Ultre free internal pressure forming revolutionizes lightweight construction and vehicle design

by A. Bergmeier - 2025-10-14Ultre is revolutionizing lightweight construction with free internal pressure forming, fundamentally rethinking lightweight construction and vehicle design with Ultre free internal pressure forming. The technology enables ultra-lightweight yet highly stable structures to be created without the use of conventional pressing tools, opening up new design freedoms in vehicle design. Ultre is thus demonstrating how free internal pressure forming not only makes lightweight construction more efficient, but also more versatile in terms of design – from load-bearing automotive structures to near-series vehicle concepts.

For two decades, Ultre has been working on a technology that has the potential to fundamentally change lightweight construction: free internal pressure forming. What began as an experimental process in furniture construction and design has developed into an industrially proven method for highly complex, ultra-lightweight structures – even for applications in automotive engineering and aerospace.

From design to engineering – the development of free internal pressure forming

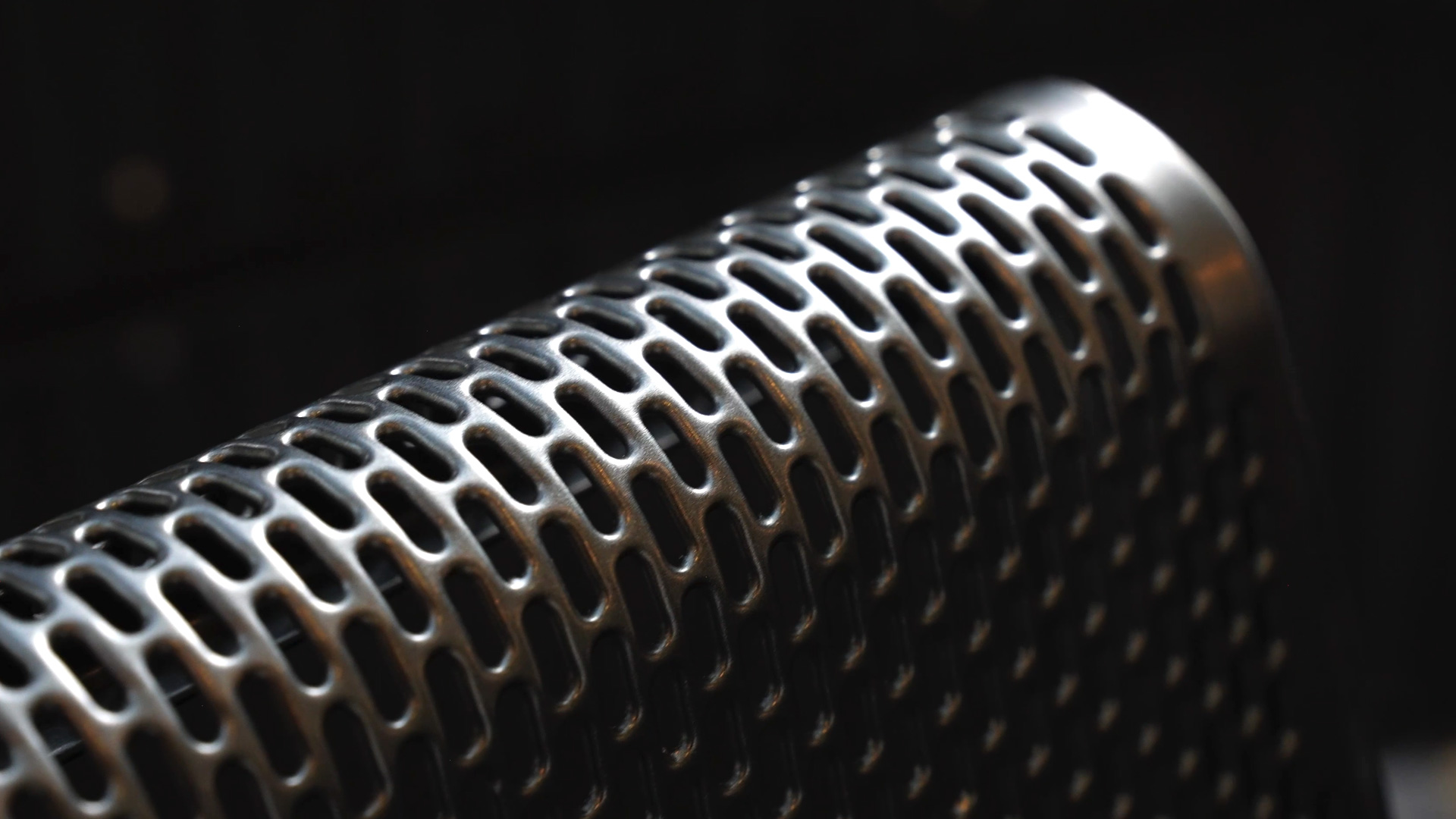

The technology originated in creative experiments with thin-walled sheet metal. Instead of pressing it with heavy tools and punches, as in classic forming technology, Ultre uses the physical effect of internal pressure. A flat metal structure is filled with a medium that expands when heated – the material inflates in a controlled manner, takes on a complex shape and solidifies in this form. This creates organic-looking, bionic structures that are extremely stable despite their low weight.

This method has been refined over many years. After countless simulations, manufacturing tests, and 3D scans, Ultre was able to refine the process to such an extent that components can be manufactured reproducibly and with high dimensional accuracy. Today, the company can produce ultra-lightweight, rigid, and dynamically resilient sheet metal structures – “printing instead of pressing,” so to speak.

Use in the automotive sector – ultra-lightweight structure with enormous load-bearing capacity

