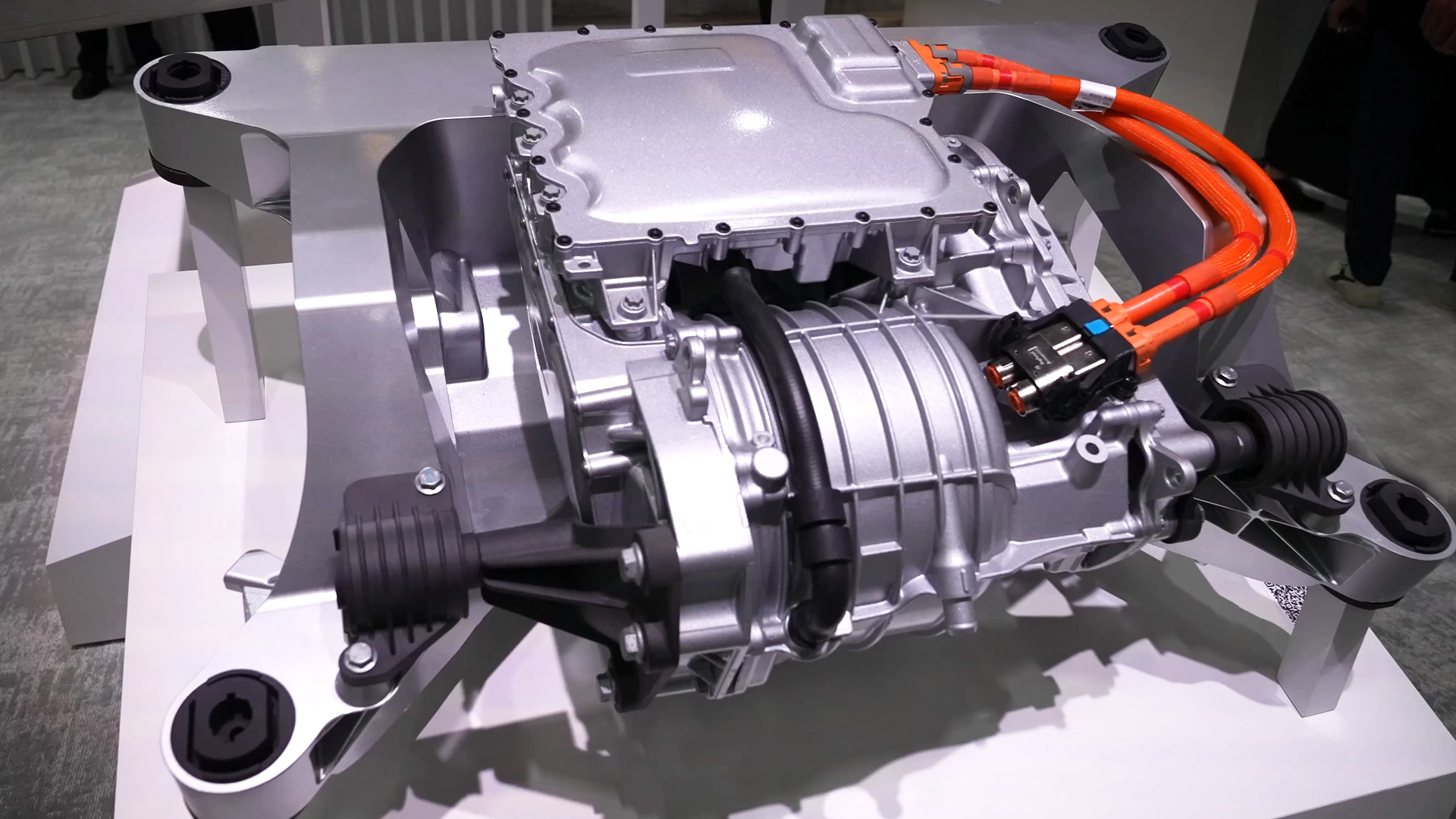

Another highlight presented by Magna is the E-Cradle, a subframe developed specifically for electric vehicles. It is around ten percent lighter than conventional variants because it is made entirely of cast aluminum. The design optimizes the installation of the electric drive: it requires less installation space, facilitates access to individual components, and simplifies assembly. This is made possible by the combination of drive and body construction expertise that Magna brings to the development process.

These examples illustrate that Magna sees sustainability not as an add-on, but as an integral part of its development strategy. From monomaterial seats to recycled aluminum components and hemp composites to optimized battery carriers, the company is demonstrating at IAA Mobility how ecological requirements can be combined with technical performance. This gives automotive manufacturers a clear competitive advantage.