Inocon Industrial Plants is an internationally active company specializing in the planning, development, and implementation of complex industrial plants. The focus is on individual, technically sophisticated solutions for mechanical and plant engineering where standard concepts are not sufficient. Inocon accompanies projects from the initial concept phase through engineering and manufacturing to commissioning and sees itself as a long-term technology partner for its customers.

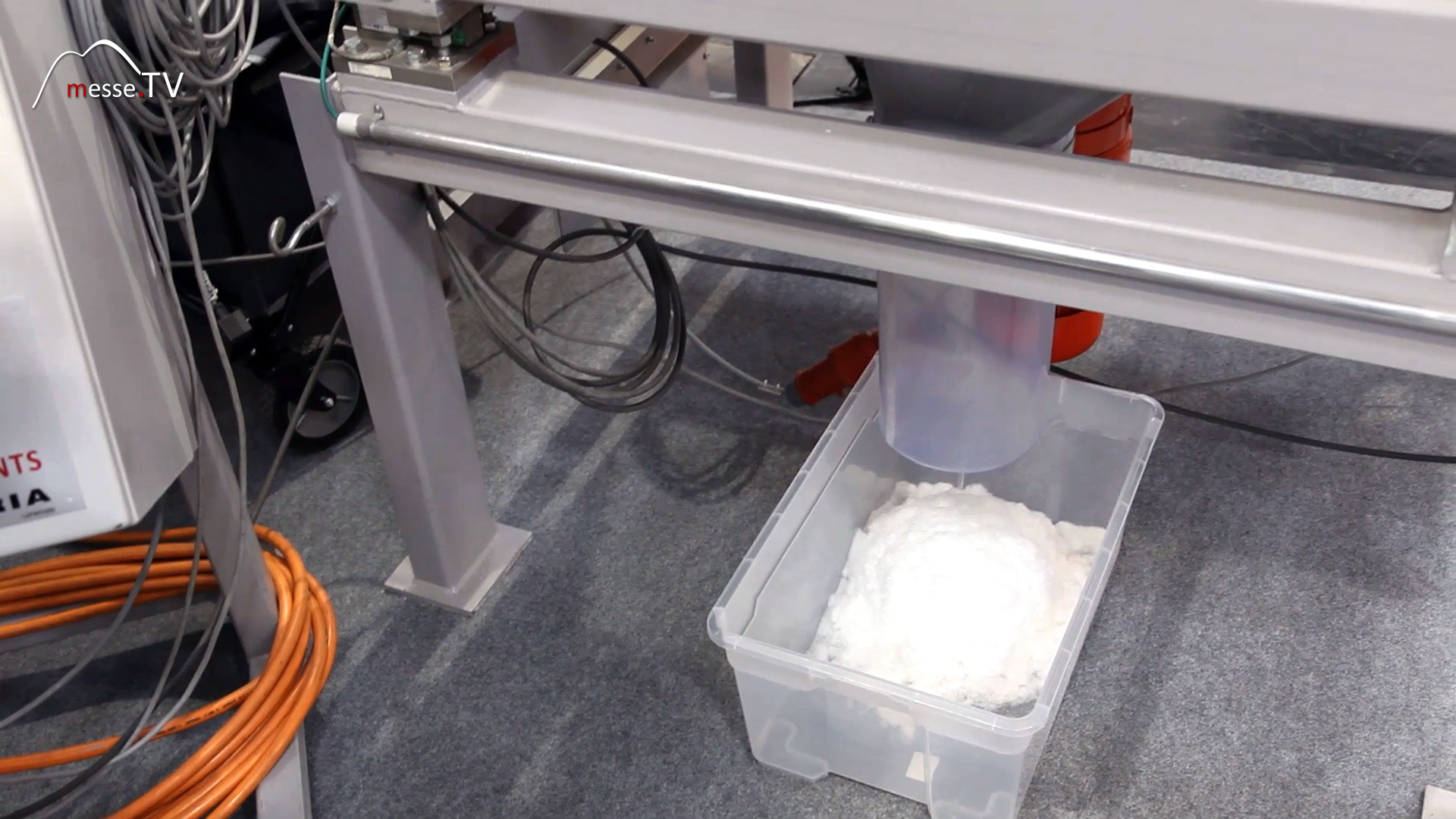

Since its foundation in the early 1990s, Inocon has focused on special machines and automated plants that are precisely tailored to customer-specific production processes. Instead of supplying series machines, the company first analyzes the respective requirements in terms of material, process stability, throughput, and quality. On this basis, solutions are developed that can be deeply integrated into existing production environments. A particular focus is placed on the precise dosing and processing of materials, for example in fiber, powder, or additive systems. Such applications place high demands on mechanics, control technology, and process reliability. To meet these demands, Inocon combines mechanical engineering, automation, and software into closed systems that enable reproducible results and high plant availability. Typical areas of application for Inocon systems are:

Inocon works across industries for customers in manufacturing, energy, chemicals, metal processing, and other technology-driven sectors. This diversity is reflected in the technical breadth of the projects it has implemented. In addition to mechanical design, control and regulation technology, sensor technology, and digital interfaces play a central role. The aim is not only to map processes mechanically, but also to make them transparent, controllable, and optimizable in the long term. Close cooperation with clients results in systems that are precisely tailored to production targets, quality requirements, and operational conditions. Changes in the process or new product variants can often be taken into account as early as the planning phase, which minimizes subsequent adjustments during operation.

INOCON Industrial Plants

The company Inocon builds industrial systems for a wide range of industries. At bauma 2016 in Munich, Harald Bartel from Inocon will be showing a mach... Automatic fiber dosingA central theme in plant development at Inocon is the efficient use of resources. This includes material-saving processes, energy-optimized drive concepts, and durable machine components. Sustainability is not viewed in isolation, but is understood as an integral part of economically stable production systems. Plants that operate with precision and reduce waste also contribute to environmental and cost targets. Inocon continuously invests in modern manufacturing technologies and the further development of its engineering expertise. Close networking with research and development enables new technical approaches to be transferred to industrial applications at an early stage. With this claim, Inocon positions itself as a specialized supplier for sophisticated special-purpose machine and plant engineering, with a focus on technical depth, reliability, and individual solutions.