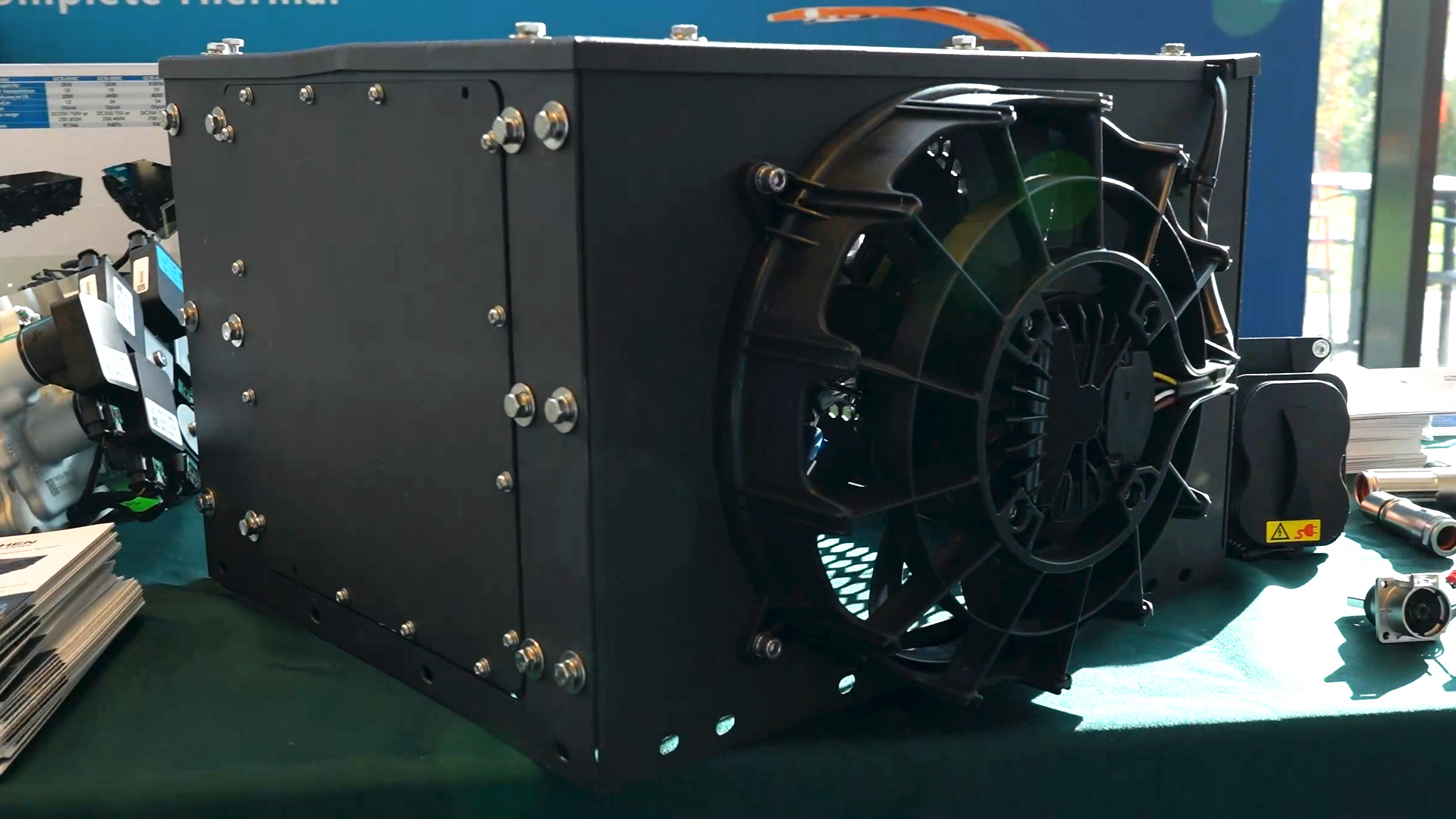

Ultre is now testing free internal pressure forming in vehicle construction for the first time. Chassis components were manufactured, tested, and crash-tested under realistic conditions. One example: a formed element weighing only 1.6 kilograms can withstand a load of over 1.2 tons. This combination of lightness and strength opens up new possibilities for car body structures, chassis, and safety zones – wherever weight reduction is crucial. The expertise also flowed into a market-ready vehicle concept: the Ultre 4 Cargo, an ultra-light transport vehicle for the urban “last mile.” The transporter weighs only around 600 kilograms but offers a loading volume of four cubic meters. With this, Ultre is addressing the need for emission-free, maneuverable delivery solutions for city centers. The vehicle has already been pre-approved, initial orders have been placed, and the company is currently looking for a production partner.

From the lab to series production – understanding materials is key

Behind the technology is the conviction to work with the material, not against it. Company founder Oskar Zięta originally developed the process out of necessity: as a doctoral student, he lacked the funds for conventional pressing tools. Instead, he used the natural reaction of metals to internal pressure – an idea that was initially ridiculed by the industry. But it was precisely this unconventional approach that led to a completely new production principle. Today, Ultre is the only company in the world that shapes sheet metal using internal pressure and holds its own patents for this process. The process is not only energy-efficient, but also conserves resources: material waste is minimized, heavy tools are no longer necessary, and the thin-walled construction results in significant weight savings – an advantage that is particularly important in vehicle construction and aerospace.

Between art, mobility, and space travel – applications with a future

In addition to the automotive industry, Ultre is also working on projects for extreme environments. In cooperation with research institutions, the technology is being tested for designs that could be used in space – where volume expansion and structural stability are required under extreme conditions. At the same time, the creative origin remains present: At the trade fair, the company is demonstrating the process using small “Hot Hearts” – sheet metal elements that can be inflated in the oven, thus illustrating the principles of internal pressure forming. The products are available as design objects and show that the technology is not only functional but also aesthetically impressive.

Conclusion – Ultre combines engineering artistry and material poetry

Ultre stands for an approach that combines art, technology, and sustainability. With free internal pressure forming, the company has established a process that sets new standards in lightweight construction – ecologically, creatively, and technologically. Whether as a load-bearing structure in an electric transporter, a component in space, or a design object in the living room: the principle remains the same – stability through air and material intelligence.